Method for preparing Cu2Se thermoelectric material by low-temperature solid-phase reaction

A technology of solid-state reaction and thermoelectric materials, applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problem of unfavorable material phase composition regulation and thermoelectric performance optimization, optimization research of limiting material thermoelectric performance, very It is difficult to accurately control the content of Se in the product, etc., to achieve the effect of uniform distribution of product components, low cost of raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] a Cu 2 The solid-phase reaction preparation method of Se thermoelectric material, it comprises the steps:

[0027] 1) Take Cu powder and Se powder as raw materials, weigh Cu powder and Se powder according to the molar ratio of Cu powder and Se powder as 2:1, weigh the total amount to 4.1212g, and mix the raw material powder in a mortar Uniform, get mixed powder;

[0028] 2) Press the mixed powder into a cylindrical block with a diameter of 10mm at a pressure of 10MPa on a tablet press, place the cylindrical block in a graphite crucible (15mm in outer diameter), vacuumize and seal it in quartz glass tube (with an inner diameter of 17 mm and an outer diameter of 20 mm), and then placed in a muffle furnace for solid-state reaction, using a heating rate of 2 °C / min from 200 °C to 650 °C, and then holding at 650 °C for 12 hours, the end of the holding After cooling with the furnace, the resulting product is ground into powder;

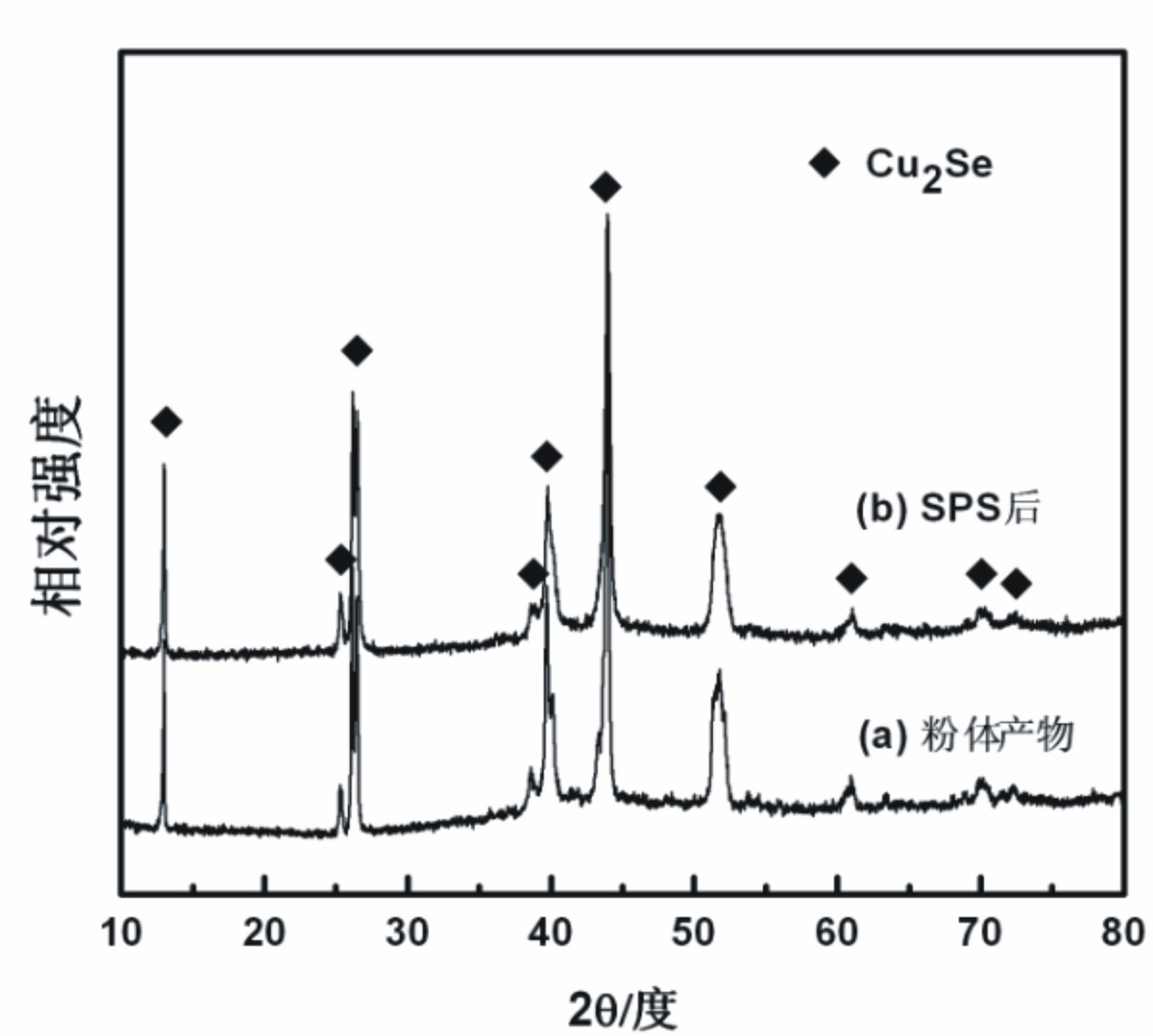

[0029] The XRD pattern of the powder sample...

Embodiment 2

[0033] a Cu 2 The solid-phase reaction preparation method of Se thermoelectric material, it comprises the steps:

[0034] 1) Take Cu powder and Se powder as raw materials, weigh Cu powder and Se powder according to the molar ratio of Cu powder and Se powder as 2:1, weigh the total amount to 4.1212g, and mix the raw material powder in a mortar Uniform, get mixed powder;

[0035] 2) Press the uniformly mixed powder into a cylindrical block with a pressure of 12MPa on a tablet press, place the cylindrical block in a graphite crucible, vacuumize and seal it in a quartz glass tube, and then place it in a muffle Carry out solid-state reaction in the furnace, use a heating rate of 3°C / min to raise the temperature from 200°C to 700°C, and then keep it at 700°C for 12 hours. After the heat preservation is completed, cool with the furnace, and grind the obtained product into powder;

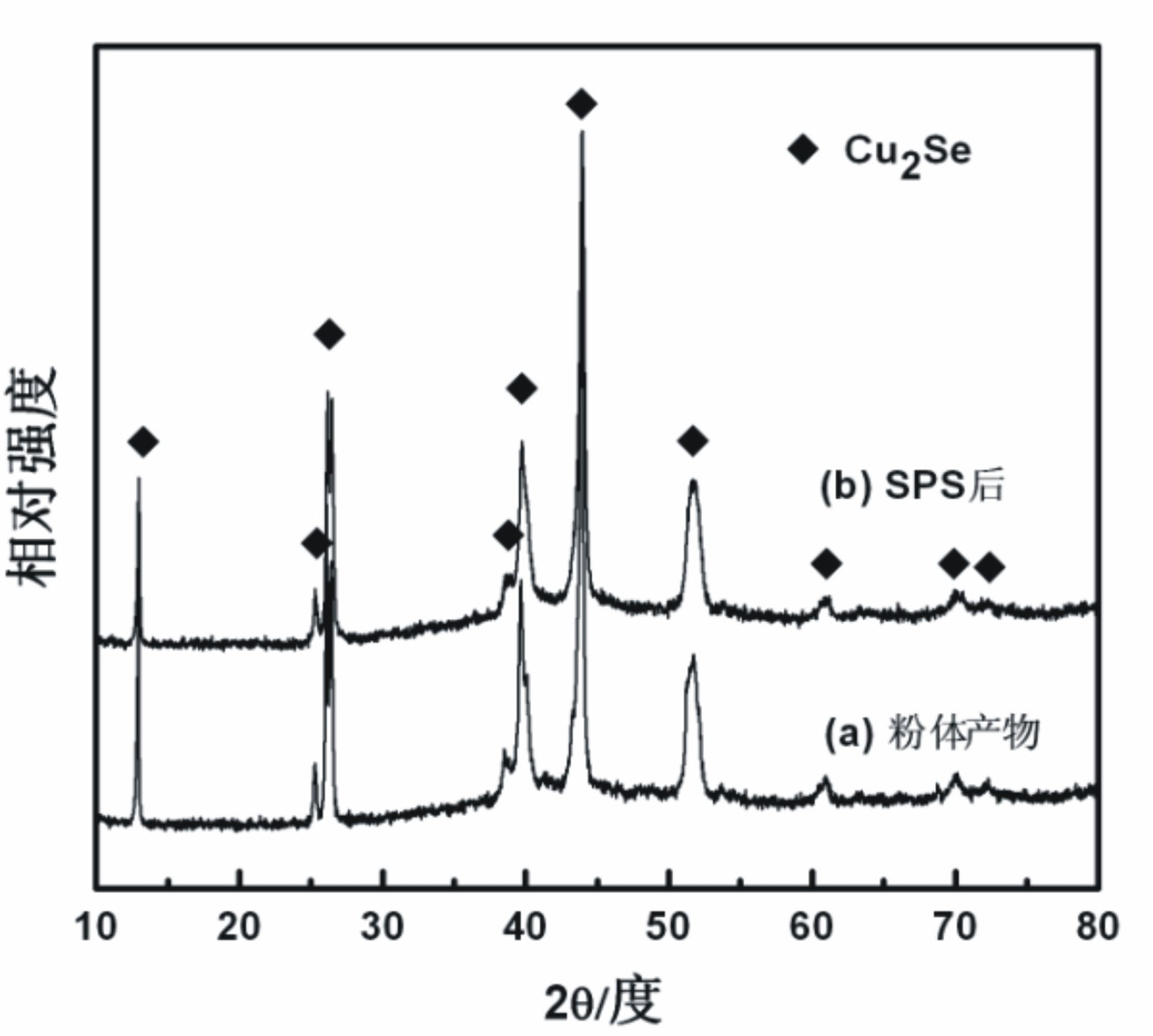

[0036] The XRD spectrum of the powder sample obtained through solid phase reaction is shown in figu...

Embodiment 3

[0040] a Cu 2 The solid-phase reaction preparation method of Se thermoelectric material, it comprises the steps:

[0041] 1) Take Cu powder and Se powder as raw materials, weigh Cu powder and Se powder according to the molar ratio of Cu powder and Se powder as 2:1, weigh the total amount to 4.1212g, and mix the raw material powder in a mortar Uniform, get mixed powder;

[0042] 2) Press the mixed powder into a cylindrical block with a pressure of 15 MPa on a tablet press, place the cylindrical block in a graphite crucible, vacuumize and seal it in a quartz glass tube, and then place it in a muffle furnace Carry out solid-state reaction, use a heating rate of 5°C / min to raise the temperature from 200°C to 750°C, then keep it at 750°C for 12 hours, cool with the furnace after the heat preservation, and grind the obtained product into powder;

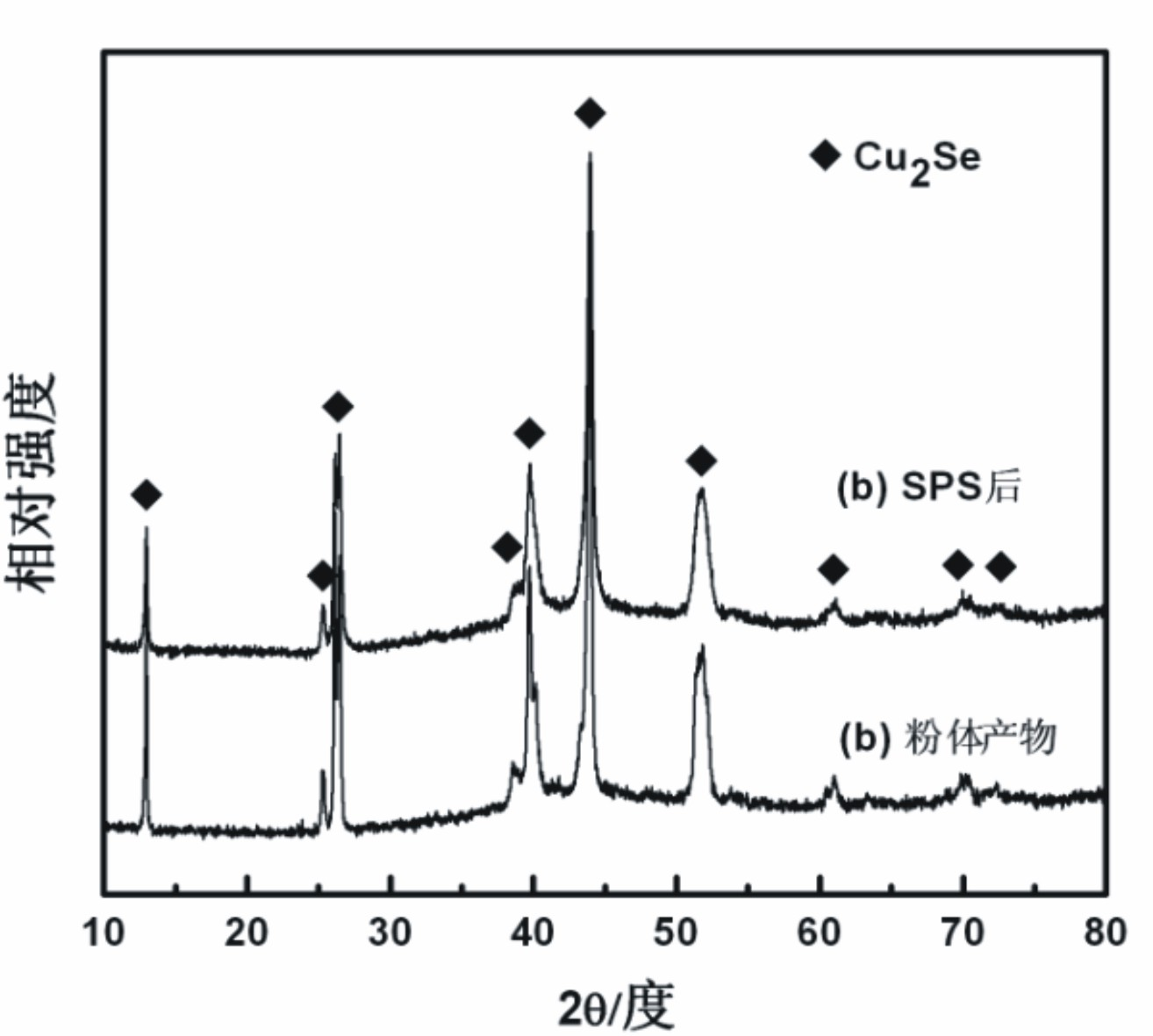

[0043] The XRD spectrum of the powder sample obtained through the solid phase reaction is shown in image 3 In (a), by image 3 In (a),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com