Seeding mold for growing silicon crystals by using orientated solidification method and crystal growing method

A technology for growing silicon crystals and directional solidification, applied in crystal growth, self-solidification, single crystal growth, etc., to achieve the effects of avoiding spontaneous nucleation, low cost, and solving the problem of seed crystal placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

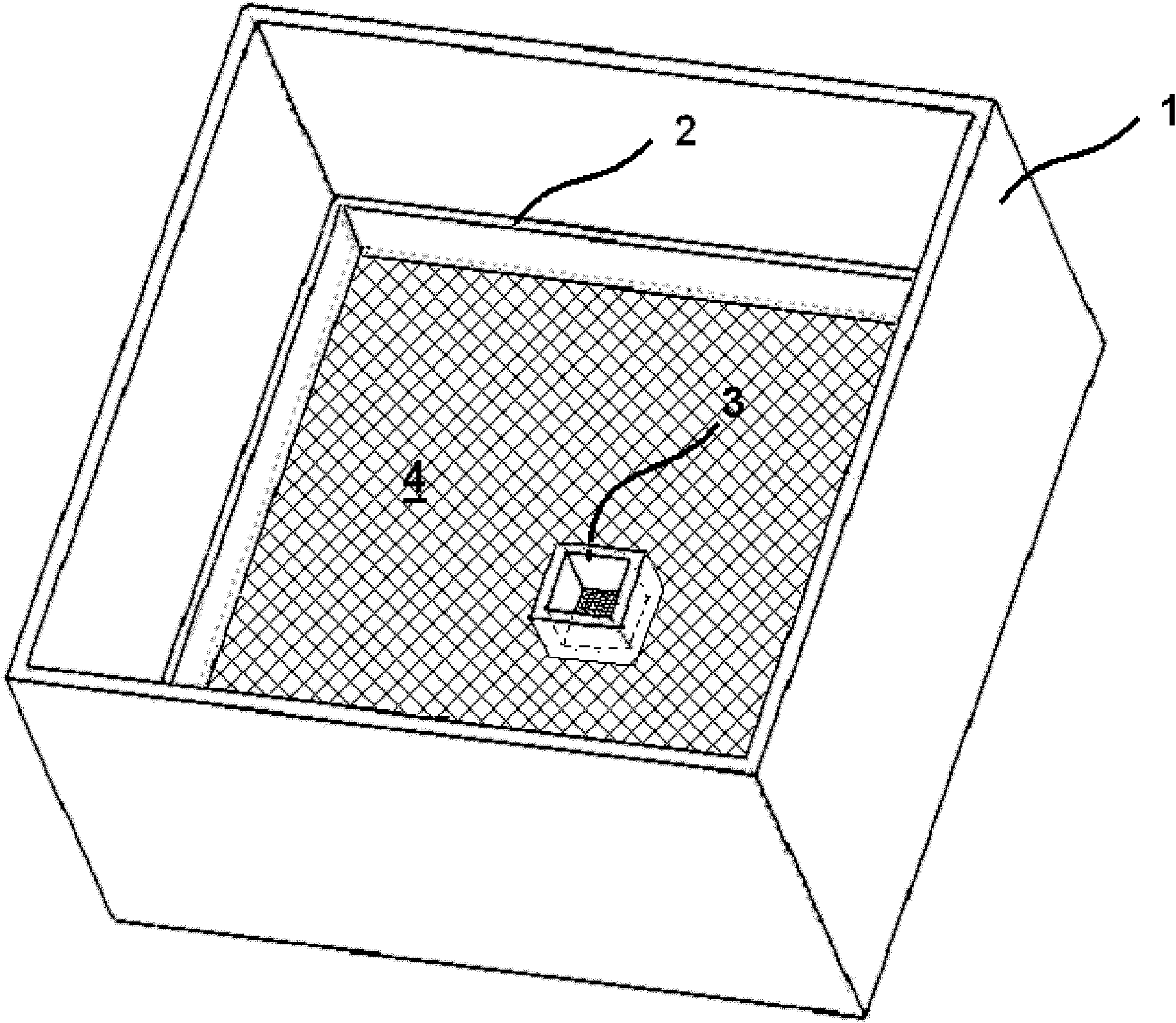

[0038] Such as image 3 and Figure 4 A kind of seeding mold 2 shown is processed by graphite material and placed in the bottom of prior art quartz crucible 1, including seed crystal container 3 and spacer liquid container 4, there is a square cylinder in the middle of seed crystal container 3 The first cavity is used to place the seed crystal 5, and the cross-sectional area of the first cavity is 10000mm 2 , the height is 30mm, and the cross-sectional shape is a square; the spacer container 4 is formed by a cavity connected to the seed crystal container 3, and the cavity is surrounded by a graphite wall. Correspondingly, the bottom shape of the insulating liquid container 4 is adapted to the bottom shape of the quartz crucible 1 , so that the (liquid) insulating substance 8 placed in the insulating liquid container 4 can be separated from the bottom wall of the quartz crucible 1 . The upper part of the insulating liquid container 4 is open, and communicates with the inner...

Embodiment 2

[0045] Such as Figure 6 As shown, adopt the same method as that of Example 1, the difference is that in order to seed the crystal and better control the temperature gradient, the first cavity of the seed crystal container 3 has a section of diameter shrinkage near its top to form a long 10mm cavity. The necking section, the necking section itself is equal in diameter, but because the necking section has a gradually shrinking diameter, when the seed crystal grows through the narrow channel of the necking section, it can better eliminate the bit growth from the seed crystal. wrong.

[0046] In addition, a cavity is provided at the bottom of the seed crystal container 3, so that the temperature difference between the temperature at the position of the seed crystal 5 and the temperature around the quartz crucible 1 is larger, so that the temperature at the seed crystal 5 can be lowered when the silicon melt is kept overheated. Right around the melting point.

[0047] A further ...

example example 3

[0049] In the same manner as in Example 1, the difference is that the spacer 8 used is 6N high-purity germanium (Ge, with a purity of 99.9999%) and 5N high-purity lead (Pb, with a purity of 99.999%). The mass percentage is 1: 1 mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com