Film bulk acoustic resonator and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of film thickness distortion of the piezoelectric layer and its electrodes, influence of device structure reliability, complex and cumbersome process, etc., to improve crystal quality , low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

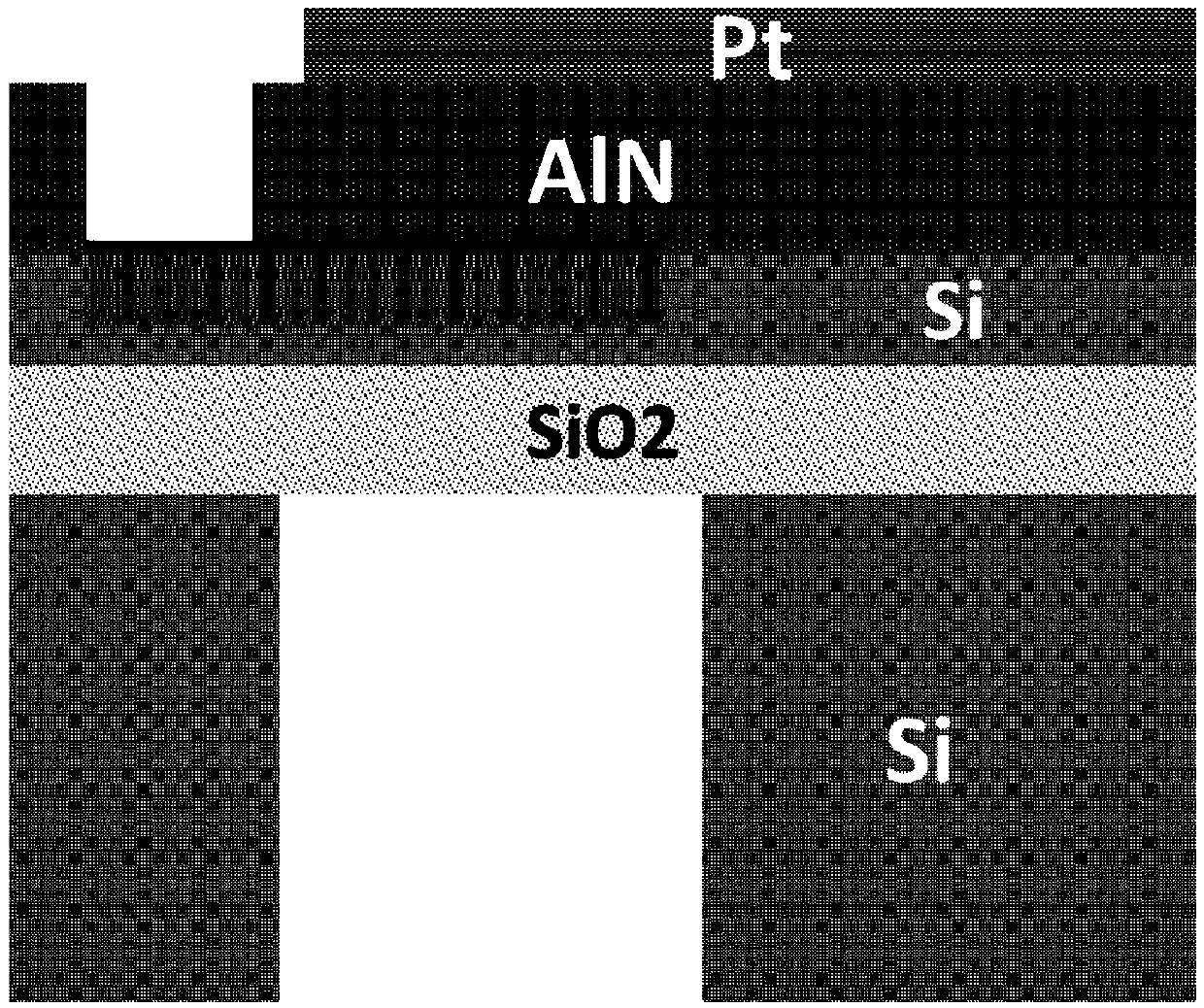

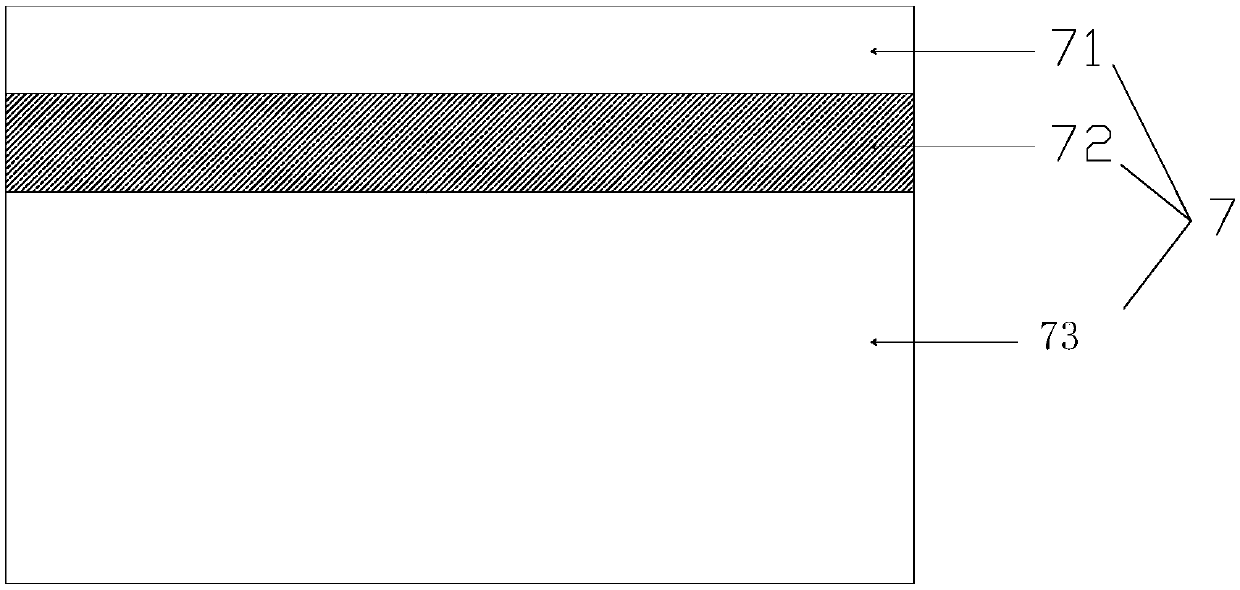

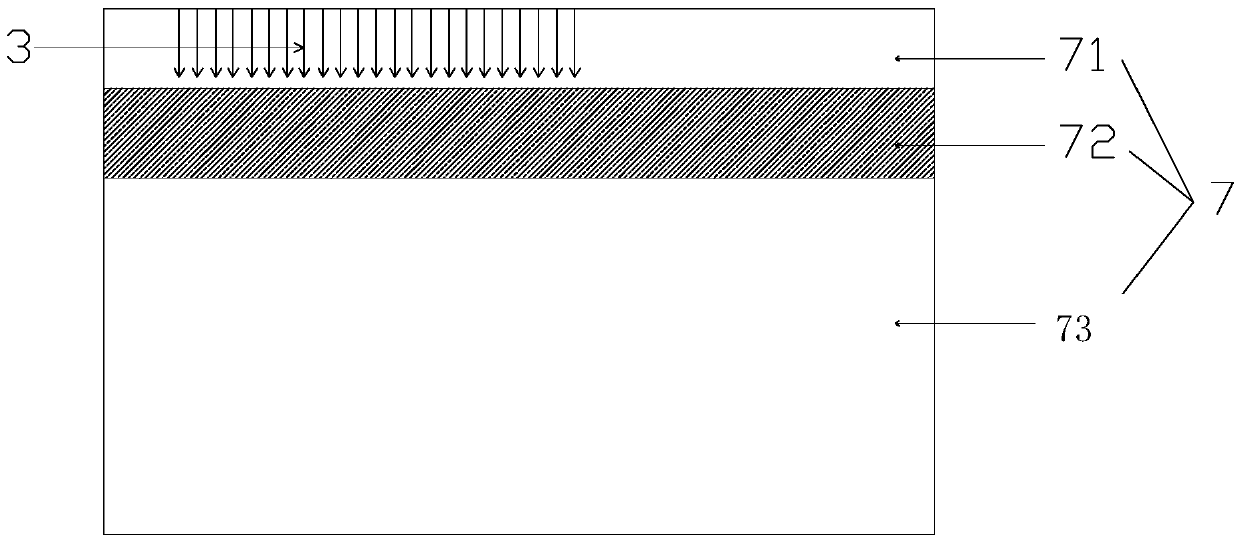

[0052] see Figure 7 and Figure 8 , a kind of thin film bulk acoustic resonator comprises SOI substrate 7, the lower electrode 3, piezoelectric layer 6 and top electrode 1 that are arranged on the first surface (front side) of SOI substrate 7 successively, on the second side of SOI substrate 7 The surface (back side) is provided with an air cavity 5, the depth of the air cavity is about 200 μm, and the area of the air cavity is about 150 μm*150 μm; wherein the lower electrode 3 is the top layer silicon 71 of the SOI substrate 7 in the selected area after ion implantation The highly doped conductive silicon layer formed by the method conversion is also provided with a through hole 2 communicating with the outside world in the corresponding area between the piezoelectric layer 6 and the lower electrode 3; the air cavity 5 is arranged in the back substrate 73 of the SOI substrate 7; wherein The SOI substrate 7 includes a top layer of silicon 71 , a back substrate 73 and an ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com