Preparation method and application of graded porous carbon material

A technology of hierarchical porous and carbon materials, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of cumbersome preparation process, unfavorable industrial production, difficulty in large-scale preparation of porous carbon materials, etc., and achieve simplified preparation process, excellent electrochemical performance, conductive sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weighing 810 mg of zinc oxide nanoparticles (first raw material) and 1.64 g of 2-methylimidazole (second raw material), ball milled at a speed of 200 rpm for 8 hours to obtain a carbon precursor material. Put the precursor material in N 2 Under the protection of inert gas, after holding at 200oC for 2h and then calcining at 950oC for 10h, a nitrogen-doped hierarchical porous carbon material was obtained.

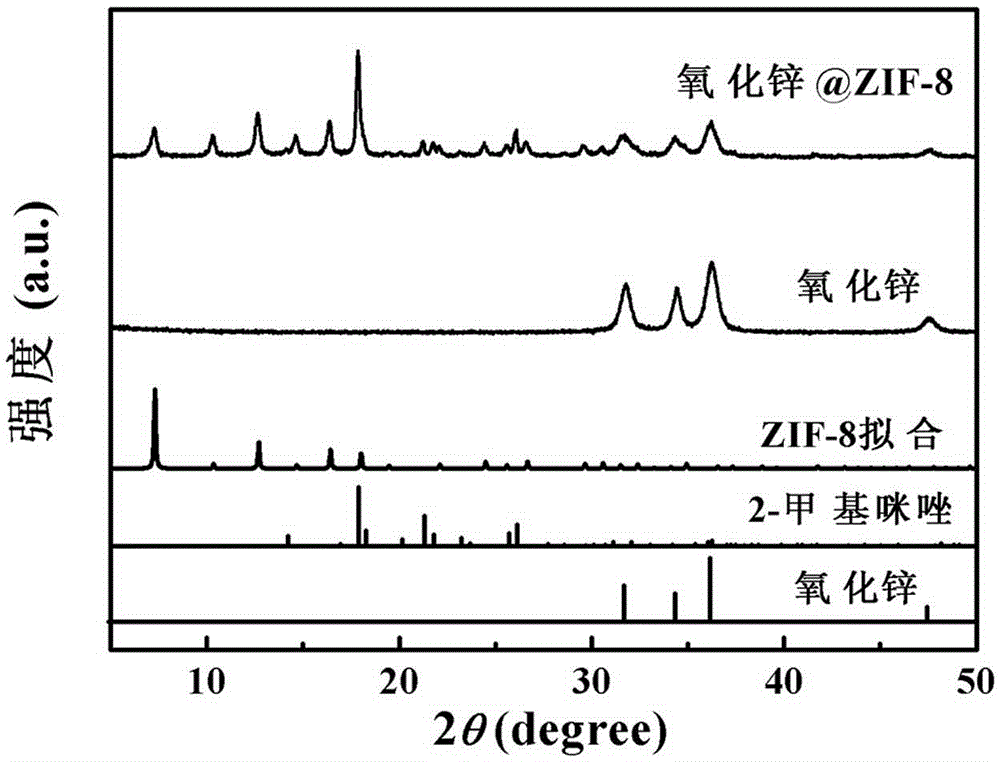

[0026] attached figure 1 It is the XRD spectrum of the precursor material obtained in Example 1. The XRD pattern shows that the product after ball milling is a composite material of ZIF-8 and ZnO, indicating that part of ZnO is transformed into ZIF-8. And compared with the raw material, the intensity of the diffraction peak of zinc oxide in the precursor material is significantly weaker, and the half-peak width is increased, which further confirms that part of the zinc oxide is transformed into ZIF-8, thereby forming a core-shell structure.

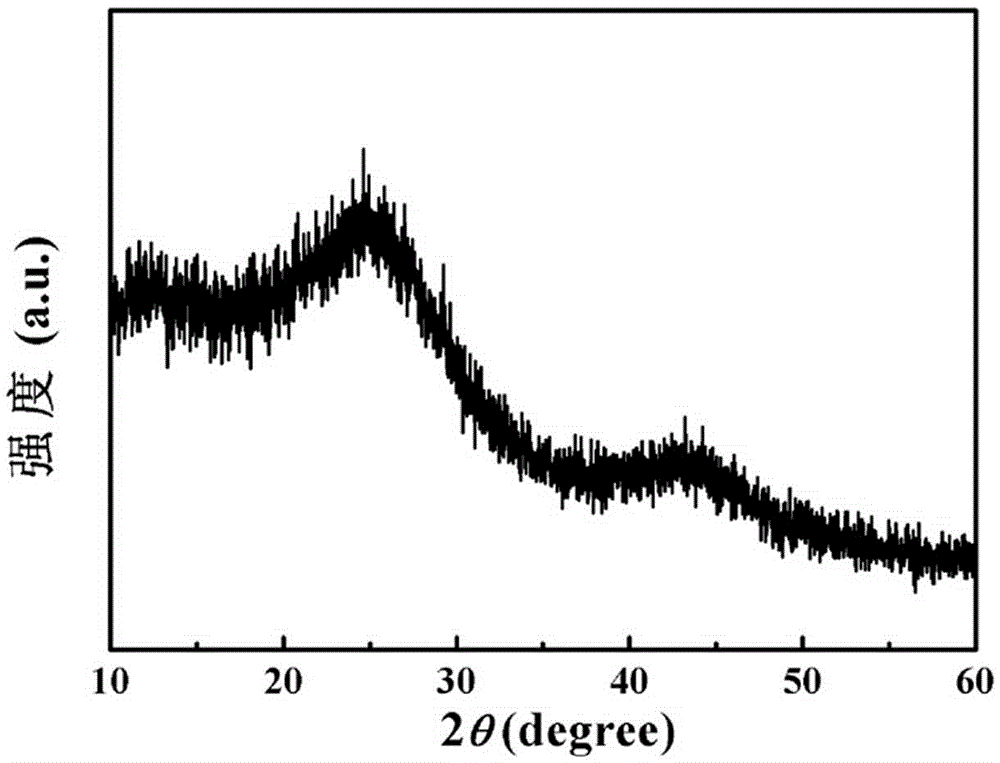

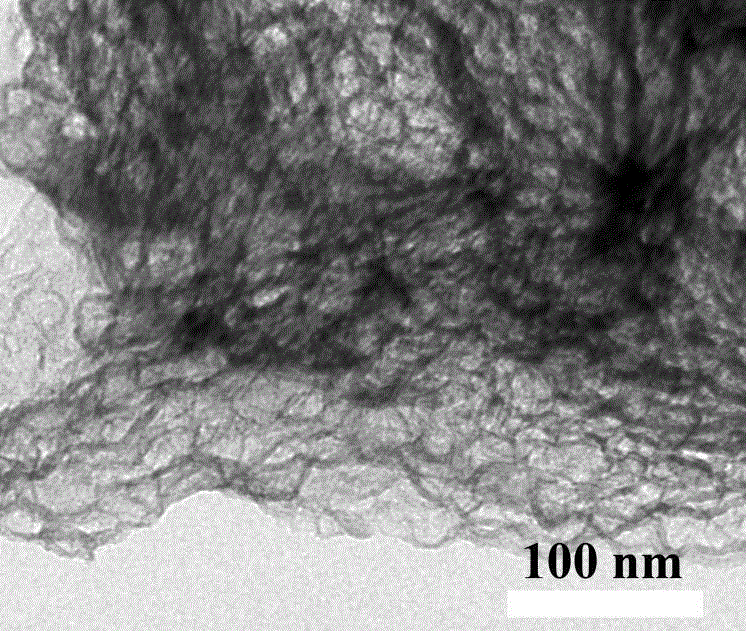

[0027] attached figu...

Embodiment 2

[0031] Weigh 810mg of zinc oxide (the first raw material) and 0.41g of 2-methylimidazole (the second raw material), ball mill for 8 hours at a speed of 200 rpm, and then 2Under the protection of inert gas, heat preservation at 200oC for 2h and then calcining at 950oC for 10h, a hierarchically porous carbon material can be obtained, and the yield of hierarchically porous carbon is lower than that of Example 1.

Embodiment 3

[0033] Weigh 810mg of zinc oxide (the first raw material) and 13.12g of 2-methylimidazole (the second raw material), ball mill for 8 hours at a speed of 200 rpm, and then 2 Under the protection of inert gas, after holding at 200oC for 2h and then calcining at 950oC for 10h, a hierarchically porous carbon material can be obtained, and the yield of hierarchically porous carbon is higher than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com