Seed crystal support and silicon carbide single crystal growth method

A technology of seed crystal and thermal conductive layer, applied in the field of silicon carbide crystal preparation, can solve problems such as single crystal growth multi-nucleation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

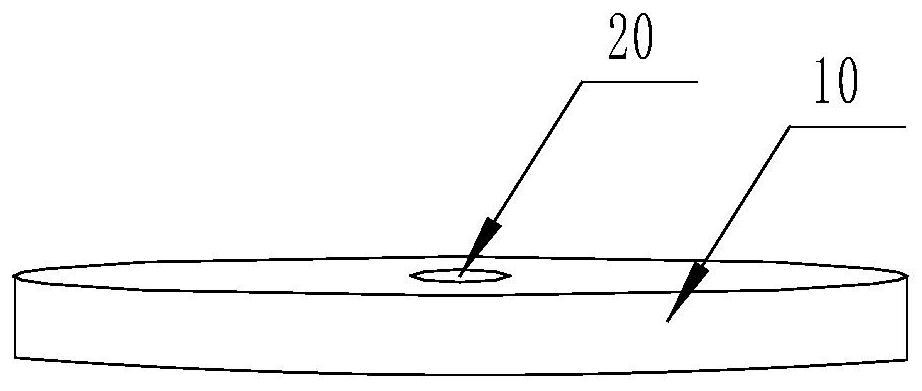

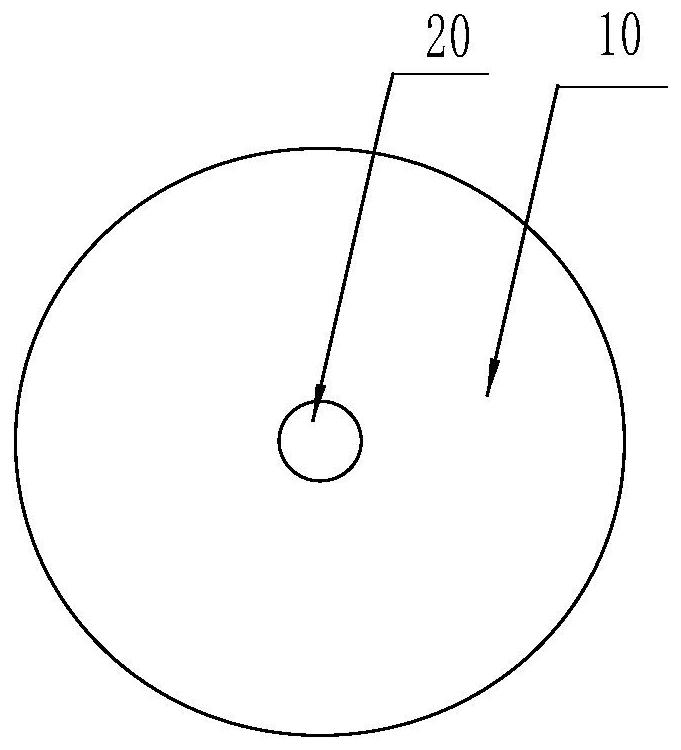

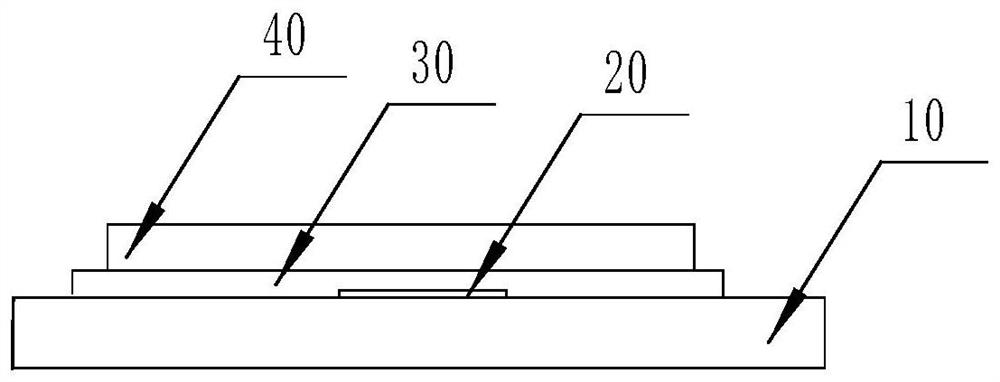

[0037] figure 1 A schematic diagram of the basic structure of a seed crystal holder provided in the embodiment of the present application. figure 2 for figure 1 Schematic diagram of the upper surface structure of the seed holder in . Such as figure 1 with 2 As shown, the seed crystal holder includes a graphite seed crystal holder base 10, wherein a heat conduction layer 20 is provided in the central area of the side of the seed crystal holder base 10 for bonding the seed crystal, specifically, the heat conduction layer 20 is The heat conduction film structure provided on the surface of the seed crystal support base 10, the heat conduction film includes a single-layer film structure or a multi-layer film structure. At the same time, it is required that the heat conduction layer 20 and the seed crystal support base 10 have a certain thermal conductivity difference, and the thermal conductivity of the material of the heat conduction layer 20 is greater than that of the see...

Embodiment 2

[0045] Since the larger the surface area of the thermal conduction layer 20 on the seed crystal support substrate 10 is, the more obvious the effect of regulating the temperature field on the surface of the seed crystal is, but the larger the area, the greater the number of nucleation in the region will increase. Therefore, on the basis of the first embodiment, this embodiment also provides another seed crystal holder.

[0046] Figure 4 A schematic diagram of the basic structure of another seed crystal holder provided in the embodiment of the present application. Such as Figure 4 As shown, the seed crystal holder provided in this example includes a seed crystal holder base 10, and a groove is opened in the central area of one side of the seed crystal holder base 10 for bonding the seed crystal, and the thermal conduction layer 20 is filled in the groove. At the same time, it is required that the heat conduction layer 20 and the seed crystal support base 10 have a certa...

Embodiment 3

[0051] In the above-mentioned embodiments, the thermal conduction layer 20 mainly dissipates heat with its surrounding crystal support base and adhesive through heat conduction to realize the purpose of regulating its temperature field. Compared with other areas of the seed crystal, the temperature difference is larger. This embodiment provides another seed crystal holder on the basis of the first and second embodiments above.

[0052] Figure 5 A schematic diagram of the basic structure of another seed crystal holder provided in the embodiment of the present application. Such as Figure 5 As shown, the seed crystal holder provided in this example includes a seed crystal holder base 10 , and a through hole is opened in the central area of the seed crystal holder base 10 , and the heat conduction layer 20 is filled in the through hole. At the same time, it is required that the heat conduction layer 20 and the seed crystal support base 10 have a certain thermal conductivity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com