Particle size regulation method of glycine periodic crystallization process

A technology of glycine and control method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve the effect of low operating cost, simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

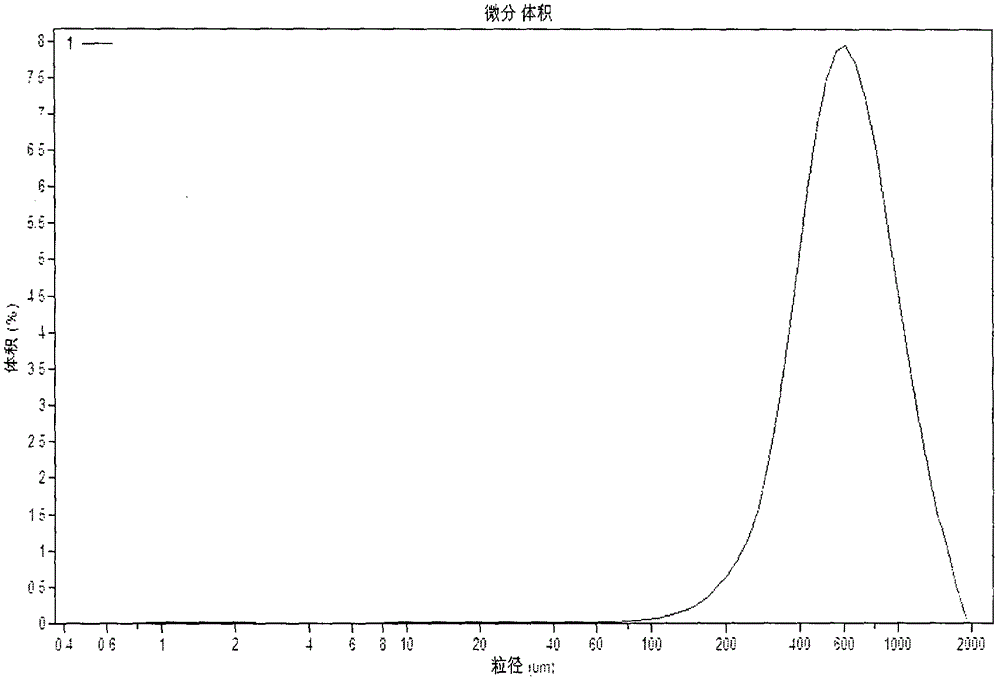

Embodiment 1

[0025] Dissolve 30.0g of glycine in 60.0g of an aqueous solution at a temperature of 72°C, then cool the solution to 60°C, keep the temperature constant until nucleation erupts, and start to cool down at a cooling rate of 0.5°C / min after crystal growth for 30 minutes, until it drops to 15°C , after 30 minutes of crystal growth, vacuum filtration and drying obtained glycine crystals with an average particle size of 671.5 μm.

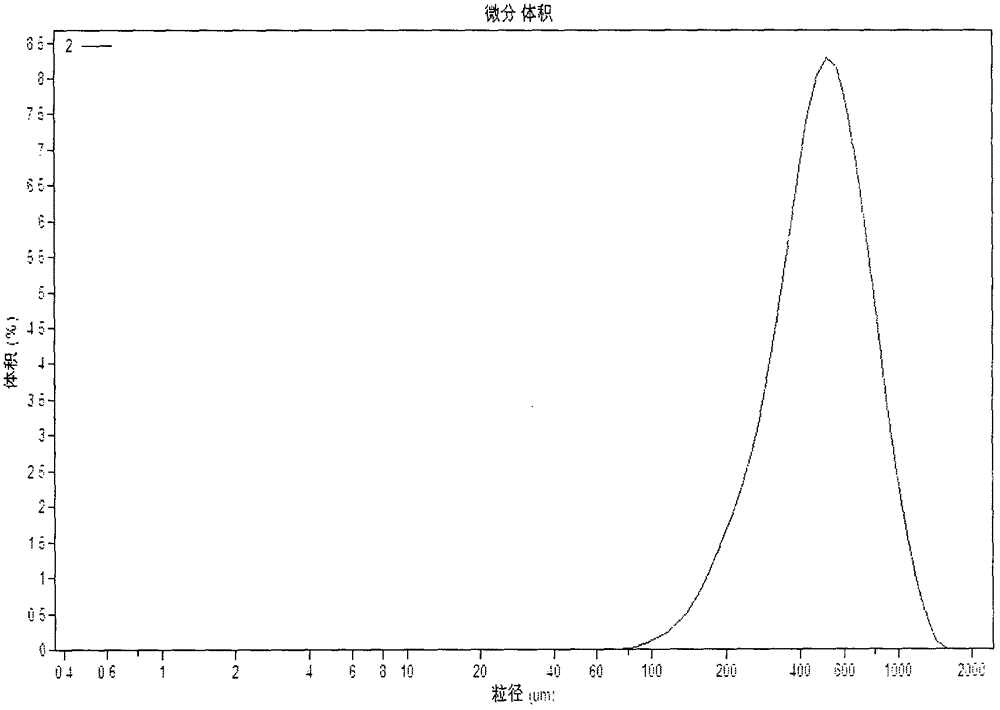

Embodiment 2

[0027] Dissolve 30.0g of glycine in 60.0g of aqueous solution at a temperature of 72°C, then lower the temperature of the solution to 54°C, keep the temperature constant until nucleation occurs, and start to cool down at a cooling rate of 0.5°C / min after growing the crystal for 30 minutes until it drops to 15°C , after 30 minutes of crystal growth, vacuum filtration and drying obtained glycine crystals with a particle size of 521.9 μm.

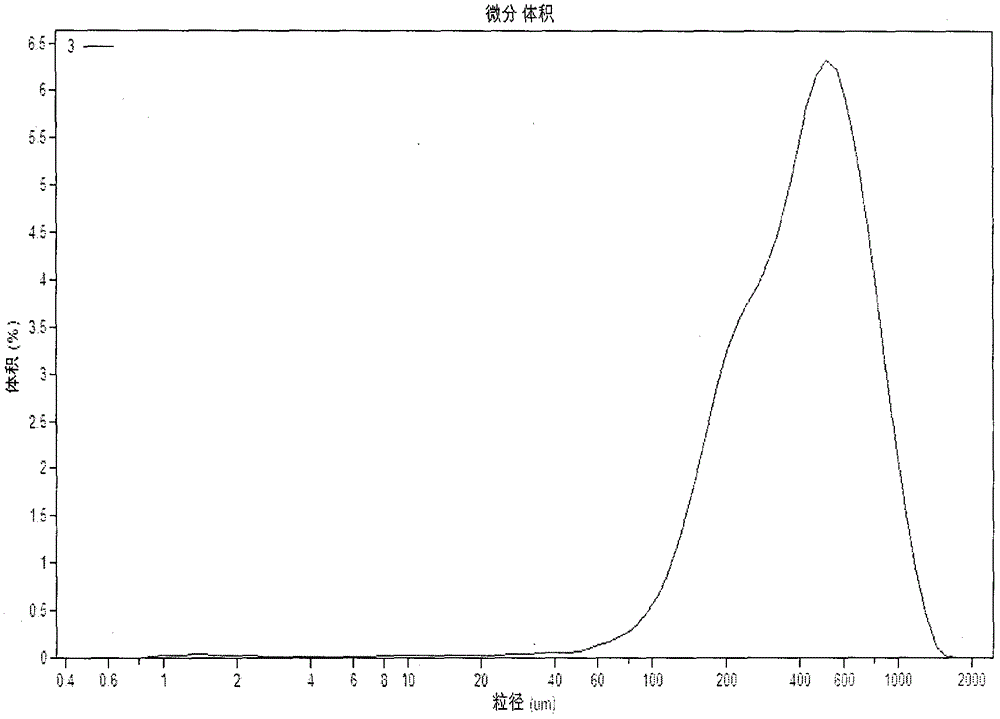

Embodiment 3

[0029] Dissolve 21g of glycine in 60g of aqueous solution at a temperature of 50°C, then lower the temperature of the solution to 25°C, keep the temperature constant until nucleation erupts, and start cooling at a cooling rate of 0.5°C / min after growing the crystal for 30 minutes until it drops to 10°C. After 30 minutes of crystallization, vacuum filtration and drying obtained glycine crystals with a particle size of 462.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com