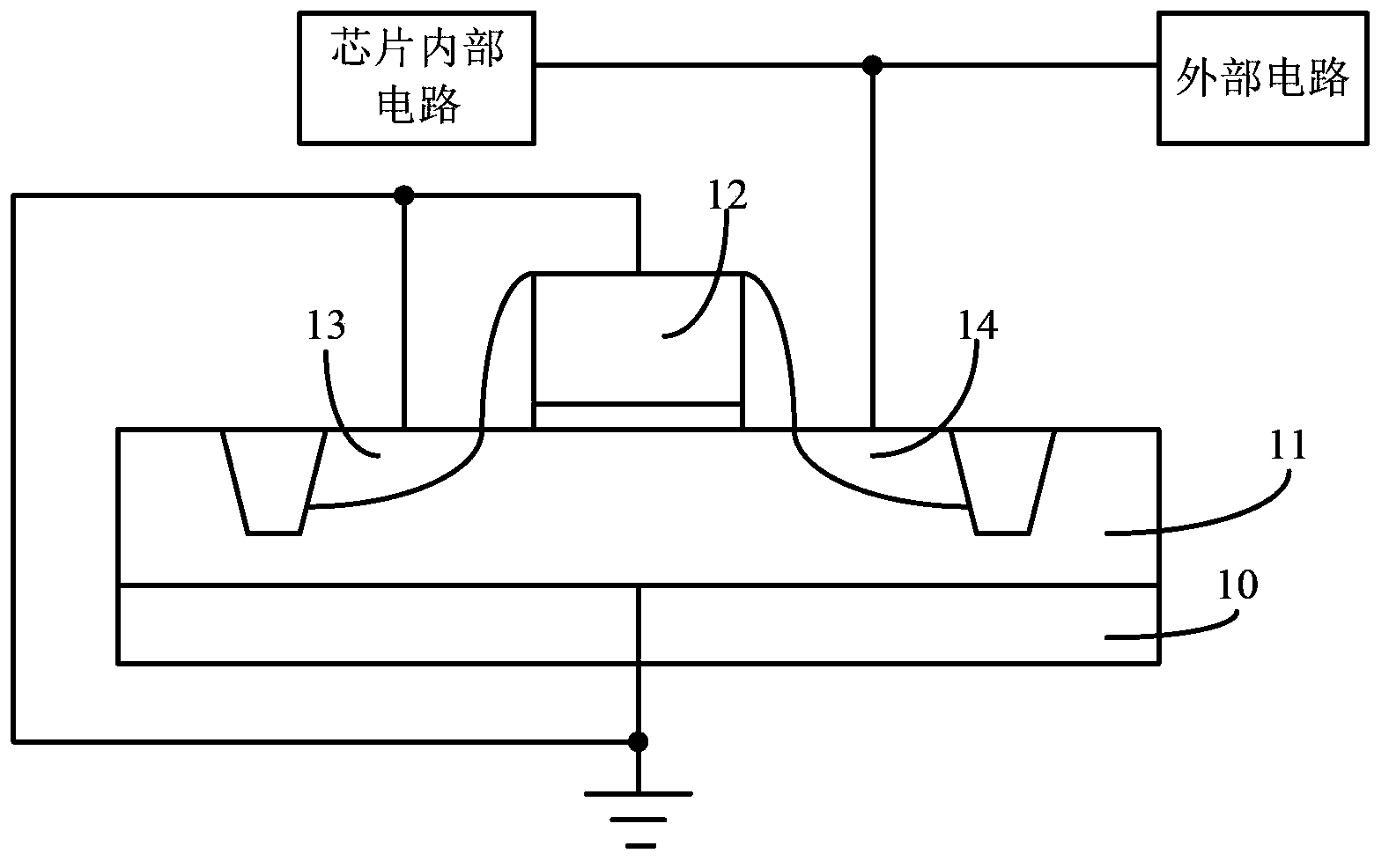

An electrostatic discharge protection structure

An electrostatic discharge protection and isolation structure technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as high breakdown voltage, inability to protect chips or semiconductor devices from electrostatic damage, and reduced chip energy consumption, and achieve heat dissipation capabilities. Good, the effect of eliminating heat accumulation and avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

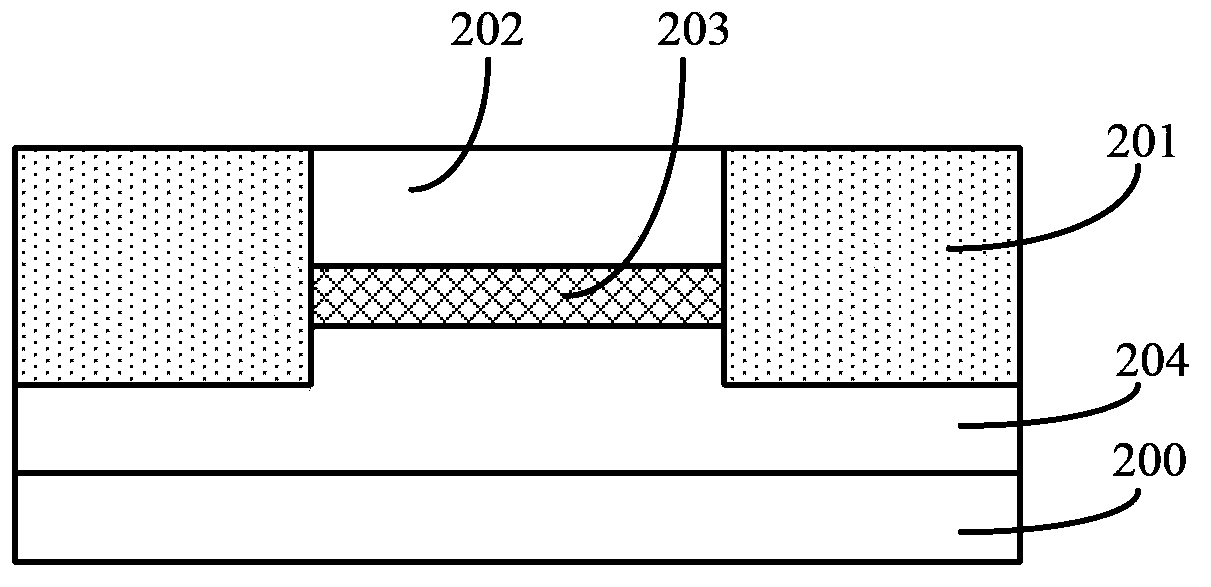

[0028] As mentioned in the background art, the breakdown voltage of the existing electrostatic discharge protection structure is too high to meet the technical requirements for protecting low-voltage chips or devices.

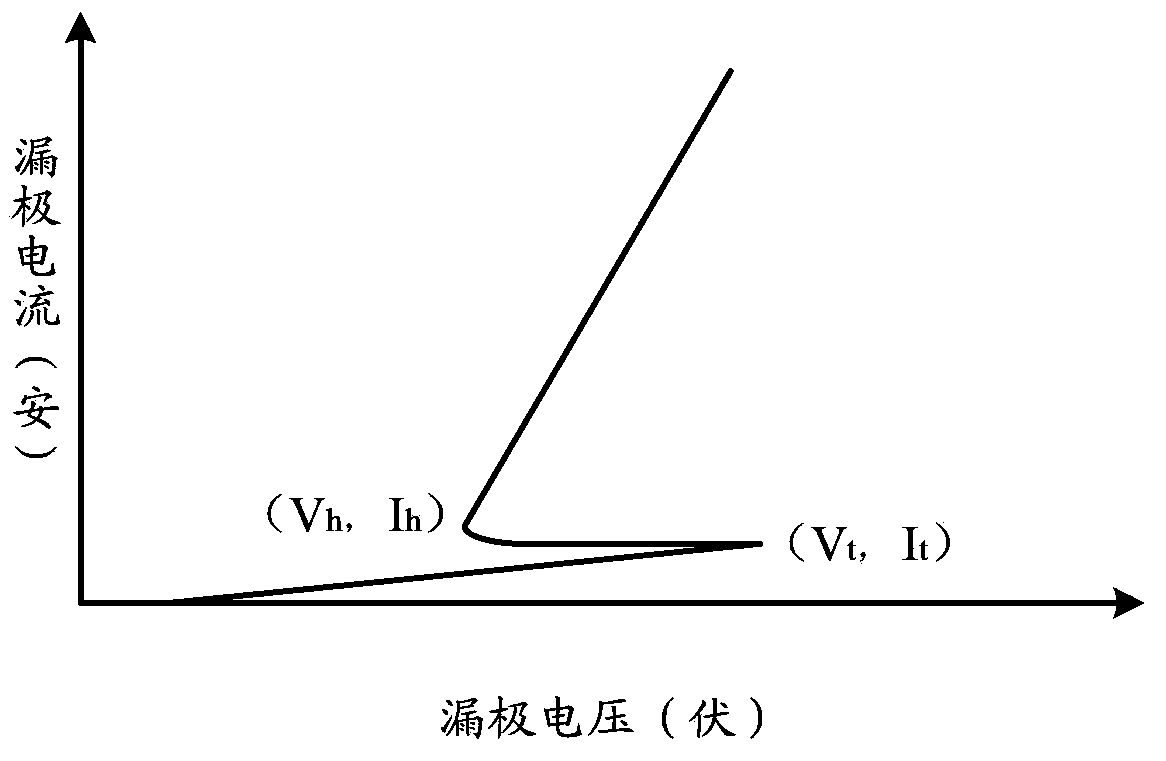

[0029] Existing grounded N-type field effect transistor breakdown voltage V t Typically 5.8V. As the size of a chip or semiconductor device decreases, its operating voltage also decreases accordingly, and the voltage that can cause damage to the chip or semiconductor device also decreases accordingly. Taking the transistor whose operating voltage is reduced to 1.2V as an example, please refer to Figure 8 , is the I / V characteristic diagram of the gate current and gate voltage of the transistor with the operating voltage of 1.2V. Due to the reduction in the size of the transistor, the thickness of the gate oxide layer in the transistor is also reduced accordingly, resulting in The breakdown voltage of the gate oxide V b(breakdown voltage) is reduced to 5.9V....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com