Meal mixer capable of rotating meal barrel in three-dimensional way

A three-dimensional rotating and powder mixer technology, applied in mixers, mixers, chemical instruments and methods with rotating containers, etc., can solve the problems of poor strength of parts, flying dust, inability to mix evenly, etc., to prevent surface roughness. , The effect of preventing the deterioration of the strength of the parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

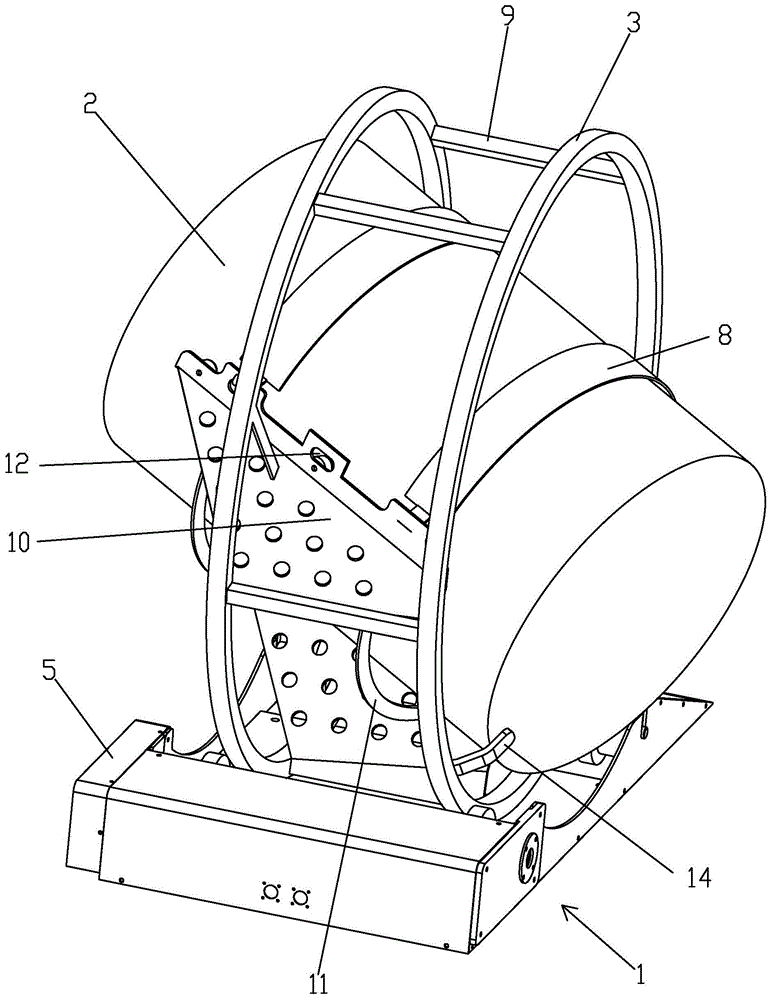

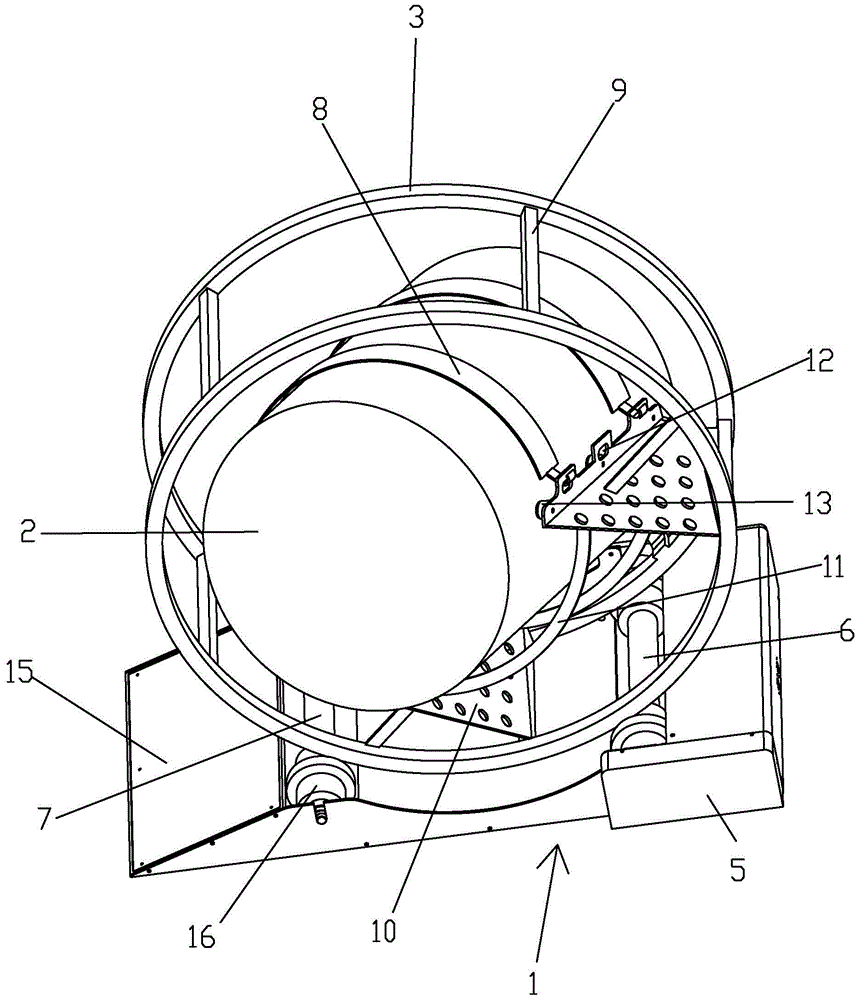

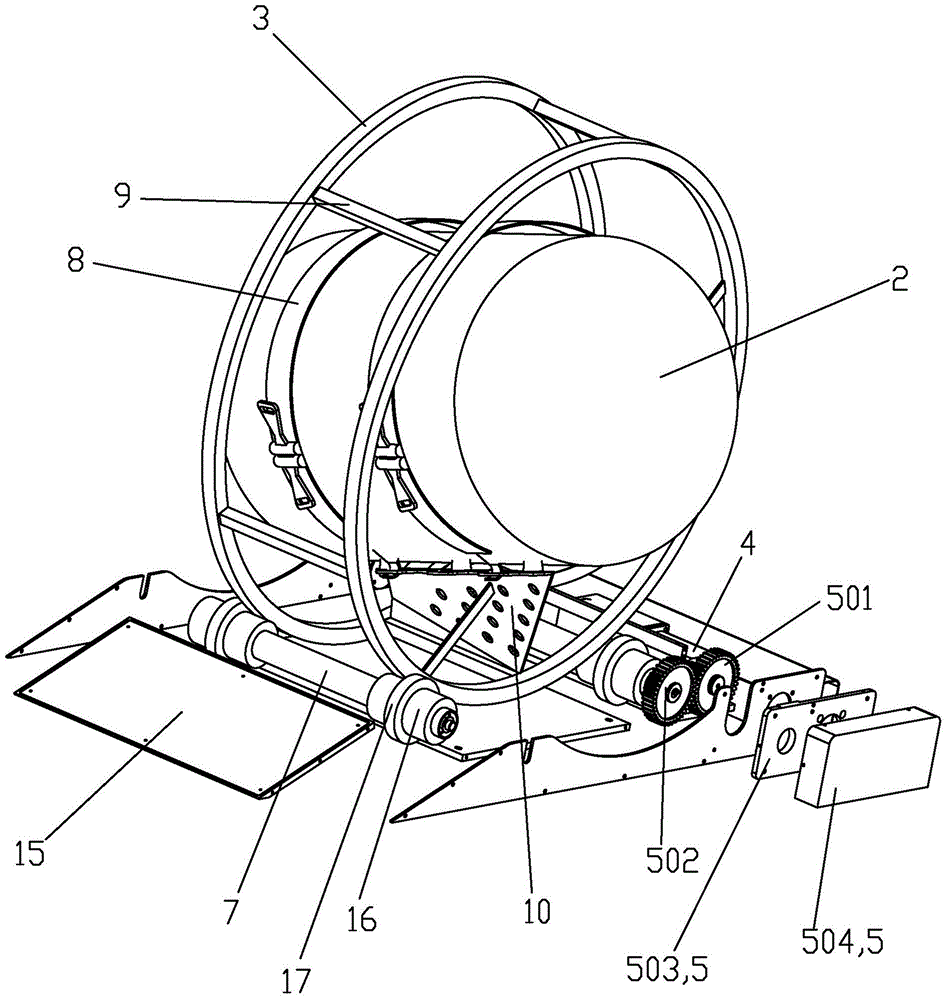

[0026] The technical features of the present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate the understanding of those skilled in the art.

[0027] A powder mixer capable of three-dimensionally rotating a powder bucket, comprising a base 1 and a roller frame 3 capable of obliquely fixing a sealed powder bucket 2 to rotate the powder bucket 2 three-dimensionally, and the base 1 is respectively provided with a driving motor 4, The gear box 5 connected with the drive motor 4 and the first shaft 6 connected with the gear box 5 are provided with a second shaft 7 at the other end of the base 1, and the roller frame 3 is rotatably placed On the first rotating shaft 6 and the second rotating shaft 7, such as Figure 1 to Figure 3 shown.

[0028] The powder mixer capable of three-dimensionally rotating the powder bucket as described above further includes a plurality of straps 8 for obliquely binding the powder bucket 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com