Thermal interface material and preparation method thereof

A thermal interface material, carbon nanotube thin film technology, applied in heat exchange materials, chemical instruments and methods, nanotechnology for materials and surface science, etc. Improve overall performance, high thermal conductivity, and good compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

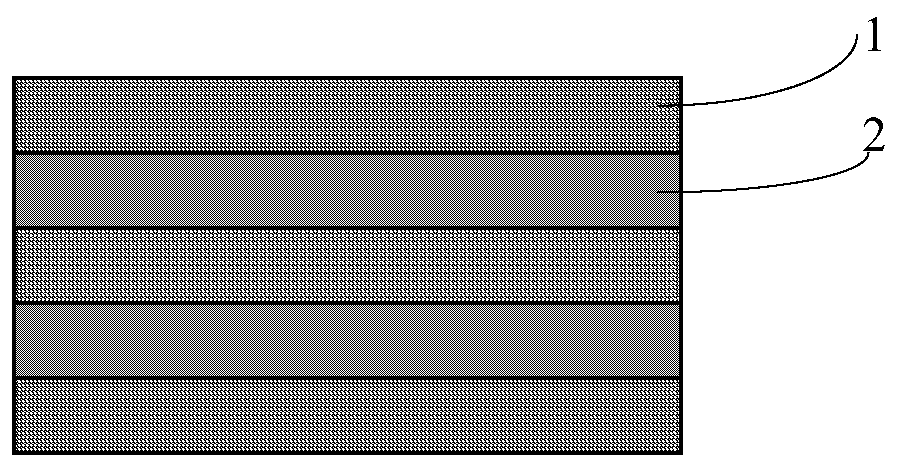

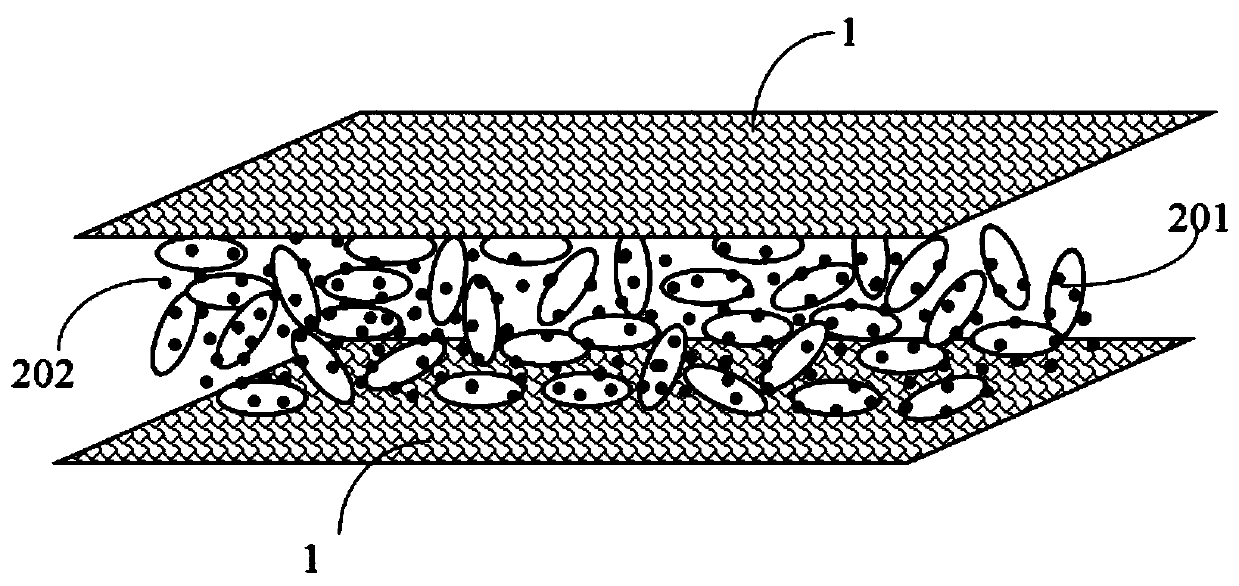

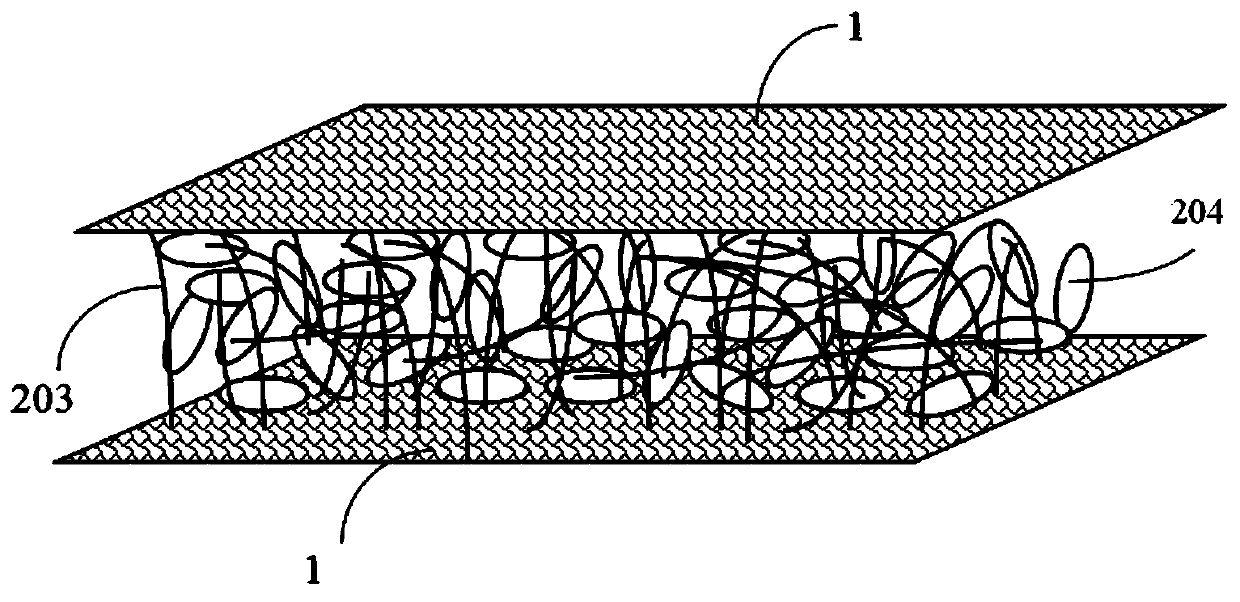

[0043] A preparation method of carbon nanotube-graphene-silicon carbide composite thermal interface material, such as Figure 4As shown, A-E is the process flow, that is, after the single-layer carbon nanotube film is compounded with a layer of nano-scale silicon oxide and graphene oxide coating, the process is repeated until the process of forming a multilayer composite carbon nanotube film. Specifically:

[0044] 1) The carbon nanotube film is prepared by the floating catalytic method, and rolled up, the winding length is 200m, and the average thickness of the carbon nanotube film on the roller is 2 microns;

[0045] 2) Prepare nano silicon dioxide and graphene oxide mixed dispersion solution, graphene mass concentration 25wt%, wherein the mass concentration of nano silicon dioxide is 5wt%; Adopt water as solvent, sodium dodecylbenzene sulfonate (SDBS) As a dispersant, the mass concentration of the dispersant is 2wt%, stirring and dispersing;

[0046] 3) Using the spraying...

Embodiment 2

[0051] A preparation method of carbon nanotube-graphene-silicon carbide composite thermal interface material, such as Figure 4 As shown, A-E is the process flow, that is, after the single-layer carbon nanotube film is compounded with a layer of nano-scale silicon oxide and graphene oxide coating, the process is repeated until the process of forming a multilayer composite carbon nanotube film. Specifically:

[0052] 1) The carbon nanotube film is prepared by the floating catalytic method, and rolled up, the winding length is 200m, and the average thickness of the carbon nanotube film on the roller is 2 microns;

[0053] 2) Prepare nano silicon dioxide and graphene oxide mixed dispersion solution, graphene mass concentration 30wt%, wherein the mass concentration of nano silicon dioxide is 5wt%; Adopt NMP as solvent, sodium dodecylbenzene sulfonate (SDBS) Dispersant, the concentration of dispersant is 2wt%, stirring and dispersing;

[0054] 3) Using the spraying method, evenly...

Embodiment 3

[0059] A preparation method of carbon nanotube-graphene-silicon carbide composite thermal interface material, such as Figure 4 As shown, A-E is the process flow, that is, after the single-layer carbon nanotube film is compounded with a layer of nano-scale silicon oxide and graphene oxide coating, the process is repeated until the process of forming a multilayer composite carbon nanotube film. Specifically:

[0060] 1) The carbon nanotube film is prepared by the floating catalytic method, and rolled up, the winding length is 200m, and the average thickness of the carbon nanotube film on the roller is 2 microns;

[0061] 2) Prepare nano silicon dioxide and graphene oxide mixed dispersion solution, graphene mass concentration 20wt%, wherein the mass concentration of nano silicon dioxide is 3wt%; Adopt water and NMP (mass concentration ratio is 10:1) as solvent, Sodium dodecyl sulfate (SDS) is used as a dispersant, and the concentration of the dispersant is 1wt%, stirring and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com