Preparing method of large diameter yttrium barium copper oxide superconducting single domain blocks

A yttrium-barium-copper-oxide, large-diameter technology, which is applied in the field of preparation of large-diameter yttrium-barium-copper-oxide superconducting single-domain bulk materials, can solve complex preparation processes, high requirements for seed crystal orientation and positioning consistency, and non-seed crystal spontaneous generation. Nucleation and other problems, to achieve the effect of simplifying the preparation process and avoiding the problem of seed crystal orientation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

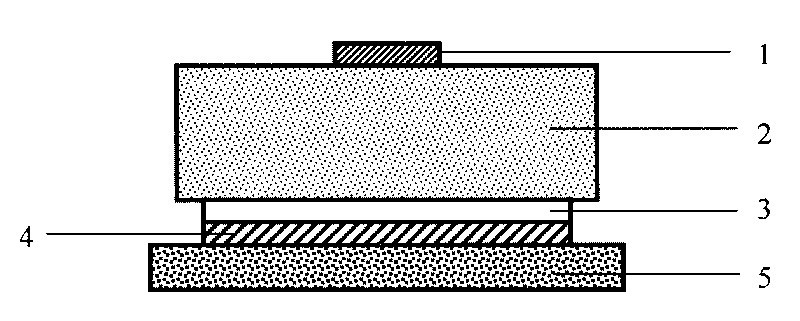

[0028] (1) Take 320 grams of precursor mixed powder (Y123+30%molY211+0.5%wt CeO2), put it into a mold with a diameter of 65mm, and perform uniaxial compression molding with a compression molding pressure of 20MPa. Pressed into a diameter of 65mm, a preform body (2) with a thickness of about 23mm.

[0029] (2) Take 35 grams of mixed powder for the transition layer gasket, and uniaxially press-mold it into a transition layer gasket (3) with a diameter of 60 mm and a thickness of 4 mm.

[0030] (3) Set the size to 14×14×3mm 3 The SmBCO seed crystal (1) is placed on the upper surface of the yttrium barium copper oxide preform body, the body is placed on the transition layer gasket, and the MgO single wafer (4) and Al 2 o 3 Ceramic plates (5). The overall structure of the sintered body before entering the furnace is shown in the attached figure 1 .

[0031] (4) After the green body is put into the furnace, the temperature is raised to 1047°C, and the temperature is rapidly low...

Embodiment 2

[0035] (1) Take 420 grams of precursor mixed powder (Y123+30%molY211+0.5%wt CeO2), put it into a mold with a diameter of 85mm, and perform uniaxial compression molding with a compression molding pressure of 30MPa. Pressed into a diameter of 85mm, a preform body (2) with a thickness of about 18mm.

[0036] (2) Take 50 grams of mixed powder for the transition layer gasket, and uniaxially press mold it into a transition layer gasket (3) with a diameter of 80 mm and a thickness of 3 mm.

[0037] (3) Set the size to 15×15×3mm 3 The SmBCO seed crystal (1) is placed on the upper surface of the yttrium barium copper oxide preform body, the body is placed on the transition layer gasket, and the MgO single wafer (4) and Al 2 o 3 Ceramic plates (5). The overall structure of the sintered body before entering the furnace is shown in the attached figure 1 .

[0038](4) After the green body is put into the furnace, the temperature is raised to 1050°C, and the temperature is rapidly cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com