Manufacturing method of GaN field effect transistor

A gallium nitride field and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as rough surface and poor edge morphology, and achieve good uniformity and reliability of withstand voltage high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for manufacturing a GaN field effect transistor, which is used for manufacturing a GaN field effect transistor.

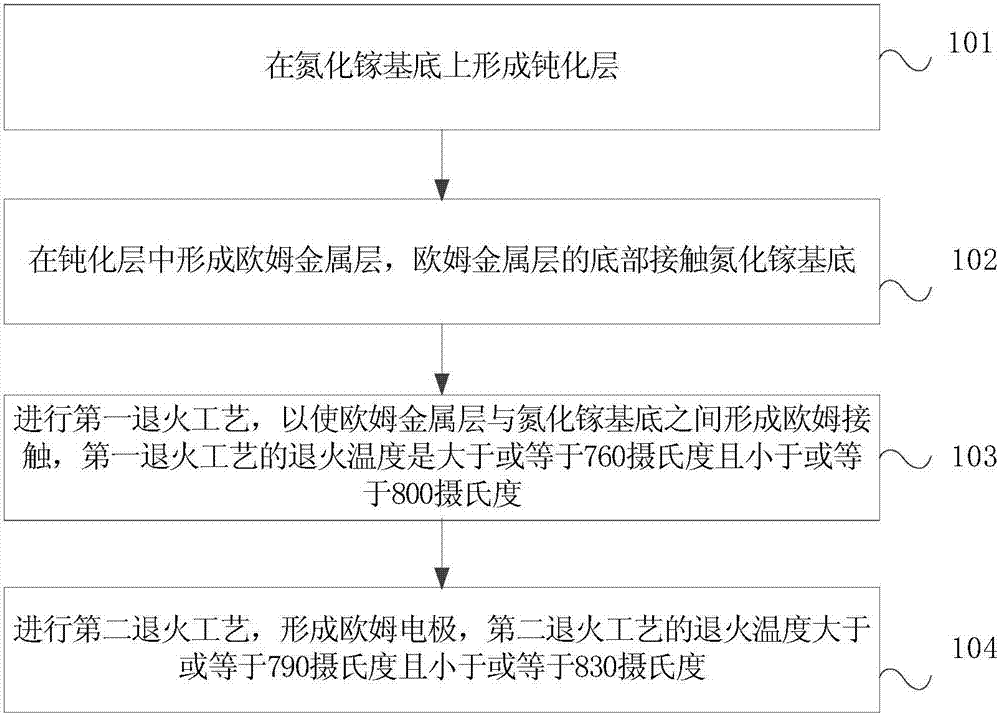

[0034] Such as figure 1 As shown, is a schematic flow chart of the fabrication method of the eGaN field effect transistor according to the present embodiment. The fabrication method of the gallium nitride field effect transistor of this embodiment includes:

[0035] Step 101, forming a passivation layer on a GaN substrate.

[0036] The gallium nitride substrate may be any substrate used for manufacturing gallium nitride field effect transistors in the prior art. In this embodiment, the gallium nitride substrate includes a Si substrate, a GaN layer and an AlGaN layer formed sequentially from bottom to top.

[0037] The passivation layer in this embodiment is used to protect the metal surface from being oxidized, thereby delaying the corrosion rate of the metal and improving the reliability of the semiconductor device. The...

Embodiment 2

[0046] In this embodiment, a further supplementary explanation is given to the fabrication method of the eGaN field effect transistor in the above embodiments. Such as Figures 2A to 2G Shown is a structural schematic diagram of each step in the manufacturing method of the eGaN field effect transistor according to the present embodiment.

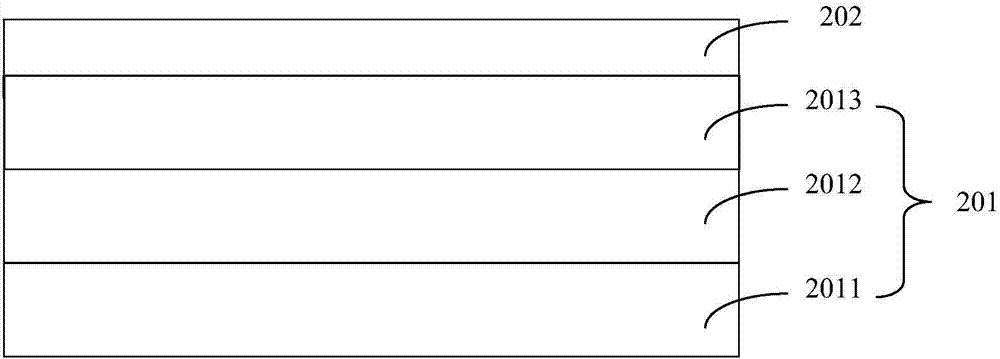

[0047] Such as Figure 2A As shown, a passivation layer 202 is formed on a GaN substrate 201 .

[0048] In this embodiment, the gallium nitride substrate 201 includes a Si substrate 2011 , a GaN layer 2012 and an AlGaN layer 2013 which are sequentially formed from bottom to top. Specifically, a layer of Si may be formed on the surface of the barrier layer of the AlGaN layer 2013. 3 N 4 layer as a passivation layer 202.

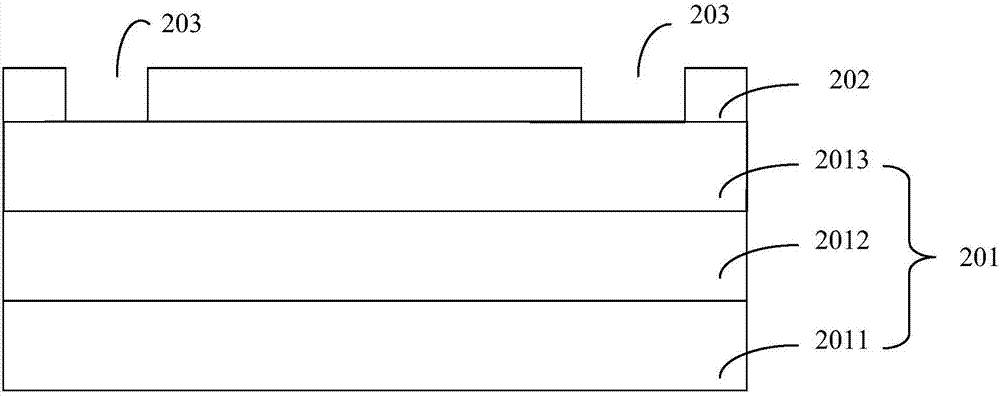

[0049] Such as Figure 2BAs shown, an ohmic contact hole 203 is formed in the passivation layer 202 to expose the gallium nitride substrate 201, and the ohmic contact hole 203 is surface treated.

[0050] For example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com