Method for preparing nitrogen-doped graphene and nitrogen-doped graphene

A nitrogen-doped graphene and nitrogen precursor technology is applied in the preparation of nitrogen-doped graphene and in the field of nitrogen-doped graphene, which can solve the problems of high cost, difficult industrial production, complicated technology, etc., and achieves low price and easy availability. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

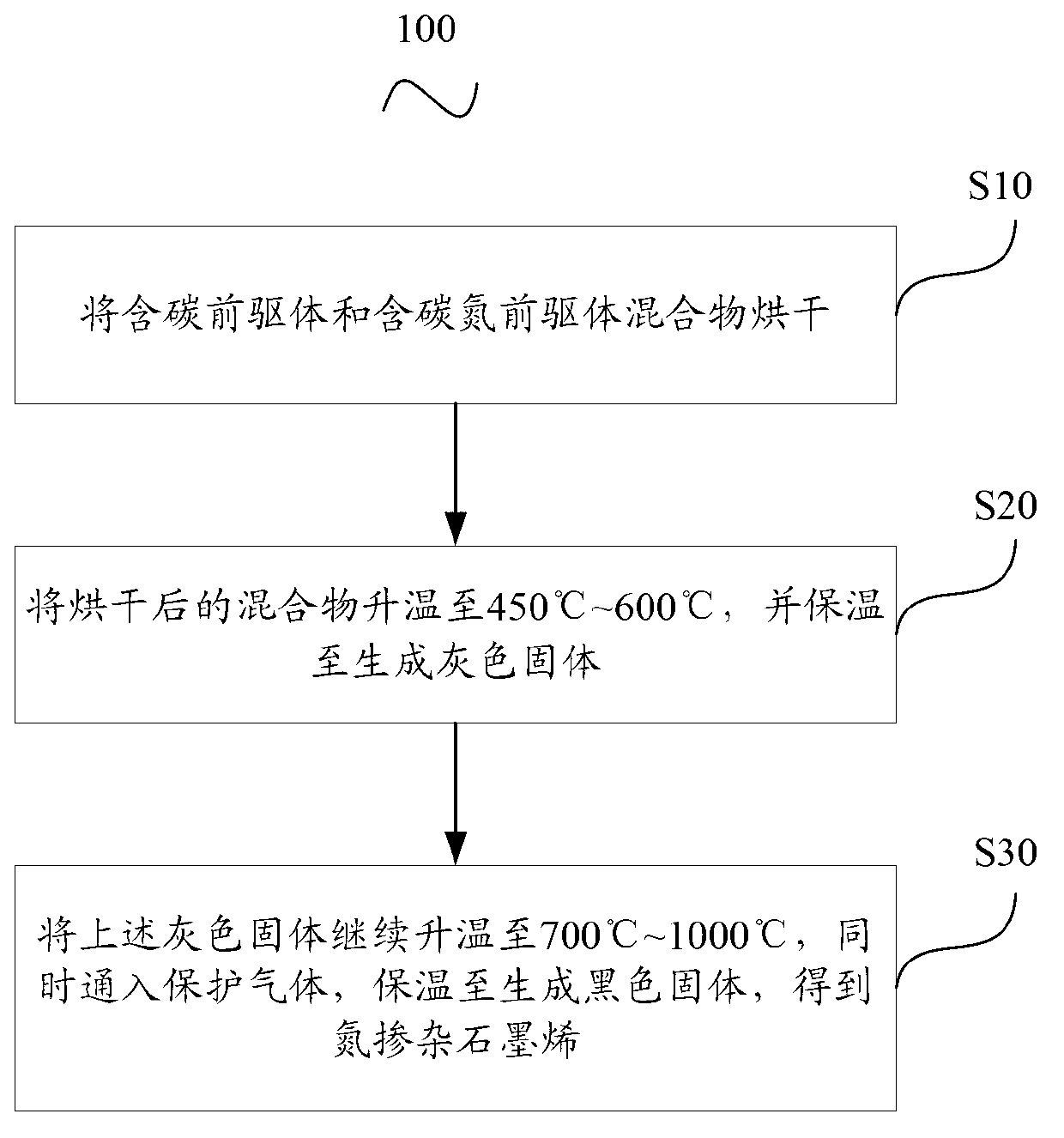

[0032] see figure 1 , figure 1 The step flowchart 100 of the preparation method of the nitrogen-doped graphene provided by the embodiment of the present invention, from figure 1 Visible in, the preparation method of nitrogen-doped graphene comprises the following steps:

[0033] Step S10: drying the mixture of the carbon-containing precursor and the carbon-nitrogen-containing precursor.

[0034] In this embodiment, the mass of the mixture of the carbon-containing precursor and the carbon-nitrogen-containing precursor is 3 g to 1000 g.

[0035] In this embodiment, the carbon-containing precursor is a carbon-containing sugar molecule, and the carbon-nitrogen-containing precursor is a carbon-nitrogen-containing organic small molecule. Preferably, the carbon-containing sugar molecule is at least one of glucose or sucrose, and the carbon-nitrogen-containing organic small molecule is at least one of melamine, cyanamide, dicyandiamide, urea, diuret, trichloroethylamine ; Preferab...

Embodiment 1

[0047] The steps included in the preparation method of nitrogen-doped graphene provided in Example 1 of the present invention are as follows:

[0048] Put 10g of melamine and 0.5g of glucose into the crucible after mixing evenly, and dry at a suitable temperature; put the dried mixture into a heating furnace, and heat up to 550°C at a rate of 5°C / min. React at high temperature for more than 3 hours until a gray solid is produced; then transfer the above gray solid to a tube furnace, and at the same time pass the protective gas Ar at a rate of 200 sccm, and keep it at 100 ° C for more than 30 min, and then at 10 ° C / min The heating rate was increased to 800°C, and the reaction was carried out at this temperature for 1 hour until a black solid was formed, and cooled in the air environment to obtain nitrogen-doped graphene. The graphene obtained according to the above preparation method has an atomic ratio of carbon / nitrogen of 2.9.

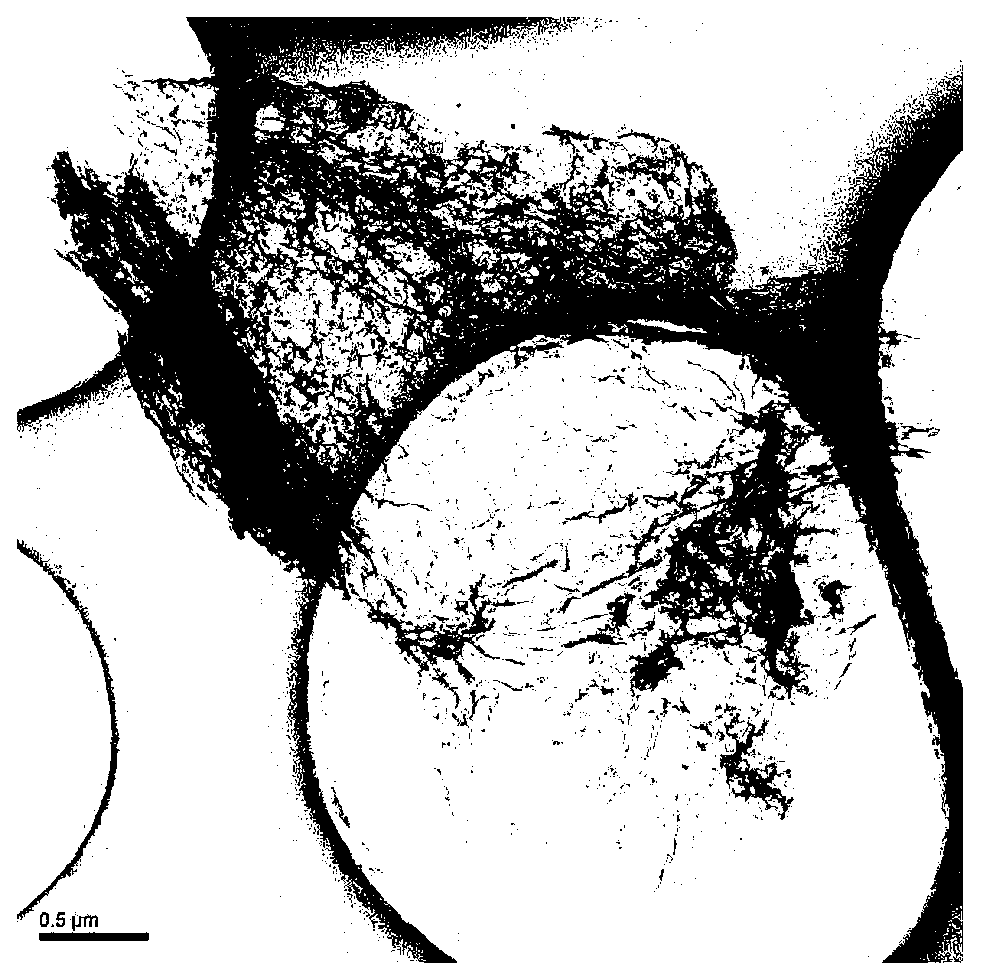

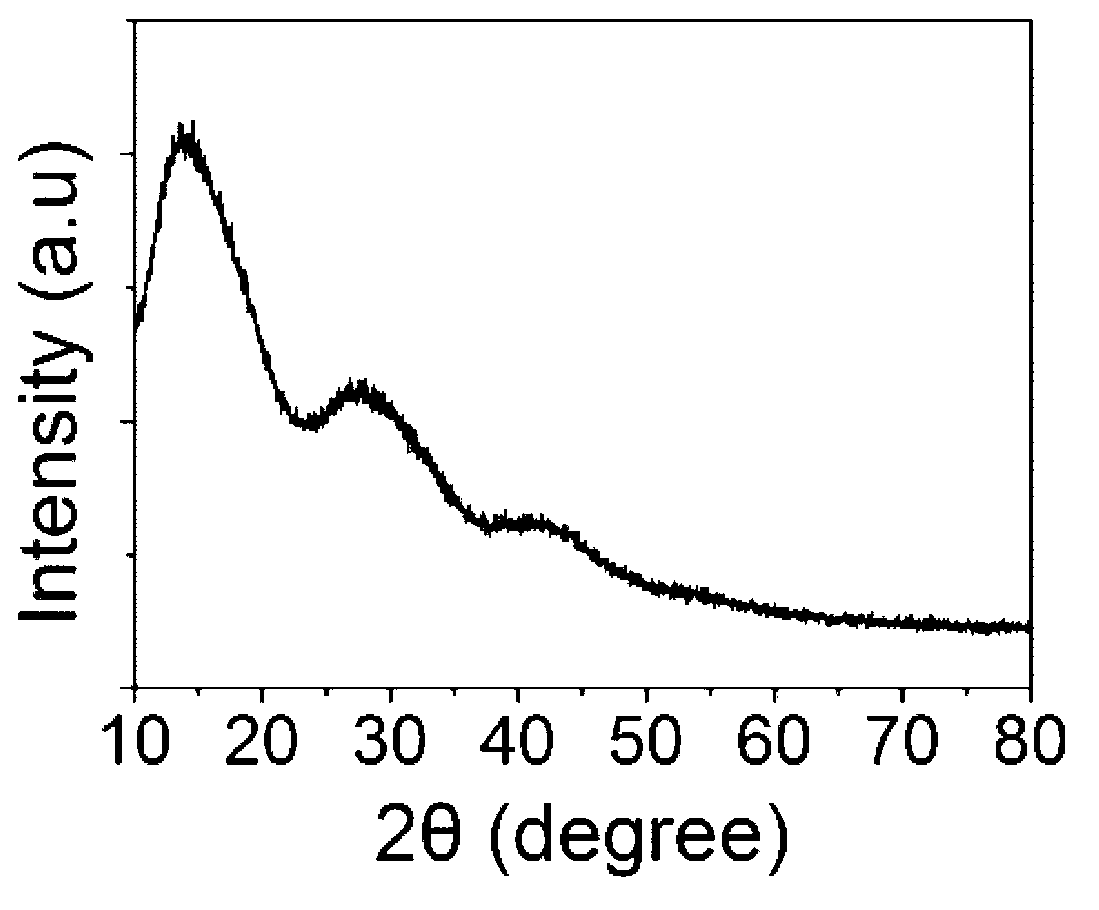

[0049] see figure 2 , image 3 and Fi...

Embodiment 2

[0051] The steps included in the preparation method of nitrogen-doped graphene provided by Example 2 of the present invention are as follows:

[0052] Put 10g of urea and 0.5g of glucose into the crucible after mixing evenly, and dry at a suitable temperature; put the dried mixture into a heating furnace, and heat up to 550°C at a rate of 5°C / min. React at high temperature for more than 3 hours until a gray solid is produced; then transfer the above gray solid to a tube furnace, and at the same time pass the protective gas Ar at a rate of 200 sccm, and keep it at 100 ° C for more than 30 min, and then at 10 ° C / min The heating rate was increased to 800°C, and the reaction was carried out at this temperature for 1 hour until a black solid was formed, and cooled in the air environment to obtain nitrogen-doped graphene. The atomic ratio of carbon / nitrogen in the graphene obtained according to the above preparation method is 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com