Method for preparing catalyst for electrical catalytic degradation of organic wastewater

A technology for electrocatalytic degradation and organic wastewater, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrochemical water/sewage treatment, etc., can solve the problems of reducing catalytic degradation effect, coating peeling off, difficult morphology of anode materials, etc. problem, to achieve the effect of strong controllability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

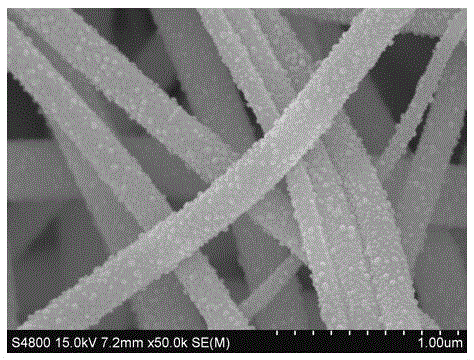

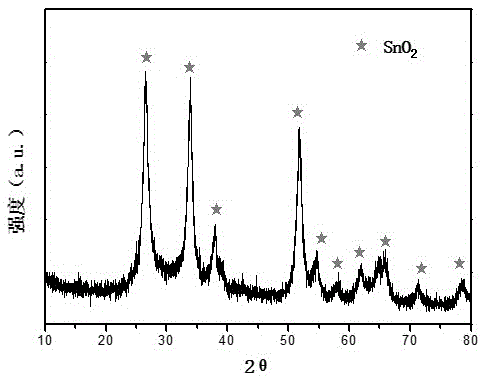

[0022] Example 1: Weigh 2g of polyvinylpyrrolidone (PVP) into a solvent composed of 9g of ethanol and 9g of N-N dimethylformamide (DMF), stir for 12 hours until the solution is clear and transparent, and then weigh 2g of PVP SnCl 4 ·5H 2 O was added to the above solution and stirred until the solution became clear and transparent to obtain the spinning solution.

[0023] Put the spinning solution into a 10mL syringe for spinning and control the spinning conditions. The spinning voltage is 24kv, the temperature is 35°C, the humidity is 30%, the receiving distance is 15cm, and the spinning speed is 0.2mm / min, to obtain SnCl 4 ·5H 2 For composite nanofibers with O / PVP=1, the composite nanofibers are calcined at 500°C for 3 hours at a heating rate of 3°C / min in air to obtain inorganic SnO 2 Nanofibers.

[0024] The metal oxide nanofibers, acetylene black, polytetrafluoroethylene, and ethanol were mixed in a mass ratio of 80:10:5:5, stirred for 24 hours, and ultrasonically trea...

example 2

[0029] Example 2: Similar to the steps in Example 1, weigh 2.5g of polyvinylpyrrolidone (PVP) and add it to 18gN-N dimethylformamide solvent, stir for 12h until the solution is clear and transparent SnCl 4 ·5H 2 O was replaced with 2 g of iron acetylacetonate. Made Fe 2 o 3 With nanofibers, the removal rate of electrocatalytic phenol wastewater was 84.64%, and the removal rate of COD was 66.11%; the removal rate of methylene blue was 89.23%, and the removal rate of COD was 69.43%; The removal rate was 10.11%.

example 3

[0030] Example 3: Similar to the steps in Example 1, weigh 2g of polyvinylpyrrolidone (PVP) and add it to 18g of ethanol solvent, stir for 12h until the solution is clear and transparent, add 2g of SnCl 4 ·5H 2 O was replaced by 2 g of manganese acetate. MnOx nanofibers were prepared, the removal rate of electrocatalytic phenol wastewater was 84.23%, the removal rate of COD was 42.23%; the removal rate of methylene blue was 83.47%, the removal rate of COD was 57.93%; the removal rate of Congo red wastewater was 80.93%, COD removal rate was 7.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com