Process for producing YBCO superconducting thin film target material

A technology of superconducting thin film and target material, which is applied in the field of YBCO superconducting thin film target material preparation, can solve the problems of large internal stress of the sheet, high preparation cost, high cost of rubber sheathing, etc. Excellent superconductivity and low sheath cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

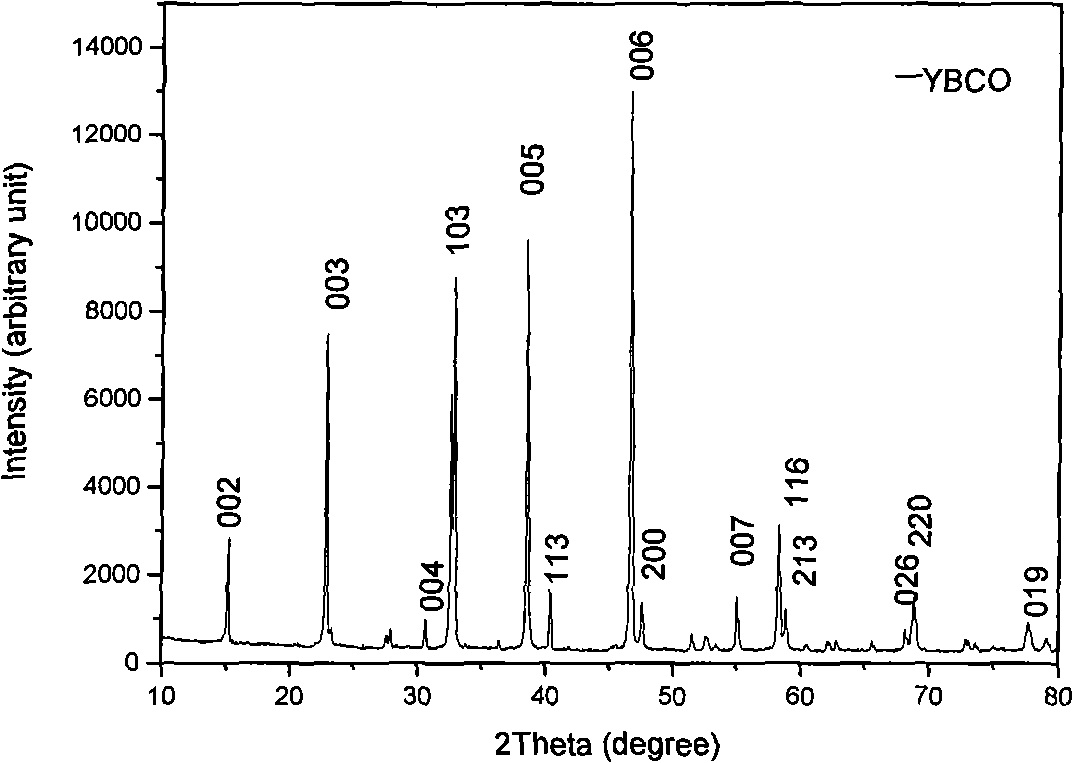

Image

Examples

Embodiment 1

[0024] A specific embodiment of the present invention is a method for preparing a YBCO superconducting thin film target, which is as follows:

[0025] A, Preparation of YBCO superconducting phase powder

[0026] According to the stoichiometric ratio of Y (yttrium): Ba (barium): Cu (copper) = 1:2:3, weigh Y respectively 2 o 3 (yttrium oxide), BaCO 3 (barium carbonate), CuO (copper oxide), and then Y 2 o 3 Mix and grind with CuO, then add BaCO 3 Mix and grind into powder, sinter the powder at 920°C for 20 hours, and grind the sintered product into powder; repeat the above sintering and grinding twice to obtain superconducting phase powder. In this example, a total of 3 sinterings were performed.

[0027] B. Tablet

[0028] The powder prepared in step A is evenly placed in the mould, and pressed into tablets with a pressure of 20Mpa on a press; guide sheet;

[0029] C. Sintering of sheets

[0030] Sintering the superconducting sheet obtained in step B in a box furnace f...

Embodiment 2

[0035] A kind of preparation method of YBCO superconducting film target material, its practice is:

[0036] A, Preparation of YBCO superconducting phase powder

[0037] According to the stoichiometric ratio of Y:Ba:Cu=1:2:3, weigh Y respectively 2 o 3 、BaCO 3 , CuO, and then Y 2 o 3 Mix and grind with CuO, then add BaCO 3 Mix and grind into powder, sinter the powder at 960°C for 30 hours, and grind the sintered product into powder; repeat the above sintering and grinding 4 times to obtain superconducting phase powder. A total of 5 sinterings were carried out in this example.

[0038] B. Tablet

[0039] The powder prepared in step A is evenly placed in the mould, and pressed into tablets with a pressure of 30Mpa on a press; guide sheet;

[0040] C. Sintering of sheets

[0041] Sintering the superconducting sheet obtained in step B for 30 hours in a box furnace at a sintering temperature of 960°C;

[0042] D. Oxygen penetration

[0043] The superconducting sheet after ...

Embodiment 3

[0045] A kind of preparation method of YBCO superconducting film target material, its practice is:

[0046] A, Preparation of YBCO superconducting phase powder

[0047] According to the stoichiometric ratio of Y:Ba:Cu=1:2:3, weigh Y respectively 2 o 3 、BaCO 3 , CuO, and then Y 2 o 3 Mix and grind with CuO, then add BaCO 3 Mix and grind into powder, sinter the powder at 940°C for 25 hours, and grind the sintered product into powder; repeat the above sintering and grinding 3 times to obtain superconducting phase powder;

[0048] B. Tablet

[0049] The powder prepared in step A is evenly placed in the mould, and the tablet is pressed with a pressure of 25Mpa on the press; guide sheet;

[0050] C. Sintering of sheets

[0051] Sintering the superconducting sheet obtained in step B in a box furnace for 25 hours at a sintering temperature of 950°C;

[0052] D. Oxygen penetration

[0053] The superconducting sheet sintered in step C is placed in a tube furnace, and subjecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com