Sr-doping oxide BiCuSeO thermoelectric material and preparation method thereof

A technology of thermoelectric materials and oxides, which is applied in the direction of lead-out wire materials of thermoelectric devices and the manufacture/processing of thermoelectric devices. And the effect of short molding time, high thermoelectric figure of merit and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

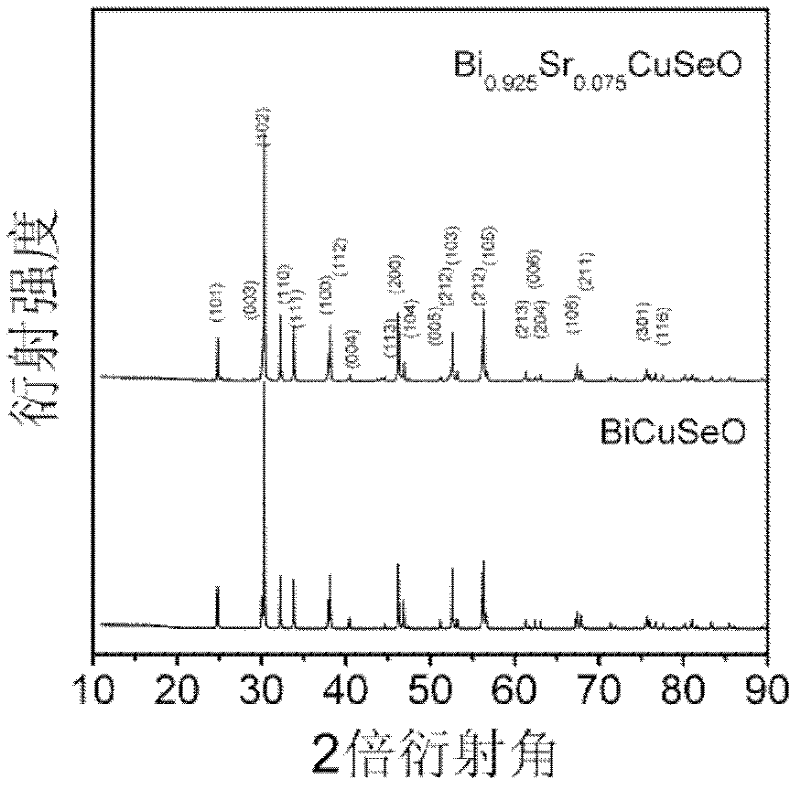

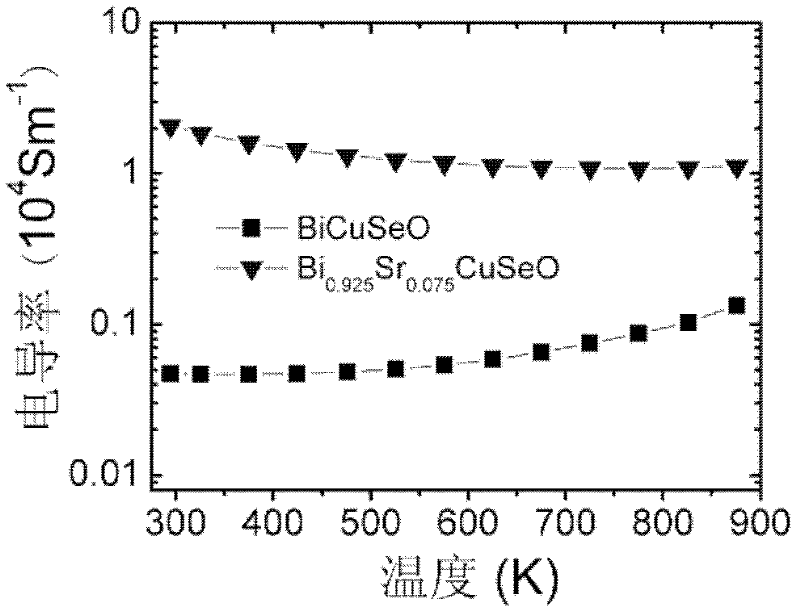

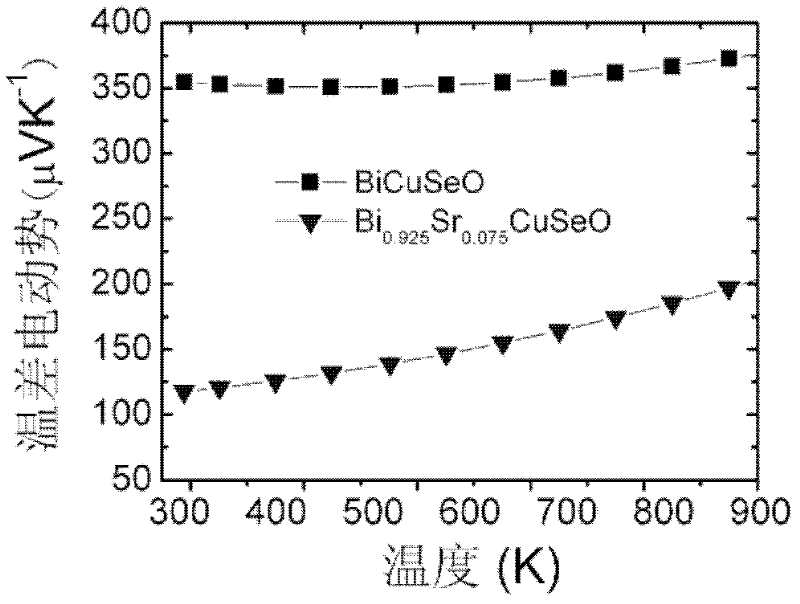

[0020] The invention provides a Sr-doped oxide BiCuSeO thermoelectric material and a preparation method thereof. The chemical formula of the Sr-doped oxide BiCuSeO thermoelectric material is Bi 1-x Sr x CuSeO, x=0.025-0.125, preferably, x=0.025-0.075. The electrical conductivity of the thermoelectric material ranges from 470 to 48000 Sm -1 , the variation range of thermoelectric potential is +100~+375μVK -1 , the variation range of thermal conductivity is 0.45~1.05Wm -1 K -1 , the maximum dimensionless thermoelectric figure of merit is 0.76 at 873K.

[0021] The above-mentioned Sr-doped oxide BiCuSeO thermoelectric material is prepared by the following method:

[0022] (1) Raw material preparation: using Bi 2 o 3 (purity of 99.9%), SrO (purity of 99.99%), Cu (purity of 99.99%), Se (purity of 99.99%) and Bi (purity of 99.99) powders as initial raw materials, according to Bi 2 o 3 : SrO: Cu: Se: Bi=(1 / 3-x): x: 1: 1: [1-2*(1 / 3-x)] atomic ratio batching, x=0.025~0.125.

...

Embodiment 1

[0028] Example 1: A kind of Sr-doped oxide BiCuSeO thermoelectric material Bi0.975Sr0.025CuSeO is prepared by the method provided by the present invention, and the specific preparation steps are as follows:

[0029] (1) Prepare raw materials: according to Bi 2 o 3 :SrO:Cu:Se:Bi=(1 / 3-x):x:1:1:[1-2*(1 / 3-x)] atomic ratio batching, x=0.025. Bi 2 o 3(purity 99.9%), SrO (purity 99.99%), Cu (purity 99.99%), Se (purity 99.99%) and Bi (purity 99.99) are powders.

[0030] (2) Mix raw materials. The above raw materials were put together into a ball mill and ball milled at 100 rpm for 1 h.

[0031] (3) Put the uniformly mixed powder into a steel mold with a diameter of 10-20 mm and press it into a disc under a pressure of 150 MPa.

[0032] (4) Place the cold-pressed wafer in a quartz tube and sinter it at 300°C for 240 hours at a heating rate of 180°C per hour to obtain a Sr-doped oxide BiCuSeO with the same diameter as the mold and a height of 4mm. bulk material.

[0033] (5) T...

Embodiment 2

[0035] Example 2: A kind of Sr-doped oxide BiCuSeO thermoelectric material Bi0.925Sr0.075CuSeO is prepared by the method provided by the present invention, and the specific preparation steps are as follows:

[0036] (1) Prepare raw materials: according to Bi 2 o 3 :SrO:Cu:Se:Bi=(1 / 3-x):x:1:1:[1-2*(1 / 3-x)] atomic ratio batching, x=0.075. Bi 2 o 3 (purity 99.9%), SrO (purity 99.99%), Cu (purity 99.99%), Se (purity 99.99%) and Bi (purity 99.99) are powders.

[0037] (2) Mix raw materials. The above raw materials were put together into a ball mill and ball milled at 100 rpm for 50 h.

[0038] (3) Put the uniformly mixed powder into a steel mold with a diameter of 10-20 mm and press it into a disc under a pressure of 250 MPa.

[0039] (4) Place the cold-pressed wafer in a quartz tube and sinter it at 700°C for 48 hours at a heating rate of 40°C per hour to obtain a Sr-doped oxide with a diameter of 10-20mm and a height of 6mm BiCuSeO bulk material.

[0040] (5) Then Bi 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com