High-temperature manganic acid lithium cathode material and preparation method thereof

A type of lithium manganate and positive electrode material technology, applied in the field of high-temperature lithium manganate positive electrode material and its preparation, can solve the problems of capacity fading, delaying the pace of large-scale commercialization, poor cycle performance, etc., and achieve simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

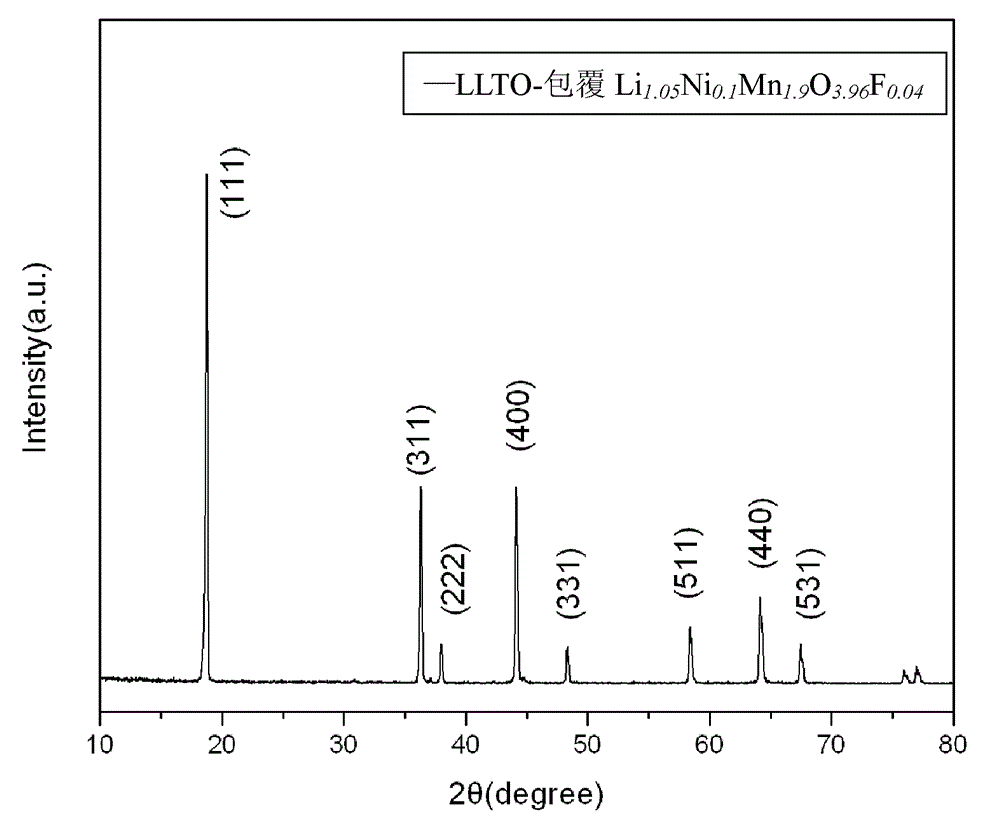

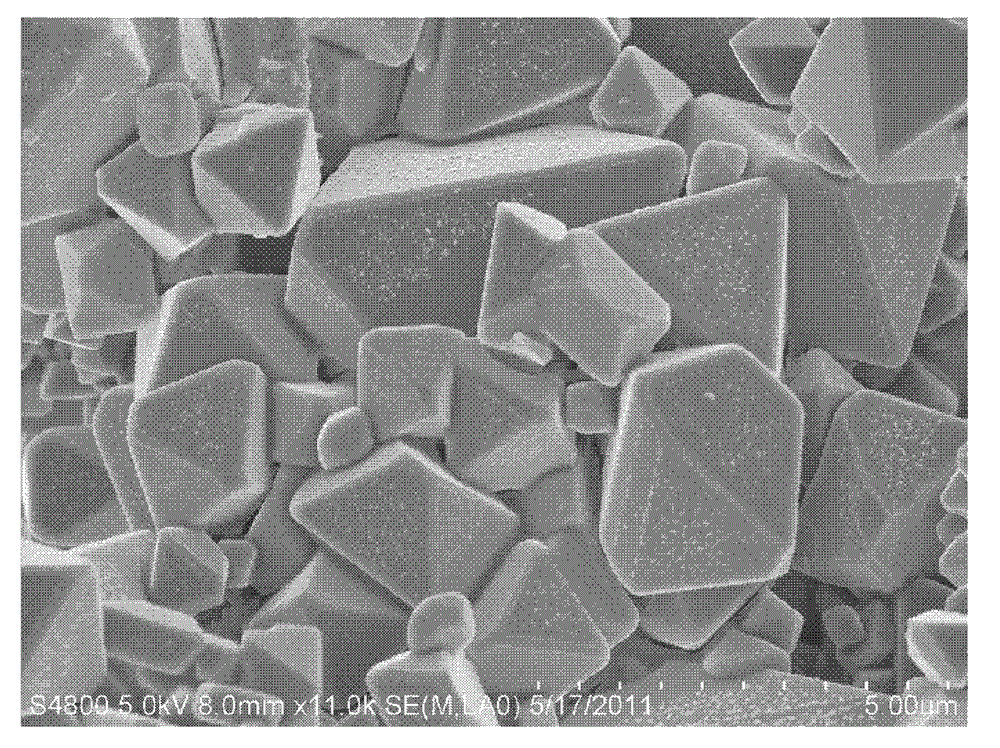

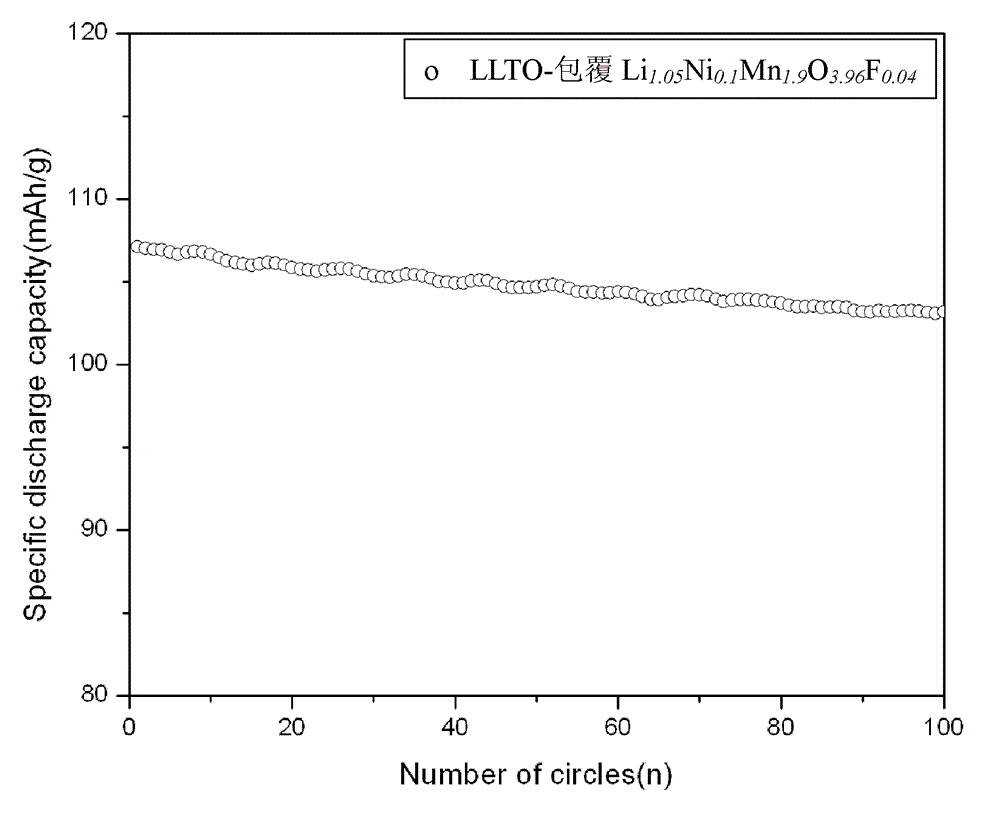

[0017] Product design: spinel lithium manganese oxide doped with anions and cations designed as Li 1.05 Ni 0.1 mn 1.9 o 3.96 f 0.04 , the solid electrolyte uses Li-La-Ti-O (abbreviated as LLTO) system Li 0.3 La 0.56 TiO 3 , by weight, the coated product contains 3.5% solid electrolyte.

[0018] The specific preparation process: the first step, doping anions and cations, preparing Li 1.05 Ni 0.1 mn 1.9 o 3.96 f 0.04 : Weigh the ingredients according to the molar ratio of each element, and the manganese source adopts battery-grade electrolytic Mn 2 O (purity 99.5%), lithium source adopts battery grade Li 2 CO 3 (purity 99.5%), the source material of doping cation adopts analysis pure cobalt acetate Ni (CH 3 COO) 2 4H 2 O (purity 99.5%), LiF (purity 99.5%) is used as the source material for doping anions. Use a high-speed ball mill to mix the raw materials evenly. After drying, calcinate at 820°C for 20 hours in an air atmosphere. After cooling, spinel lithium ma...

Embodiment 2

[0025] Product design: spinel lithium manganese oxide doped with anions and cations designed as Li 1.05 co 0.1 mn 1.9 o 3.96 S 0.04 , the solid electrolyte uses the Li-Al-Ti-P-O (abbreviated as LATP) system Li 1.01 Al 0.2 Ti 1.8 (PO 4 ) 3 , the product after coating treatment contains 3.5wt% solid electrolyte.

[0026] The specific preparation process: the first step, doping anions and cations, preparing Li 1.05 co 0.1 mn 1.9 o 3.96 S 0.04 : Weigh the ingredients according to the molar ratio of each element, and the raw material is battery-grade electrolytic Mn 2 O (purity 99.5%), battery-grade Li 2 CO 3 (purity 99.5%), analytically pure cobalt acetate Co(CH 3 COO) 2 4H 2 O (purity 99.5%), MnS (purity 99.5%). Use a high-speed ball mill to mix the raw materials evenly. After drying, calcinate at 820°C for 20 hours in an air atmosphere. After cooling, spinel lithium manganate doped with anions and cations can be obtained. The second step, crystal form control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com