Straw, rice hull fibre base wood-plastic composite material and manufacture method thereof

A wood-plastic composite material and fiber-based technology, which is applied in the field of straw and rice husk fiber-based wood-plastic composite materials and their preparation, can solve the problems of difference in interaction between wood-plastic two interfaces, rough product surface, poor mechanical properties, etc., to achieve Prevent surface roughness, improve physical and mechanical properties, and have good anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw material composition of straw and rice husk fiber-based wood-plastic composite profiles by weight percentage:

[0030] Melamine resin 3.5% Straw (husk) fiber 60%

[0031] Low-density polyethylene 32% Maleic anhydride, acrylic acid, styrene-ethylene copolymer 2%

[0032] Simethicone 2.5%;

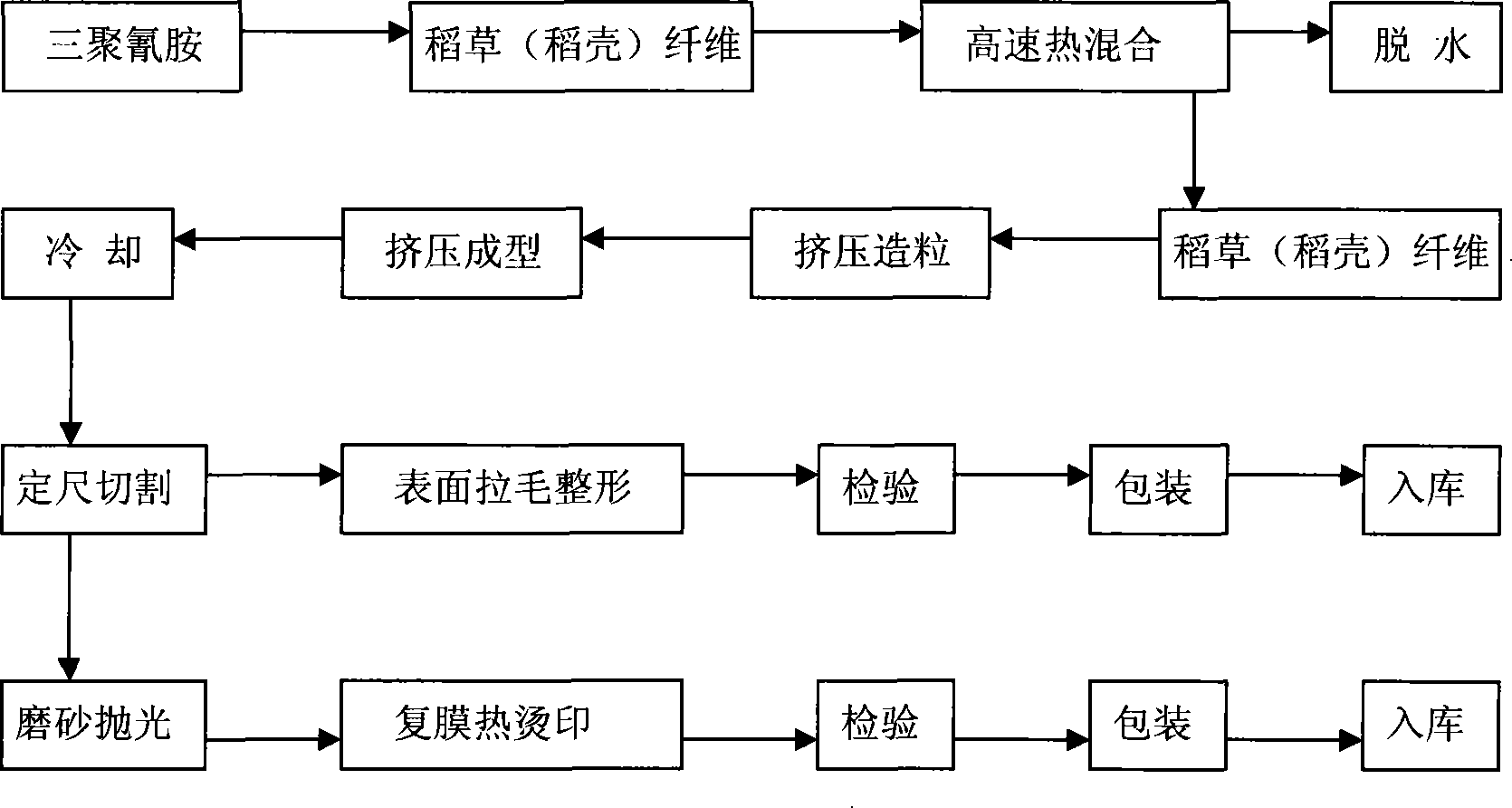

[0033] Such as figure 1 Shown, the preparation method of above-mentioned rice straw, rice husk fiber-based wood-plastic composite profile is as follows:

[0034] (1) The melamine resin, rice straw, and rice husk fibers are mixed at high speed by a conical twin-screw extruder, and the temperature of the high-speed heat mixing is 200°C, and dehydration is performed to obtain modified straw and rice husk fibers;

[0035] (2) the above-mentioned obtained modified rice straw, rice husk fiber are mixed with low-density polyethylene, solubilizer, lubricant, extruded and granulated;

[0036] (3) extruding the particles obtained by granulation, cooling and cutting;

[0037] (4) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com