Method for preventing monocrystal blades from having mixed crystal defects

A single crystal blade and miscellaneous crystal technology is applied in the field of preventing miscellaneous crystal defects in single crystal blades, which can solve the problems of forming miscellaneous crystals, difficulty in producing single crystal castings, new grain growth, etc., so as to improve the yield and suppress miscellaneous crystals. Defects, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

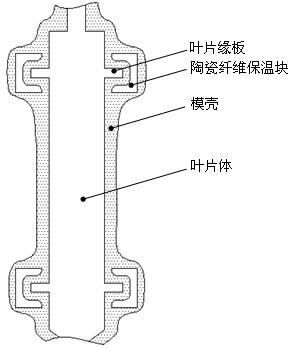

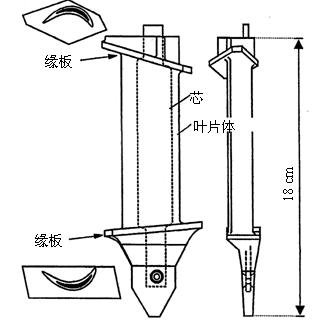

[0015] Apply the present invention to a single crystal blade ( image 3 ), the blade material is superalloy CMSX-4, and the raw material of the ceramic fiber insulation block is the SILCASTACK-160 ceramic fiber module produced by SILCA Service- und Vertriebsgesellschaft fuer Daemmstoffe mbH, with a temperature resistance of 1600°C and a thermal conductivity of 0.31 W at 1250°C / (mK). In the preparation process of the aluminum oxide formwork for the blade, the first seven layers of the single crystal blade formwork are prepared according to the conventional investment casting process; the U-shaped inner cavity of the insulation block is prefabricated according to the outer shape of the formwork at the edge plate of the blade at this time, and made The insulation block can cover all positions of the edge plate formwork, and the thickness of the insulation block is 3-5mm; then use the shell slurry as the adhesive to bond the insulation block to the outside of the edge plate formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com