Graphene single crystal and growth method thereof

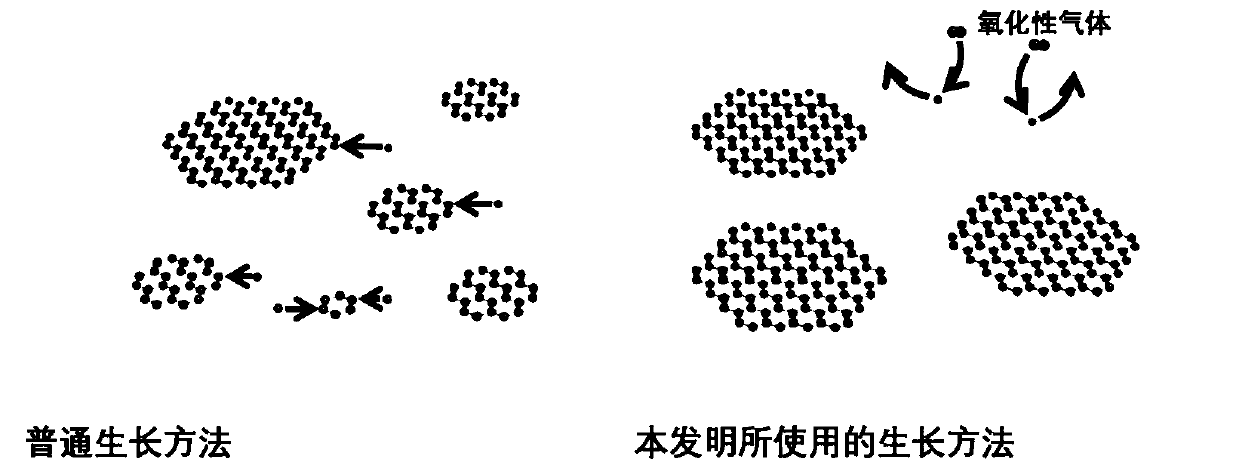

A growth method and graphene technology, applied in the field of materials, can solve the problems of uneven size of graphene domains, affecting the properties of graphene, etc., and achieve the effects of improving electrical conductivity and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Cut ordinary industrial copper foil (purity 99.8%, thickness 50μm) into a rectangular foil with a length of 30cm and a width of 10cm, use a nitrogen gun to blow off the dust and particles that may exist on the surface of the copper foil, and place it horizontally on a flat graphite carrier superior.

[0033] 2) Put the above-mentioned graphite carrier into the central constant temperature zone of a 6-inch three-temperature zone tube furnace (produced by Tianjin Zhonghuan Company, the length of each temperature zone is 35cm). The temperature was raised to 1020° C. in an air atmosphere.

[0034] 3) After the temperature rises to 1020°C, change the gas to 500 sccm argon-oxygen mixed gas (oxygen ratio is 0.04%), anneal the copper foil in this atmosphere for 30 minutes, and fully remove the organic pollution such as oil stains that may exist on the surface of the industrial copper foil , thereby reducing the nucleation density of subsequent graphene.

[0035] 4) Keeping...

Embodiment 2

[0043] 1) Cut ordinary industrial copper foil (purity 99.8%, thickness 50μm) into a rectangular foil with a length of 30cm and a width of 10cm, use a nitrogen gun to blow off the dust and particles that may exist on the surface of the copper foil, and place it horizontally on a flat graphite carrier superior.

[0044] 2) Put the above-mentioned graphite carrier into the central constant temperature zone of a 6-inch three-temperature zone tube furnace (produced by Tianjin Zhonghuan Company, the length of each temperature zone is 35cm). The temperature was raised to 1020° C. in an air atmosphere.

[0045] 3) After the temperature rises to 1020°C, change the gas to 500 sccm argon-oxygen mixed gas (oxygen ratio is 0.04%), anneal the copper foil in this atmosphere for 30 minutes, and fully remove the organic pollution such as oil stains that may exist on the surface of the industrial copper foil , thereby reducing the nucleation density of subsequent graphene.

[0046]4) Keeping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com