Seed crystal for aluminium nitride (ALN) crystal growth

A technology of crystal growth and seed crystal, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of high impurity content of AlN crystals, difficult to obtain large-sized AlN crystals, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

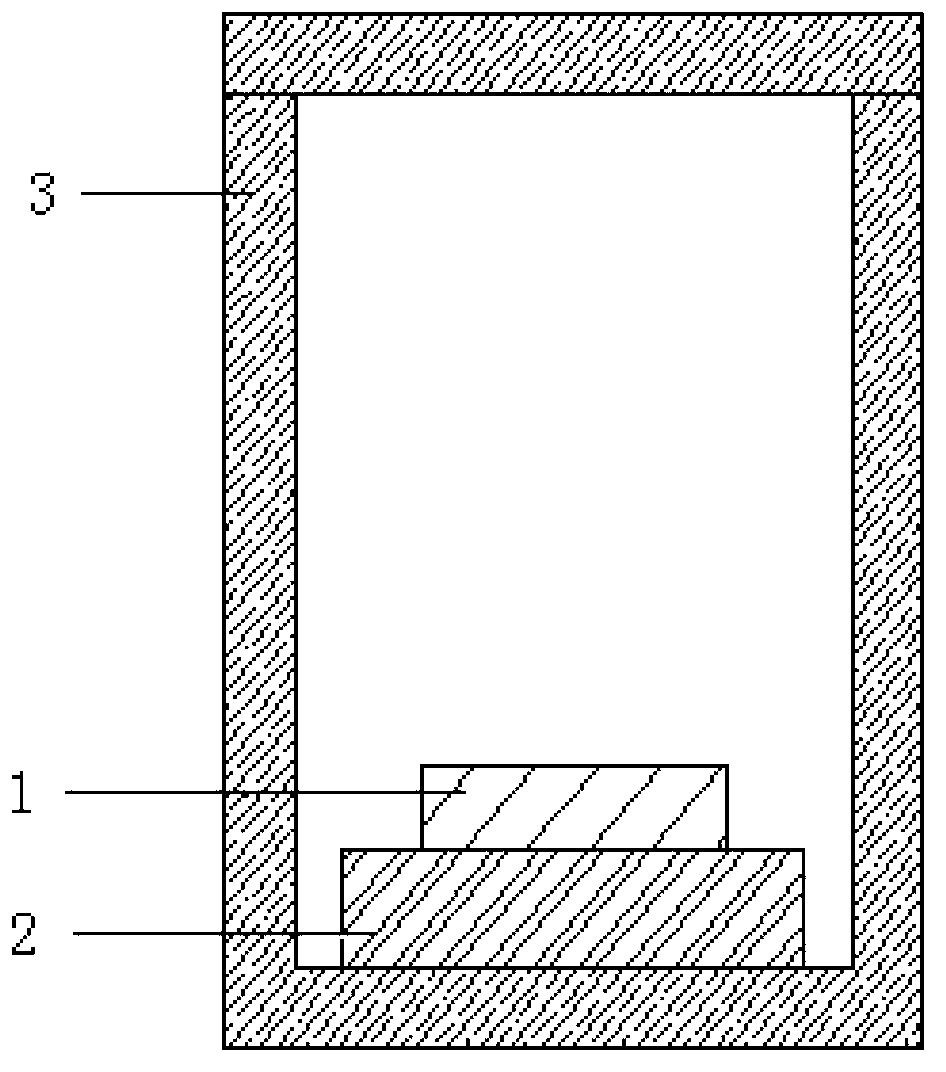

[0038] Specific Embodiment 1: The seed crystal used for AlN crystal growth in this embodiment is an AlN ceramic sheet after annealing process. The diameter of the AlN ceramic sheet is 1~4 inches, the thickness is 0.3~5mm, and the surface roughness Ra≤15nm .

specific Embodiment approach 2

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the annealing process is implemented through the following steps:

[0040] 1. After heating and corroding the AlN ceramic sheet in strong acid or strong alkali, clean the surface of the AlN ceramic sheet with alcohol or acetone, and then dry it with nitrogen to obtain the cleaned AlN ceramic sheet;

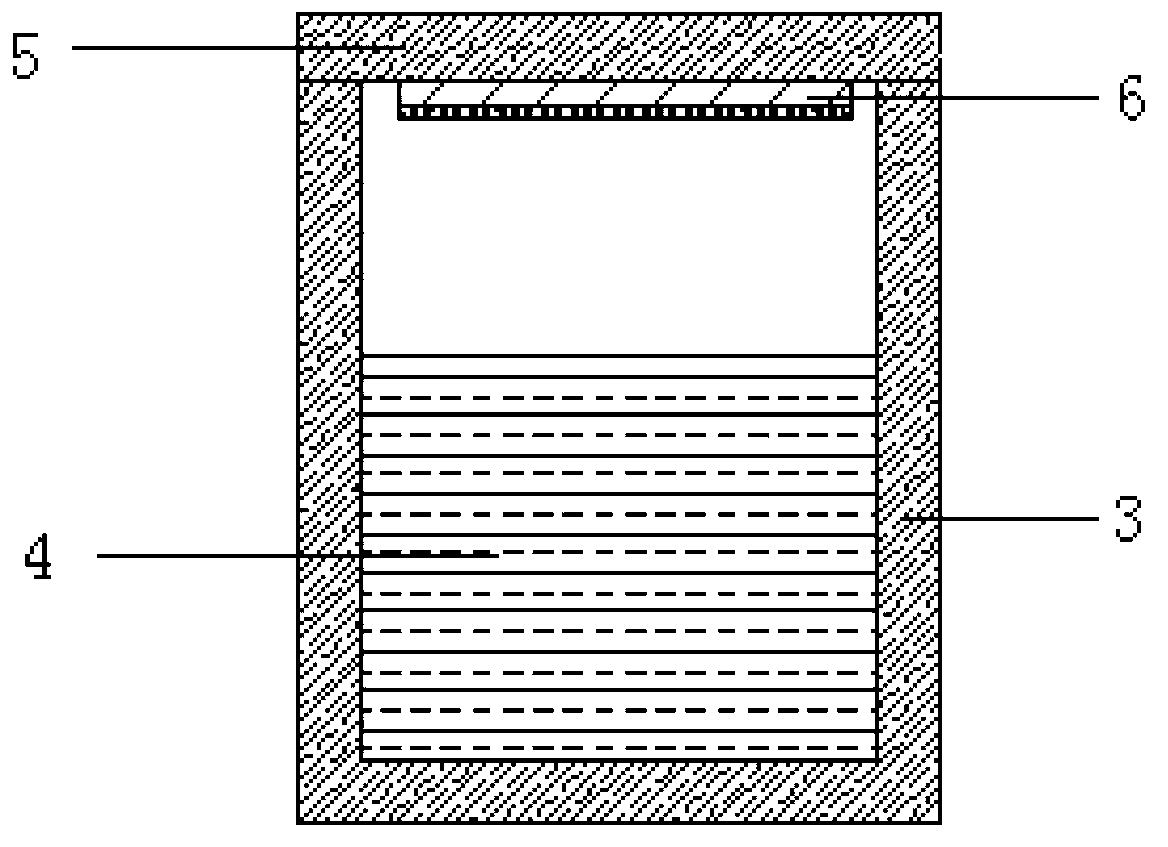

[0041] 2. Put the cleaned AlN ceramic sheet obtained in step 1 on the TaC sheet and put it into the TaC crucible, put the TaC crucible into the high-temperature annealing equipment, and evacuate to 5×10 -4 ~6×10 -4 Pa, into 0.6~1atm nitrogen or argon, then heated to 400~600°C at a heating rate of 10~15°C / min, and then heated to 1800 at a heating rate of 5~10°C / min after holding for 0.5~1 hour ~2100°C, keep warm for 3~8 hours, and then cool down to room temperature at a rate of less than 5°C / min to obtain seed crystals for AlN crystal growth;

[0042] Wherein the step one de...

specific Embodiment approach 3

[0045] Specific Embodiment Three: The seed crystal used for AlN crystal growth in this embodiment is an AlN ceramic sheet that has been annealed and then polished. The diameter of the AlN ceramic sheet is 1 to 4 inches, the thickness is 0.3 to 5 mm, and the surface is rough. Degree Ra≤6nm.

[0046] In this embodiment, the AlN ceramic sheet after the high-temperature annealing process is polished, and the AlN ceramic seed crystal after polishing is nucleated on the surface of the AlN crystal, and the grain size is more uniform, there is no abnormally grown grain, and more It is beneficial to improve the growth quality of AlN crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com