Method for manufacturing single crystal grain niobium material for radio frequency superconducting cavity

A technology of radio frequency superconducting cavity and manufacturing method, which is applied in the directions of single crystal growth, single crystal growth, polycrystalline material growth, etc., and can solve the problem that it is difficult to further improve the superconducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

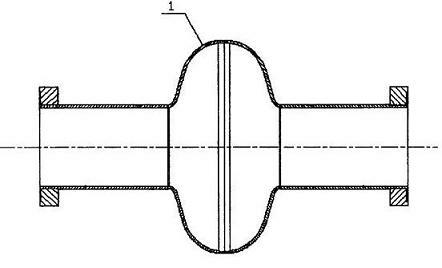

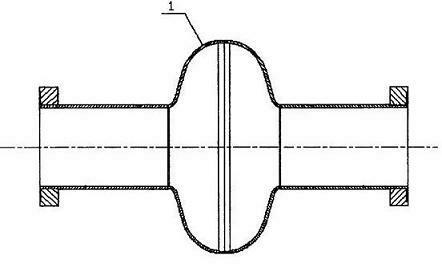

Image

Examples

Embodiment 1

[0027] 1. Cut the single crystal niobium material from the large-grained niobium ingot with a diameter of 150mm and a thickness of 20mm. value above 300);

[0028] 2. The single crystal niobium material is processed into niobium sheets by means of cross rolling, with a processing rate of 4% per pass and a thickness of 3.0mm;

[0029] 3. Machining the single crystal niobium plate into a niobium sheet with a diameter of Ф266mm and a thickness of 2.8mm;

[0030] 4. Chemical polishing: use a mixed acid of hydrofluoric acid, nitric acid, and phosphoric acid (volume ratio 1:1:2) to pickle and polish the single crystal niobium sheet;

[0031] 5. Stress relief annealing: at 10 -4 The heat treatment is carried out under the high vacuum condition of Pa, and the treatment temperature is 700°C, and the processing stress is eliminated, and the single-grain niobium material is obtained.

Embodiment 2

[0033] 1. Cut the single crystal niobium material from the large-grained niobium ingot with a diameter of 200-300mm and a thickness of 25mm. RRR value above 300);

[0034] 2. The single crystal niobium material is processed into niobium sheets by means of cross rolling, with a processing rate of 3% per pass and a thickness of 3.0mm;

[0035] 3. Machining the single crystal niobium plate into a niobium sheet with a diameter of Ф496mm and a thickness of 2.8mm;

[0036] 4. Chemical polishing: use a mixed acid of hydrofluoric acid, nitric acid, and phosphoric acid (volume ratio 1:1:2) to pickle and polish the single crystal niobium sheet;

[0037] Stress relief annealing: at 10 -4 The heat treatment is carried out under the high vacuum condition of Pa, and the treatment temperature is 700°C, and the processing stress is eliminated, and the single-grain niobium material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com