High-temperature manganic acid lithium cathode material and preparation method thereof

A type of lithium manganate and cathode material technology, which is applied in the field of high-temperature type lithium manganate cathode material and its preparation, can solve the problems of capacity decay, the high temperature cycle performance is not well solved, the cycle performance is very poor, and the like. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

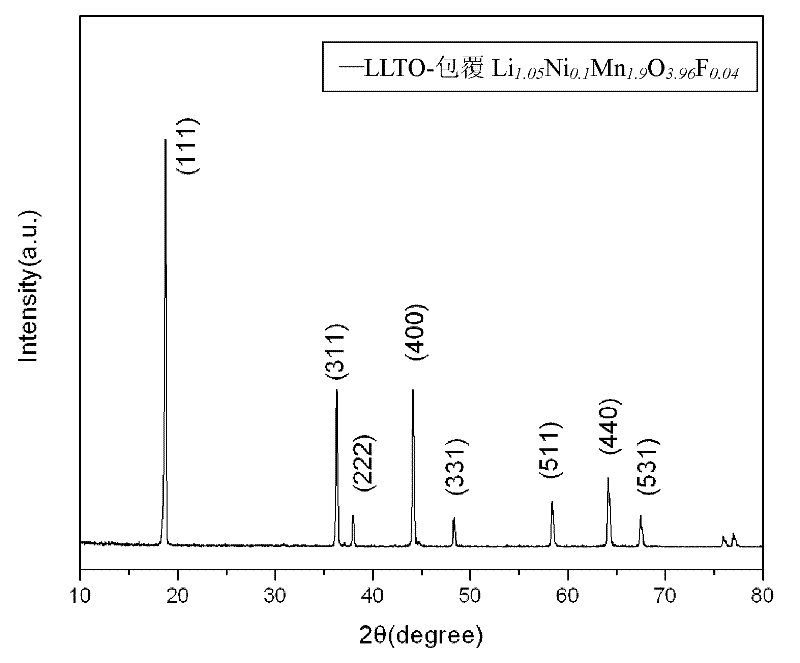

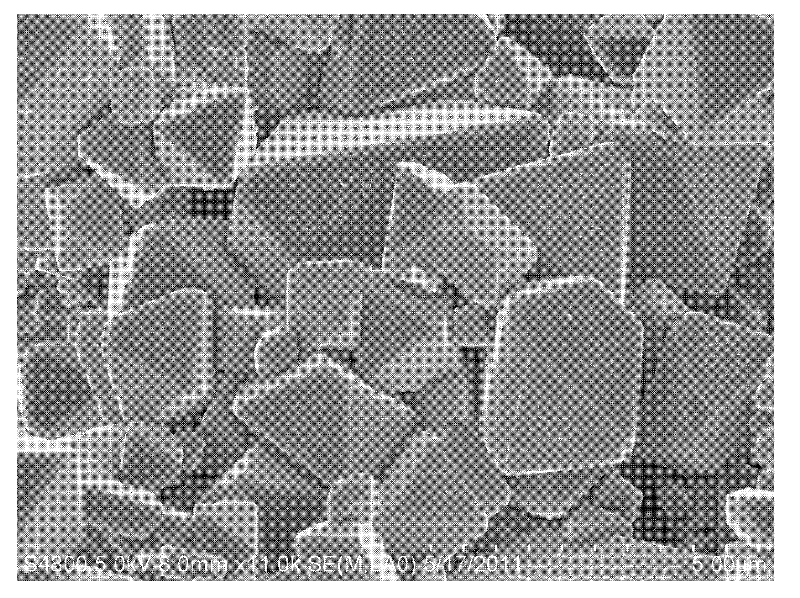

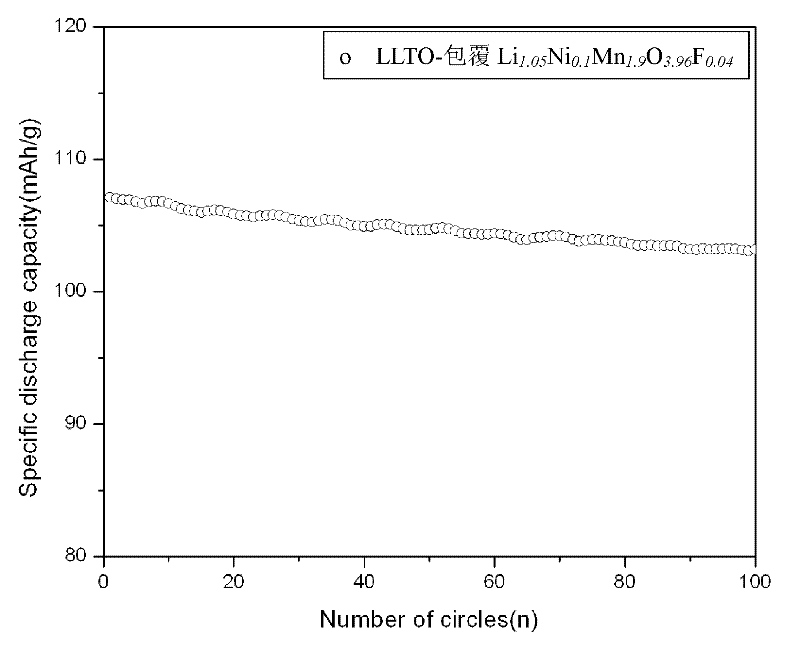

[0017] Product design: spinel lithium manganese oxide doped with anions and cations designed as Li 1.05 Ni 0.1 mn 1.9 o 3.96 f 0.04 , the solid electrolyte uses Li-La-Ti-O (abbreviated as LLTO) system Li 0.3 La 0.56 TiO 3 , by weight, the coated product contains 3.5% solid electrolyte.

[0018] The specific preparation process: the first step, doping anions and cations, preparing Li 1.05 Ni 0.1 mn 1.9 o 3.96 f 0.04 : Weigh the ingredients according to the molar ratio of each element, and the manganese source adopts battery-grade electrolytic Mn 2 O (purity 99.5%), lithium source adopts battery grade Li 2 CO 3 (purity 99.5%), the source material of doping cation adopts analysis pure cobalt acetate Ni (CH 3 COO) 2 4H 2 O (purity 99.5%), LiF (purity 99.5%) is used as the source material for doping anions. Use a high-speed ball mill to mix the raw materials evenly. After drying, calcinate at 820°C for 20 hours in an air atmosphere. After cooling, spinel lithium ma...

Embodiment 2

[0025] Product design: spinel lithium manganese oxide doped with anions and cations designed as Li 1.05 co 0.1 mn 1.9 o 3.96 S 0.04 , the solid electrolyte uses the Li-Al-Ti-P-O (abbreviated as LATP) system Li 1.01 al 0.2 Ti 1.8 (PO 4 ) 3 , the product after coating treatment contains 3.5wt% solid electrolyte.

[0026] The specific preparation process: the first step, doping anions and cations, preparing Li 1.05 co 0.1 mn 1.9 o 3.96 S 0.04 : Weigh the ingredients according to the molar ratio of each element, and the raw material is battery-grade electrolytic Mn 2 O (purity 99.5%), battery-grade Li 2 CO 3 (purity 99.5%), analytically pure cobalt acetate Co(CH 3 COO) 2 4H 2 O (purity 99.5%), MnS (purity 99.5%). Use a high-speed ball mill to mix the raw materials evenly. After drying, calcinate at 820°C for 20 hours in an air atmosphere. After cooling, spinel lithium manganate doped with anions and cations can be obtained. The second step, crystal form control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com