Amidoximated mesoporous silica microsphere adsorbent and preparation method thereof

A mesoporous silica and microsphere adsorption technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of high production cost, low production efficiency, and low adsorption capacity , to achieve the effects of short adsorption equilibrium time, improved production efficiency, and high uranium adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

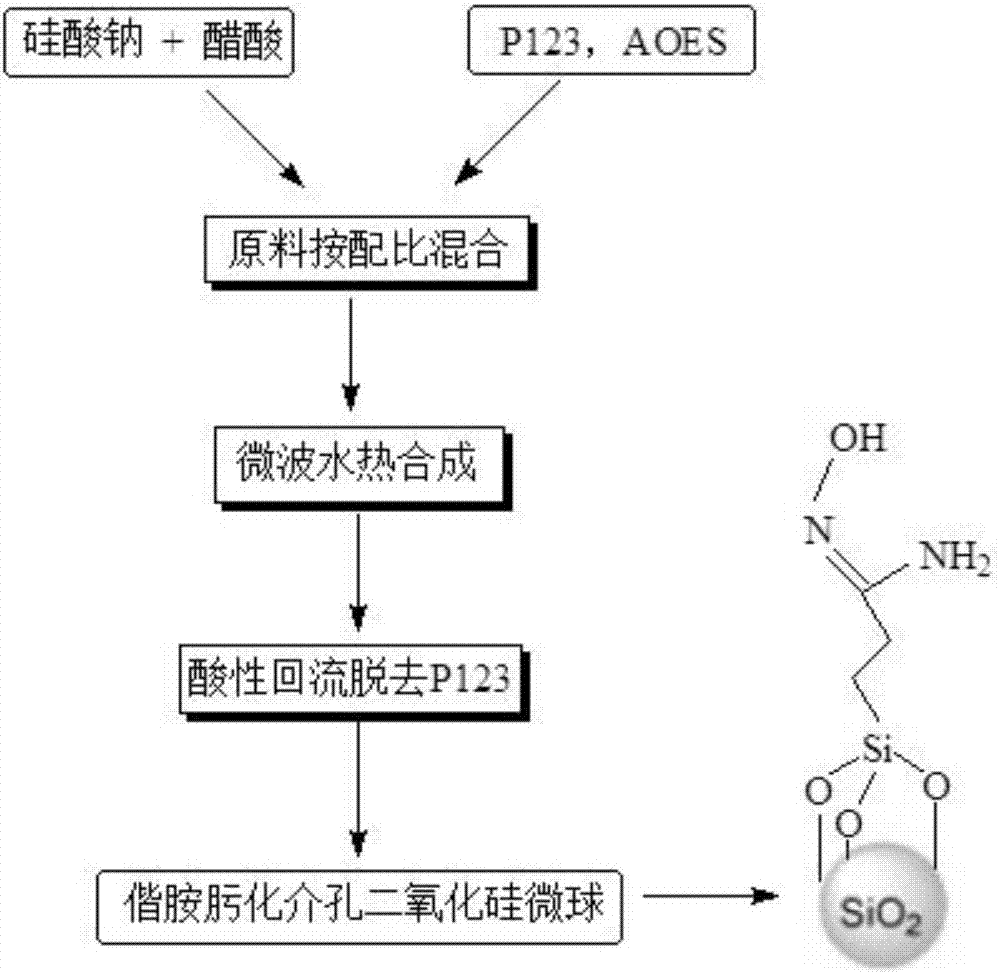

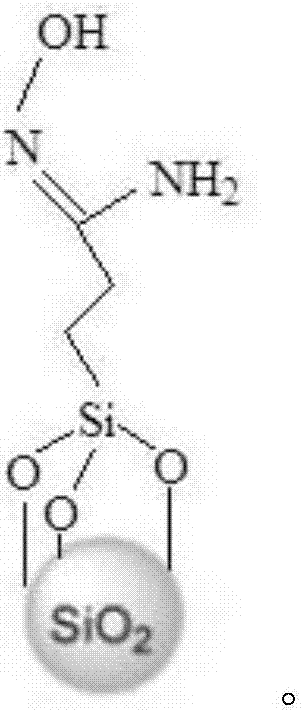

[0023] A preparation method of amidoxime mesoporous silica microsphere adsorbent, the specific steps are as follows:

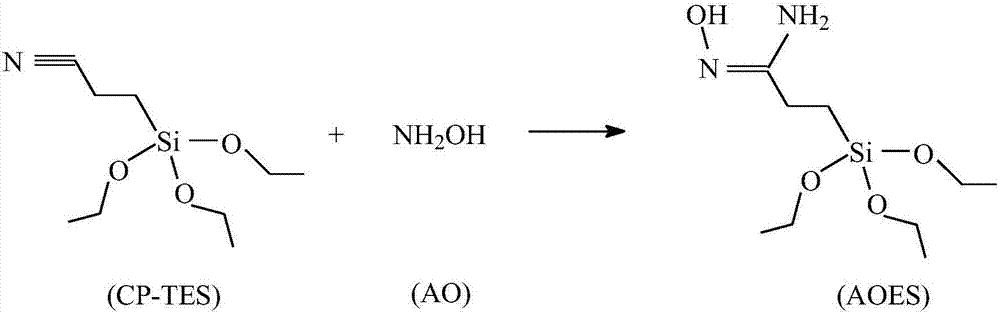

[0024] (1) Synthesis of amidoximated organosilane functionalization reagent (AOES)

[0025] Add 120 mg (3-cyanopropyl) triethoxysilane (CP-TES), 387.2 mg hydroxylamine (AO) and 275 mg Na 2 CO 3 , heated under reflux at 70°C for 12 hours, and purified by Soxhlet extraction to obtain an amidoximated organosilane functional reagent ((3-amidoximopropyl)triethoxysilane), the reaction formula is as follows:

[0026]

[0027] (2) Preparation of amidoxime mesoporous silica microsphere adsorbent (according to AOES / Na 2 SiO 3 Mass ratio 10wt.% implementation)

[0028] Take 60mL of absolute ethanol, 80mL of deionized water, 30mL of acetic acid solution (25wt.%) and 2.0mL of P123 and place them in a container for rapid stirring and mixing. While stirring, add 50mL of sodium silicate solution (containing 10.0g of silicon NaOH) and 1.0 g of AOES were thoroughly mixe...

Embodiment 2

[0031] A preparation method of amidoxime mesoporous silica microsphere adsorbent, the specific steps are as follows:

[0032] (1) Synthesis of amidoximated organosilane functionalization reagent (AOES)

[0033] Add 120 mg (3-cyanopropyl) triethoxysilane (CP-TES), 387.2 mg hydroxylamine (AO) and 275 mg Na 2 CO 3 , heated under reflux at 70°C for 12 hours, and purified by Soxhlet extraction to obtain an amidoximated organosilane functional reagent ((3-amidoximopropyl)triethoxysilane), the reaction formula is as follows:

[0034]

[0035] (2) Preparation of amidoxime mesoporous silica microsphere adsorbent (according to AOES / Na 2 SiO 3 Mass ratio 20wt.% implementation)

[0036] Take 60mL of absolute ethanol, 80mL of deionized water, 30mL of acetic acid solution (25wt.%) and 2.0mL of P123 and place them in a container and stir quickly; while stirring, add 50mL of sodium silicate solution (containing 10.0g of silicon NaOH) and 2.0g AOES were thoroughly mixed to obtain a mix...

Embodiment 3

[0039] A preparation method of amidoxime mesoporous silica microsphere adsorbent, the specific steps are as follows:

[0040] (1) Synthesis of amidoximated organosilane functionalization reagent (AOES)

[0041]Add 120 mg (3-cyanopropyl) triethoxysilane (CP-TES), 387.2 mg hydroxylamine (AO) and 275 mg Na 2 CO 3 , heated under reflux at 70°C for 12 hours, and purified by Soxhlet extraction to obtain amidoximated organosilane functionalization reagent ((3-amidoximopropyl)triethoxysilane), the reaction formula is as follows:

[0042]

[0043] (2) Preparation of amidoxime mesoporous silica microsphere adsorbent (according to AOES / Na 2 SiO 3 Mass ratio 30wt.% implementation)

[0044] Take 60mL of absolute ethanol, 80mL of deionized water, 30mL of acetic acid solution (25wt.%) and 2.0mL of P123 and place them in a container for rapid stirring and mixing. While stirring, add 50mL of sodium silicate solution (containing 10.0g of silicon NaOH) and 3.0g AOES were thoroughly mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com