Metal-ceramic alloy powder block for build-up welding

A technology of cermet and alloy powder, which is applied in the field of surfacing welding cermet alloy powder block and its preparation, can solve the problems not related to the fatigue performance of surfacing metal, and achieve easy automatic surfacing, strong and sufficient metallurgical reaction, and high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

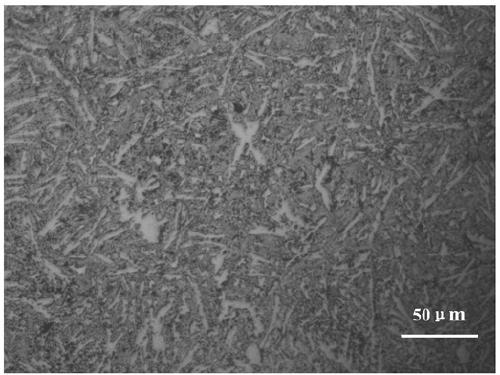

Embodiment 1

[0089] The formula of the cermet alloy powder is calculated in parts by mass, the binder is 15, the plasticizer is 8, the electrolytic metal manganese is 4, the 45# ferrosilicon is 2, the titanium iron is 4, the metal chromium is 10, the boron iron is 38, and the graphite is 3. , 6 iron vanadium, molybdenum powder 50, metal nickel powder 3, iron powder 8, nanometer titanium carbide powder 4, yttrium oxide powder 4. The particle size of nano titanium carbide powder is more than 99% smaller than 40 nanometers, and the particle size of other powders is 75 microns to 180 microns (that is, the particle size is -80 mesh to +200 mesh).

[0090] The binder is sodium water glass with a modulus of 3.0 and a degree of Baume of 50. The plasticizer is titanium dioxide.

[0091] (1) Passivation of iron alloys 45# ferrosilicon, metal manganese, and metal chromium were placed in heat-resistant steel plates respectively, with a stacking thickness of 30 mm, and stirred for 3 times during roast...

Embodiment 2

[0098] The formula of the cermet alloy powder is calculated in parts by mass, the binder is 10, the plasticizer is 2, the electrolytic metal manganese is 8, the 45# ferrosilicon is 6, the titanium iron is 2, the metal chromium is 5, the boron iron is 20, and the iron vanadium is 20. 2. Molybdenum powder 32, metal nickel powder 6, iron powder 2, nano-titanium carbide powder 2, yttrium oxide powder 2. The particle size of nano titanium carbide powder is more than 99% smaller than 40 nanometers, and the particle size of other powders is 75 microns to 180 microns (that is, the particle size is -80 mesh to +200 mesh).

[0099] The binder is potassium-sodium mixed water glass, the mass fraction of potassium is 2, the mass fraction of sodium is 1, the modulus is 2.8, and the Baume degree is 39. The plasticizer is white clay.

[0100] (1) Passivation of iron alloys 45# ferrosilicon, electrolytic metal manganese, and metal chromium were placed in heat-resistant steel trays with a stac...

Embodiment 3

[0107] The formula of the cermet alloy powder is calculated in parts by mass, and the binder is 5, electrolytic metal manganese 6, 45# ferrosilicon 5, titanium ferrous 3, metal chrome 8, ferroboron 30, ferrovanadium 5, molybdenum powder 42, Metal nickel powder 4, iron powder 6, nano-titanium carbide powder 3, yttrium oxide powder 3. The particle size of nano titanium carbide powder is more than 99% smaller than 40 nanometers, and the particle size of other powders is 75 microns to 180 microns (that is, the particle size is -80 mesh to +200 mesh).

[0108] The binder is sodium water glass with a modulus of 2.9 and a Baumé degree of 45.

[0109] (1) Passivation of iron alloys 45# ferrosilicon, electrolytic metal manganese, and metal chromium were placed in heat-resistant steel plates respectively, with a stacking thickness of 35mm, and stirred 4 times during roasting. The technical parameters of roasting are: 45# ferrosilicon at 750°C, holding for 1 hour, and cooling with the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com