Diesel engine silencer used for high-power agricultural machinery

A technology for agricultural machinery and mufflers, which is applied in mechanical equipment, mufflers, machines/engines, etc., can solve problems such as affecting people's health and affecting the work efficiency of staff, and achieves poor high-frequency noise elimination. Simple and compact, small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing:

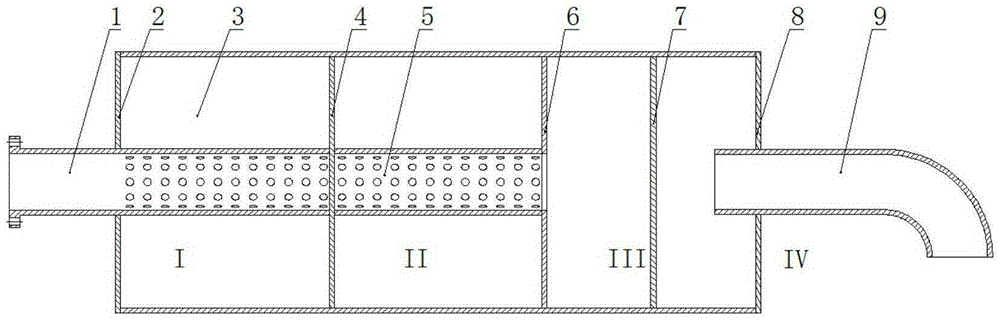

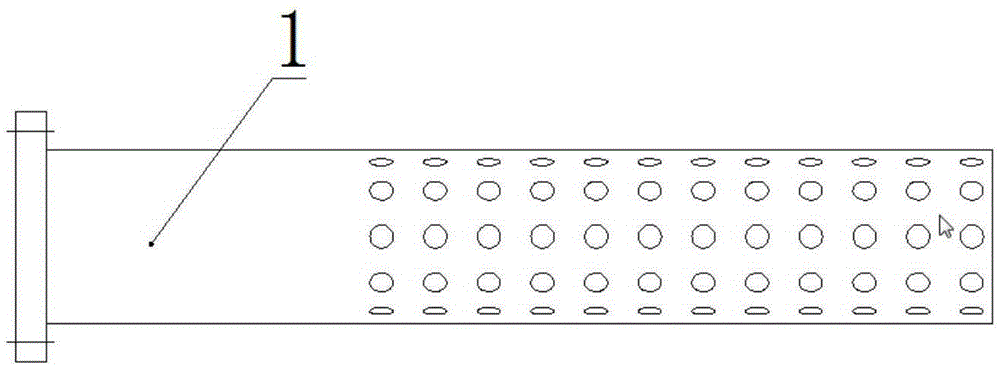

[0032] refer to figure 1, the high-power agricultural machinery diesel engine muffler (abbreviated as muffler) of the present invention comprises muffler intake pipe 1, muffler shell 3, No. 1 micro-perforated plate 4, micro-perforated pipe 5, expansion chamber partitions 6, 2 No. micro-perforated plate 7 and muffler exhaust pipe 9.

[0033] All components are fixedly connected to each other by welding to ensure the firmness of the space structure of the muffler and the airtightness of the muffler except for the inlet and outlet holes at both ends.

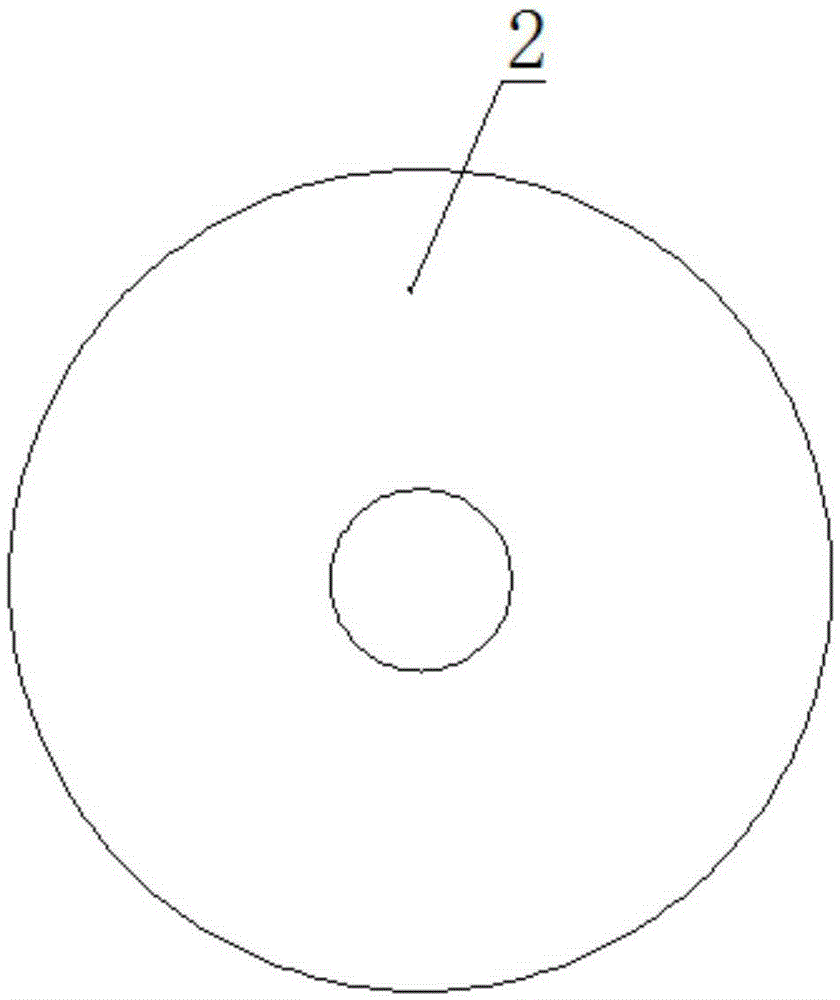

[0034] refer to Figure 4 , the muffler shell 3 is a cylindrical structure, which is composed of the muffler shell, the muffler front cover 2 and the muffler rear cover 8; wherein: the muffler shell is cylindrical with open ends Cylindrical pieces. The two ends of the muffler shell are sequentially welded together with the muff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com