Method for forging screw and nut

A nut and screw technology, applied in the field of forging, can solve the problems of failure to meet the standard, very high performance requirements of forgings, localization of screws and nuts, etc., and achieve the effect of improving reliability and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

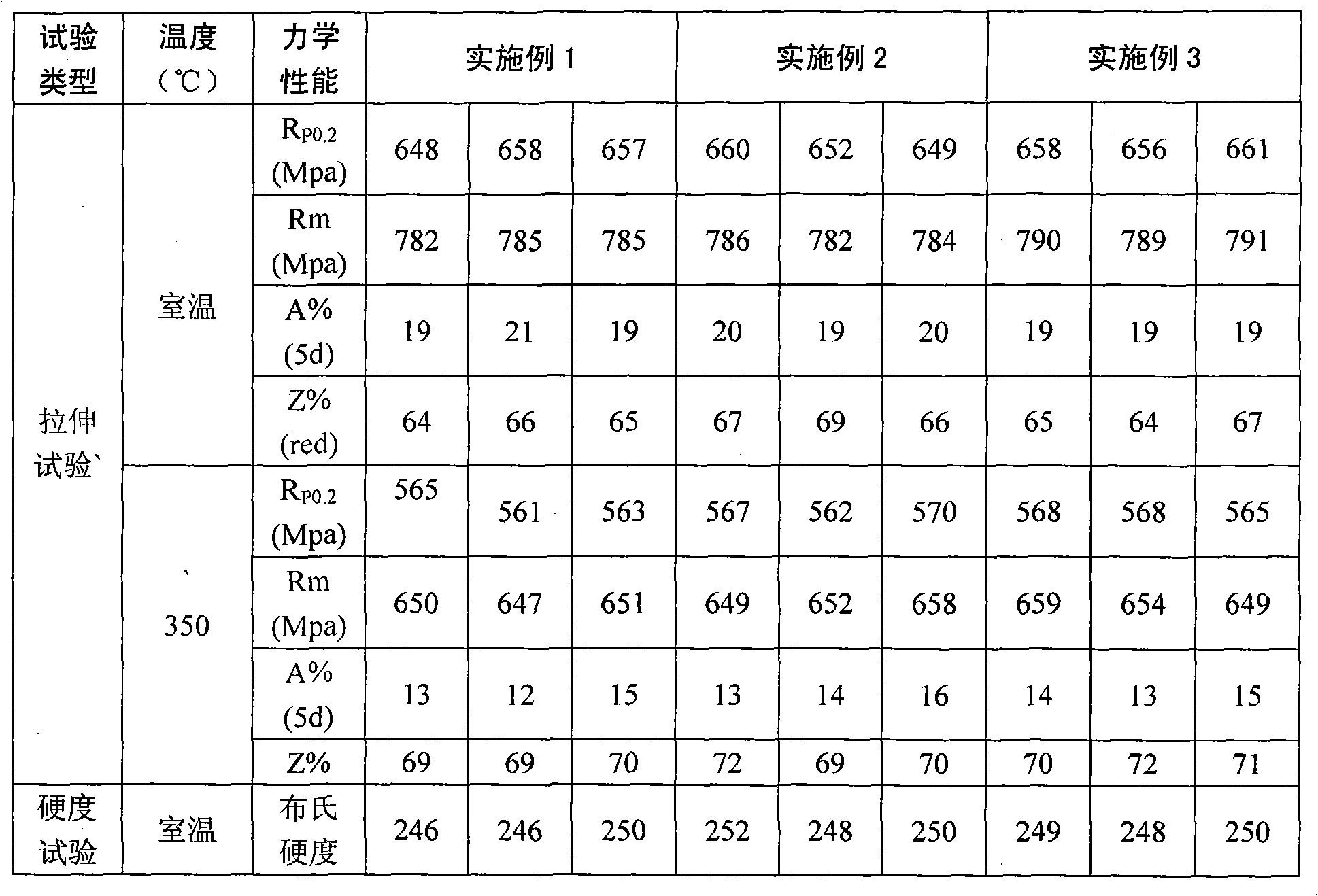

Embodiment 1

[0031] Embodiment 1: the requirement of manufacturing process among the present embodiment is:

[0032] 1. Forging:

[0033] a) heating the steel ingot to 700°C and keeping it warm for 3h; then heating it for 3h to make the temperature reach 1150°C and keeping it warm for 1h;

[0034] b) In the temperature range of 1150°C-850°C, upsetting and elongating the workpiece generated in step b), and then straightening, correcting the size, and rounding to make the forging ratio greater than 4, so as to forge the screw rod and The body of the nut.

[0035] 2. Performance heat treatment: When the surface temperature of the body after forging is not higher than 600°C, heat the green body to 980°C and keep it for 1h, cool it with oil to not higher than 100°C, then reheat it to the temperature range of 700°C and keep it for 3h , and then water-cooled.

[0036] Process requirements for performance heat treatment: immerse the green body in the oil tank, the immersion depth is ≥1.5M and m...

Embodiment 2

[0038] Embodiment 2: the requirement of manufacturing process among the present embodiment is:

[0039] 1. Forging:

[0040] a) heating the steel ingot to 700°C and keeping it warm for 3h; then heating it for 3h to make the temperature reach 1150°C and keeping it warm for 1h;

[0041] b) In the temperature range of 1150°C-850°C, upsetting and elongating the workpiece generated in step b), and then straightening, correcting the size, and rounding to make the forging ratio greater than 4, so as to forge the screw rod and The body of the nut.

[0042] 2. Performance heat treatment: When the surface temperature of the body after forging is not higher than 600°C, heat the body to 980°C and keep it warm for 1.5h, cool it with oil to not higher than 100°C, then reheat it to a temperature range of 705°C and keep it warm 3h, then water cooled.

[0043] Process requirements for performance heat treatment: immerse the green body in the oil tank, the immersion depth is ≥1.5M and move b...

Embodiment 3

[0045] Embodiment 3: the requirement of manufacturing process among the present embodiment is:

[0046] 1. Forging:

[0047] a) heating the steel ingot to 700°C and keeping it warm for 3h; then heating it for 3h to make the temperature reach 1150°C and keeping it warm for 1h;

[0048] b) In the temperature range of 1150°C-850°C, upsetting and elongating the workpiece generated in step b), and then straightening, correcting the size, and rounding to make the forging ratio greater than 4, so as to forge the screw rod and The body of the nut.

[0049] 2. Performance heat treatment: When the surface temperature of the body after forging is not higher than 600°C, heat the green body to 980°C and keep it for 2 hours, cool it with oil to not higher than 100°C, then reheat it to the temperature range of 710°C and keep it for 3 hours , and then water-cooled.

[0050] Process requirements for performance heat treatment: immerse the green body in the oil tank, the immersion depth is ≥...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com