Polycrystalline synthesis method and single-crystal growth method of gallium selenide

A synthesis method and a growth method technology are applied in the fields of polycrystalline synthesis and single crystal growth of gallium selenide, which can solve the problems of non-stoichiometric ratio and low yield, ineffective crystal nucleus and uncertain growth direction of single crystal, etc. Yield-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

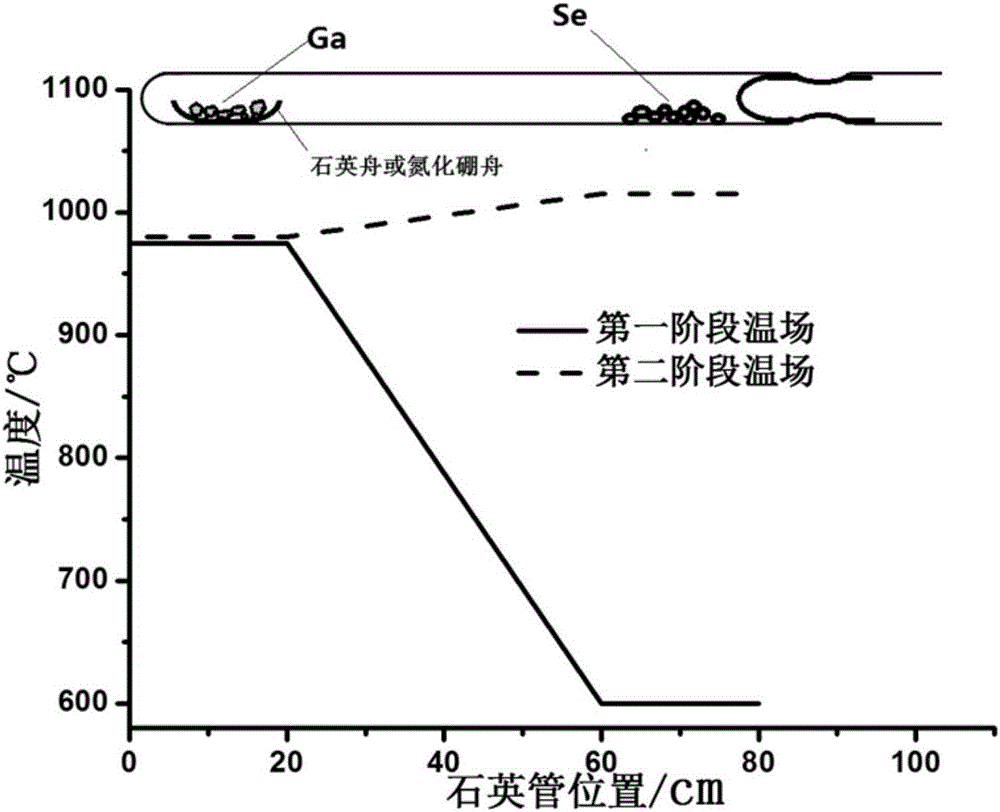

[0022] Specific embodiment one: the polycrystalline synthesis method of GaSe of the present embodiment is carried out according to the following steps:

[0023] 1. Soak the quartz tube and the quartz boat or boron nitride boat used for holding the material with aqua regia, then wash with ultrapure water and dry; weigh the elemental raw material Ga according to the molar ratio Ga:Se=1:(1+n) and Se, where n=PV / RT, P are 1 atmospheric pressure, V is the cylinder void volume in the quartz tube, T is (600+273) K, and R is the gas constant;

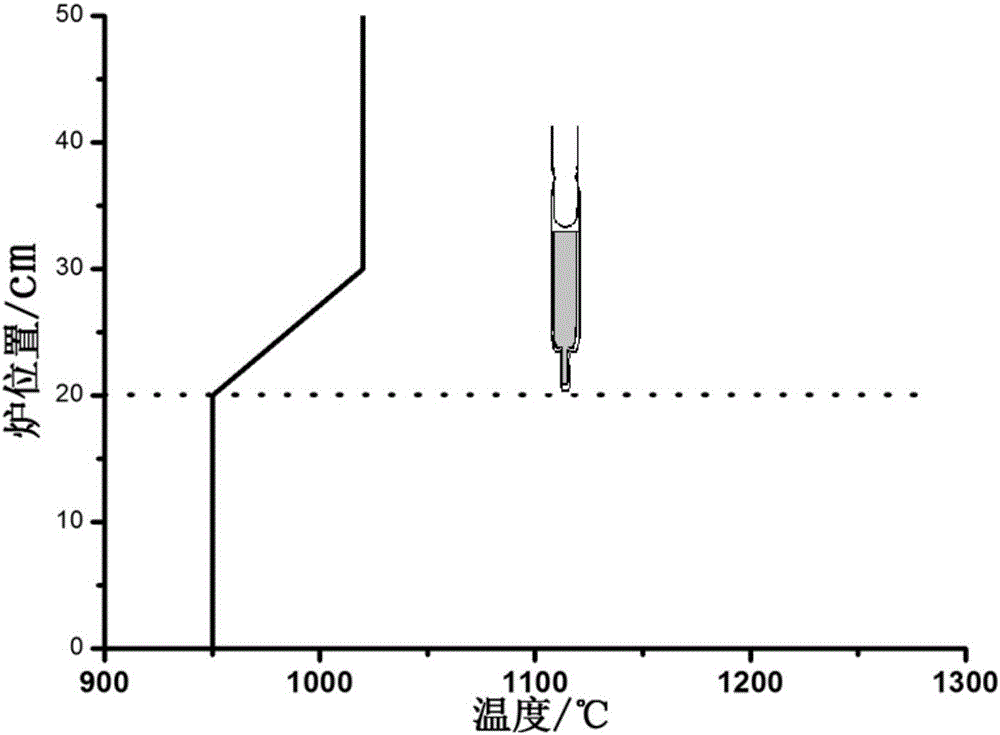

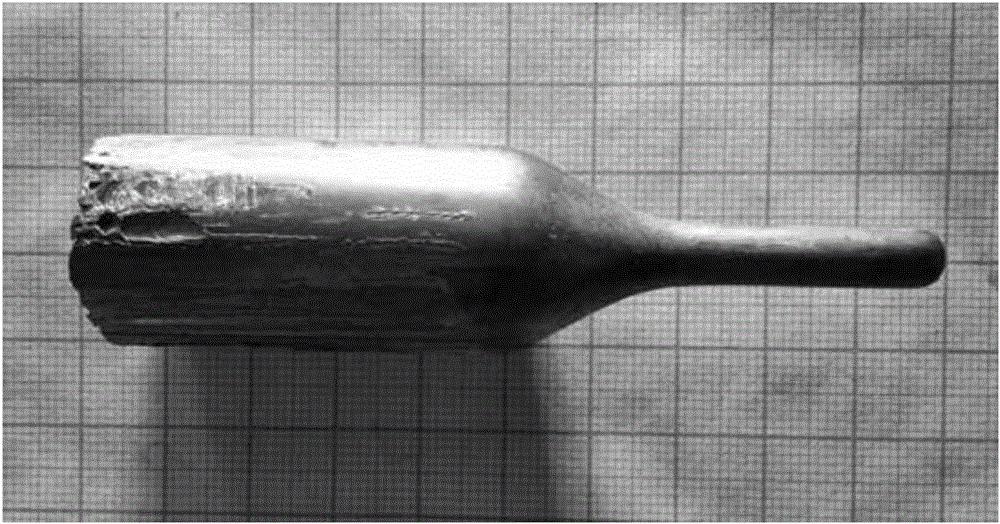

[0024] 2. Place Ga in a small boat, place the small boat containing Ga at the closed end of the quartz tube, and place Se directly at the other end of the quartz tube; vacuumize the quartz tube, and then seal the quartz tube with a hydrogen-oxygen flame. Then put it into a horizontal dual temperature zone tubular resistance furnace, the boat filled with Ga is located in the high temperature zone, Se is located in the low temperature zone, and t...

specific Embodiment approach 2

[0026] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the quartz tube and the quartz boat or boron nitride (PBN) boat used in step one are soaked in aqua regia for 6-8 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, the quartz tube is evacuated to 10 -4 Pa~10 -6 Pa. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com