Omnibearing growing method for KDP (Potassium Dihydrogen Phosphate) crystals

A growth method and crystal growth technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor crystal quality and slow crystal growth speed, and achieve good crystal structure and quality, simple growth process, and growth The effect of easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

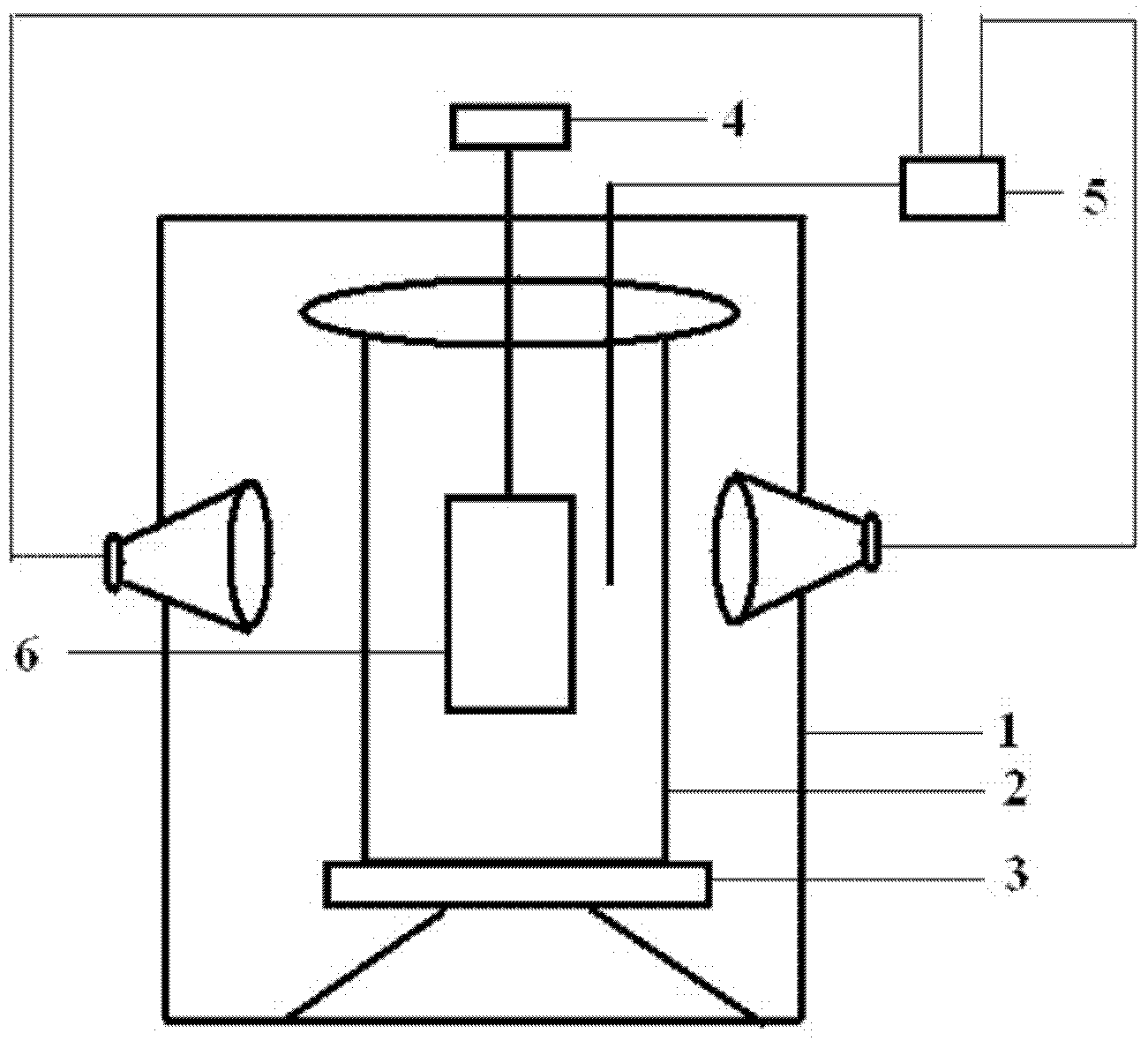

Method used

Image

Examples

Embodiment

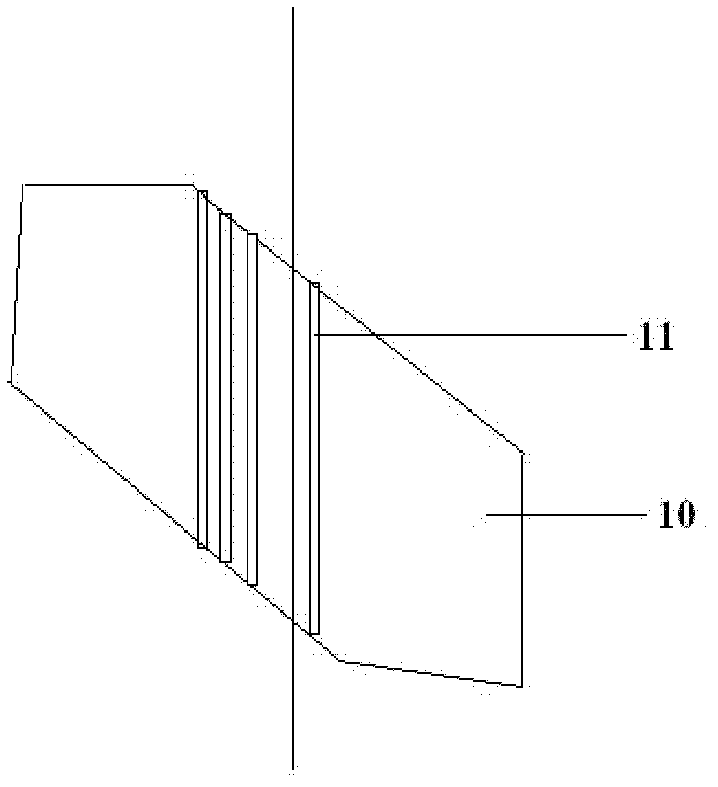

[0019] The specific steps of this embodiment include solution preparation, solution filtration, solution overheating, seed crystal treatment, seed crystal fixation, seed crystal cone forming, crystal growth and crystal cutting eight process steps, and the specific steps are:

[0020] (1) Solution preparation: according to the solubility formula s t =(171+4.7t / °C) g / kg calculation, weigh 1500g double distilled water and add 1000g superior grade pure ADP raw material to prepare a solution whose saturation point is 40-50°C, and adjust the pH value of the solution to 2.4 with phosphoric acid;

[0021] (2) Solution filtration: filter the solution with filter papers of 0.45 μm and 0.22 μm respectively to obtain a pure solution;

[0022] (3) Overheating of the solution: overheating the pure solution at a constant temperature of 20° C. above the saturation point for 24 hours to obtain a growth solution;

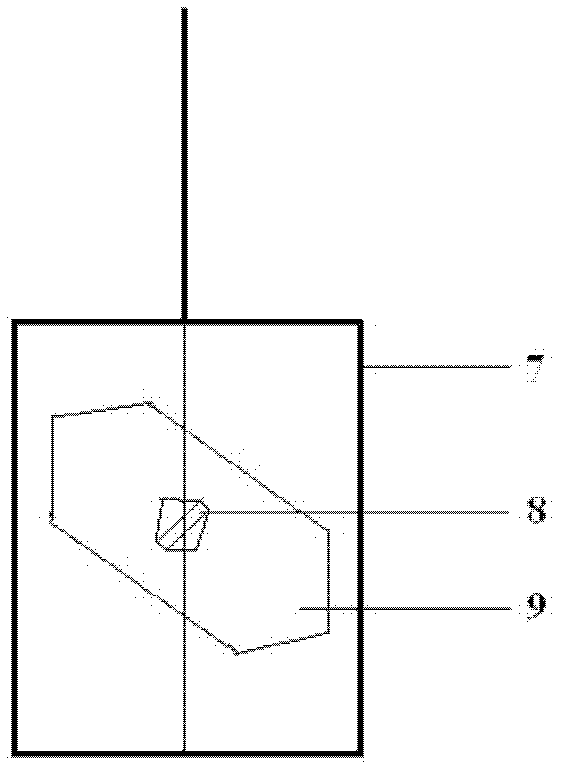

[0023] (4) Seed crystal treatment: cut the seed crystal into 8×8×2mm seed cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com