Spontaneous nucleation growth method for thallium bromide single-crystal

A thallium bromide single crystal technology, applied in the field of thallium bromide single crystal growth, can solve problems such as expensive equipment, affecting crystal quality, lattice deformation, etc., to reduce thermal stress, simplify process, and save mechanical transmission The effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

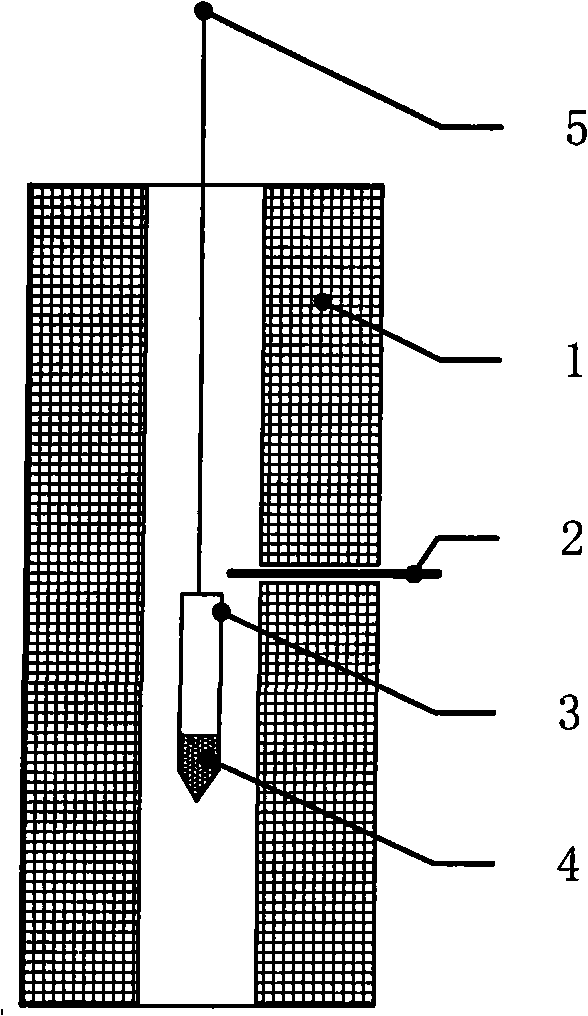

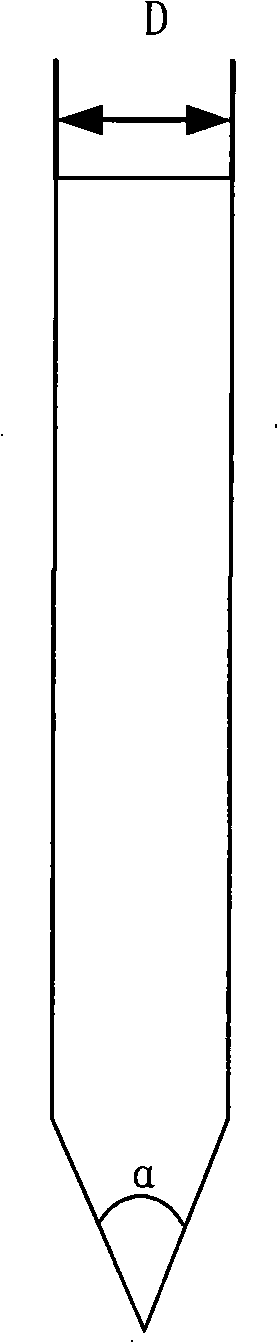

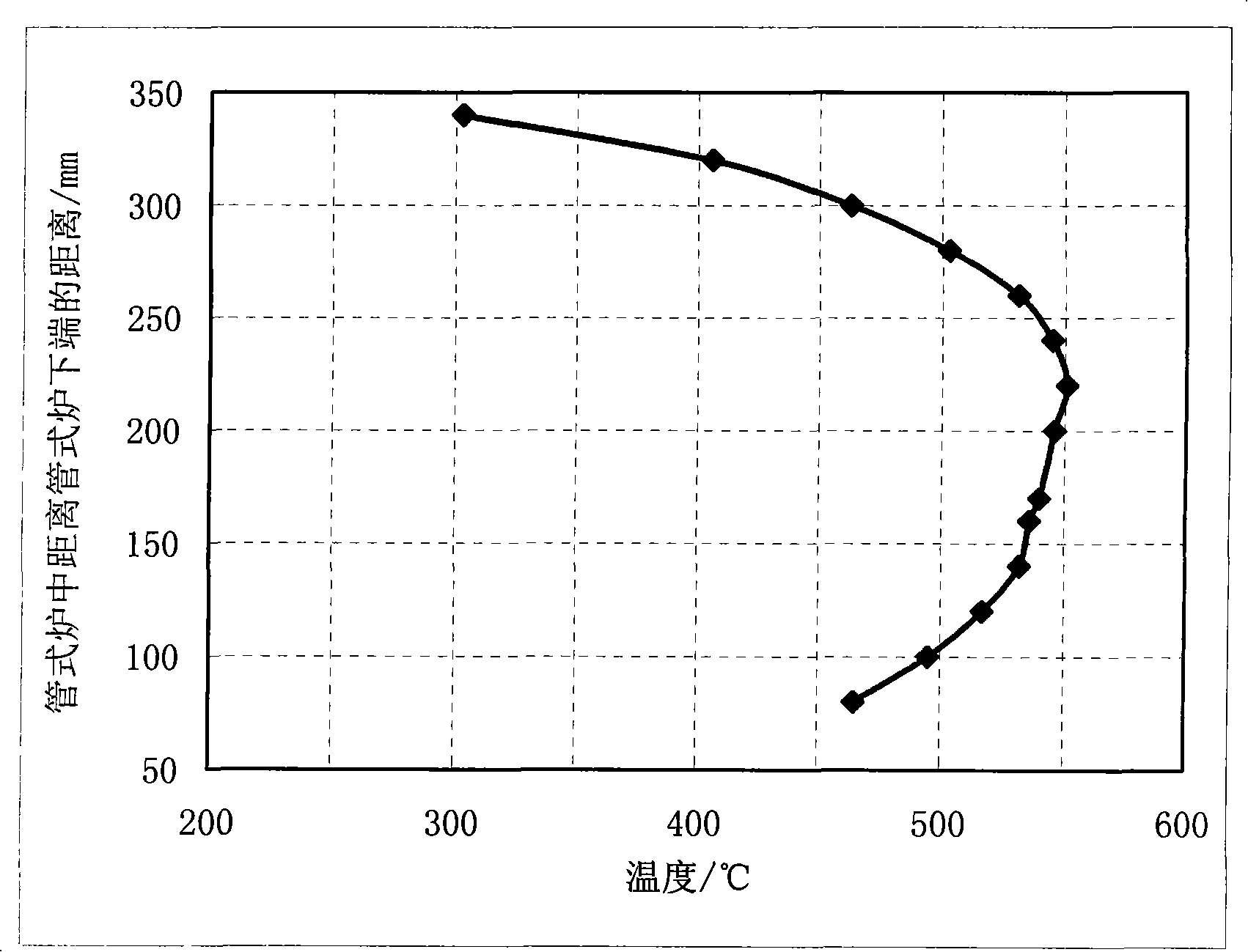

[0027] Put about 5 g of thallium bromide raw material into a quartz ampoule, vacuumize and seal the quartz ampoule. The dimensions of the quartz ampoule are as follows: wall thickness 1 mm, overall length 120 mm, upper cylindrical inner diameter 8 mm, lower conical part taper 28°. Fix the quartz ampoule in the vertical tube furnace with copper wire, so that the conical portion of the quartz ampoule is 90mm away from the lower end of the vertical tube furnace. Raise the temperature from room temperature to 500°C at a rate of 250°C / h, and keep the temperature for 15 hours. Depend on Figure 4 It can be seen that the lowest temperature at the position where the quartz ampoule is located at this time is 476°C, and the axial temperature gradient in the region from 80mm to 130mm upward from the lower end of the vertical tube furnace satisfies 1.0-1.5°C / mm. Depend on Figure 5 It can be seen that as the temperature of the vertical tube furnace decreases, the position of the 460°C ...

Embodiment 2

[0029]Put about 6 g of thallium bromide raw material into a quartz ampoule, vacuumize and seal the quartz ampoule. The dimensions of the quartz ampoule are as follows: wall thickness 1 mm, overall length 120 mm, upper cylindrical inner diameter 10 mm, lower conical part taper 19°. The quartz ampoule is fixed in the vertical tube furnace by steel wire, so that the bottom of the quartz ampoule is 80mm away from the lower end of the vertical tube furnace. Raise the temperature from room temperature to 520°C at a rate of 250°C / h, and keep it warm for 5 hours. image 3 It can be seen that the lowest temperature at the position of the quartz ampoule is 475°C at this time, and the axial temperature gradient in the area from 80mm to 130mm from the lower end of the vertical tube furnace satisfies 1.0-1.5°C / mm, and by Figure 5 It can be seen that as the temperature of the vertical tube furnace decreases, the position of the 460°C isotherm moves upward. Then the temperature was lowere...

Embodiment 3

[0031] Put about 10 g of thallium bromide raw material into a quartz ampoule, vacuumize and seal the quartz ampoule. The dimensions of the quartz ampoule are as follows: wall thickness 1 mm, overall length 120 mm, upper cylindrical inner diameter 15 mm, lower conical part taper 35°. Fix the quartz ampoule in the vertical tube furnace with nickel wire, so that the bottom of the quartz ampoule is 80 mm from the lower end of the vertical tube furnace. With a heating rate of 300°C / h, the temperature of the thermocouple in the vertical tube furnace is raised from room temperature to 520°C, and the temperature is kept for 10 hours. image 3 It can be seen that the lowest temperature at the position where the quartz ampoule is located at this time is 475°C, and the axial temperature gradient in the region from 80mm to 130mm from the lower end of the vertical tube furnace satisfies 1.0-1.5°C / mm. Then the temperature was lowered to 450° C. at a cooling rate of 5° C. / h to complete the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com