Preparation method for carbon coated composite metal oxide electrode material

A composite metal and oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory improvement in charge-discharge performance and cycle performance, difficulty in controlling the amount of coated carbon, and sudden drop in battery performance. Achieve improved cycle performance, thickness uniformity, prevention of agglomeration and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Add 0.05mol FeCl to 500mL deionized water 3 ·6H 2 O, 0.12mol SnCl 4 ·5H 2 O and 0.15mol citric acid, stirred and dissolved; the temperature of the solution was raised to 78°C, and kept for 5 hours; Aged for 12 hours; the obtained solid was calcined at 450°C for 3 hours in an air atmosphere to obtain carbon-coated SnO 2 -Fe 2 o 3 Composite oxide sample, the carbon coating amount of this material is 6% by mass.

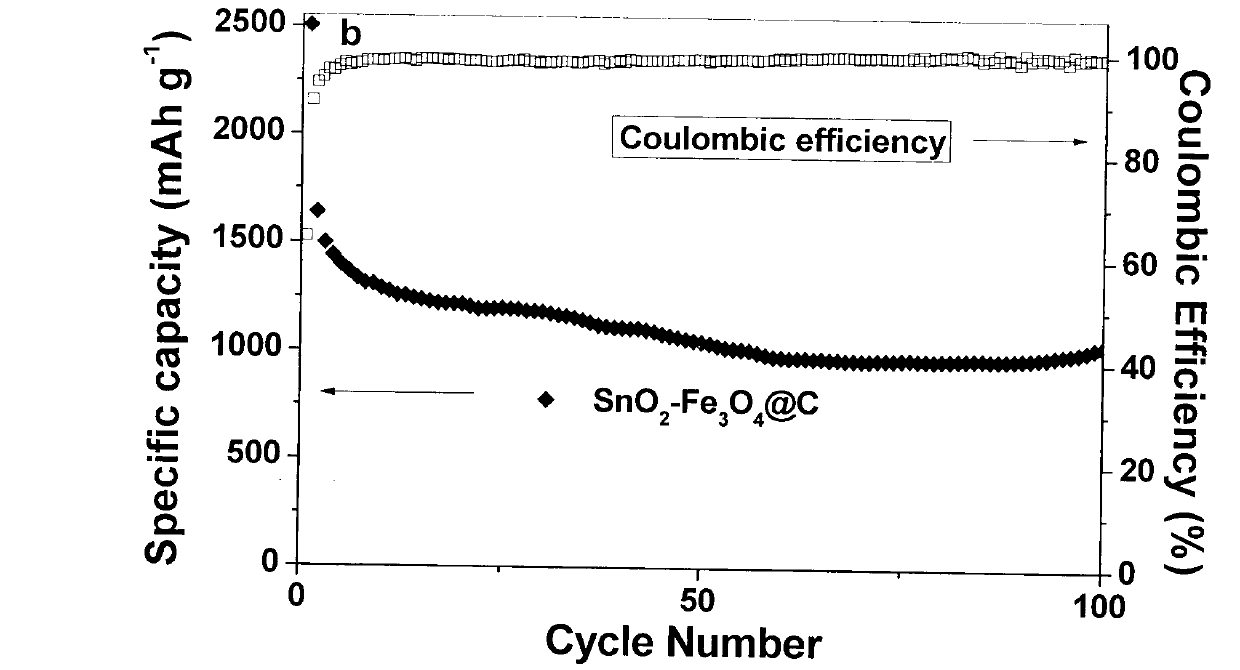

[0013] During the electrochemical performance test of the material, the slurry was mixed according to the ratio of electrode material: acetylene black: binder = 8:1:1 (mass ratio), evenly coated on the copper foil current collector, and pressed after the electrode sheet was dried. The load of active substance is 1-2mg / cm 2 , the counter electrode selected in the single-electrode charge-discharge test is metal lithium, with 1MLiPF 6 - EC / DMC / EMC (volume ratio 1:1:1) is used as the electrolyte, assembled into a button battery.

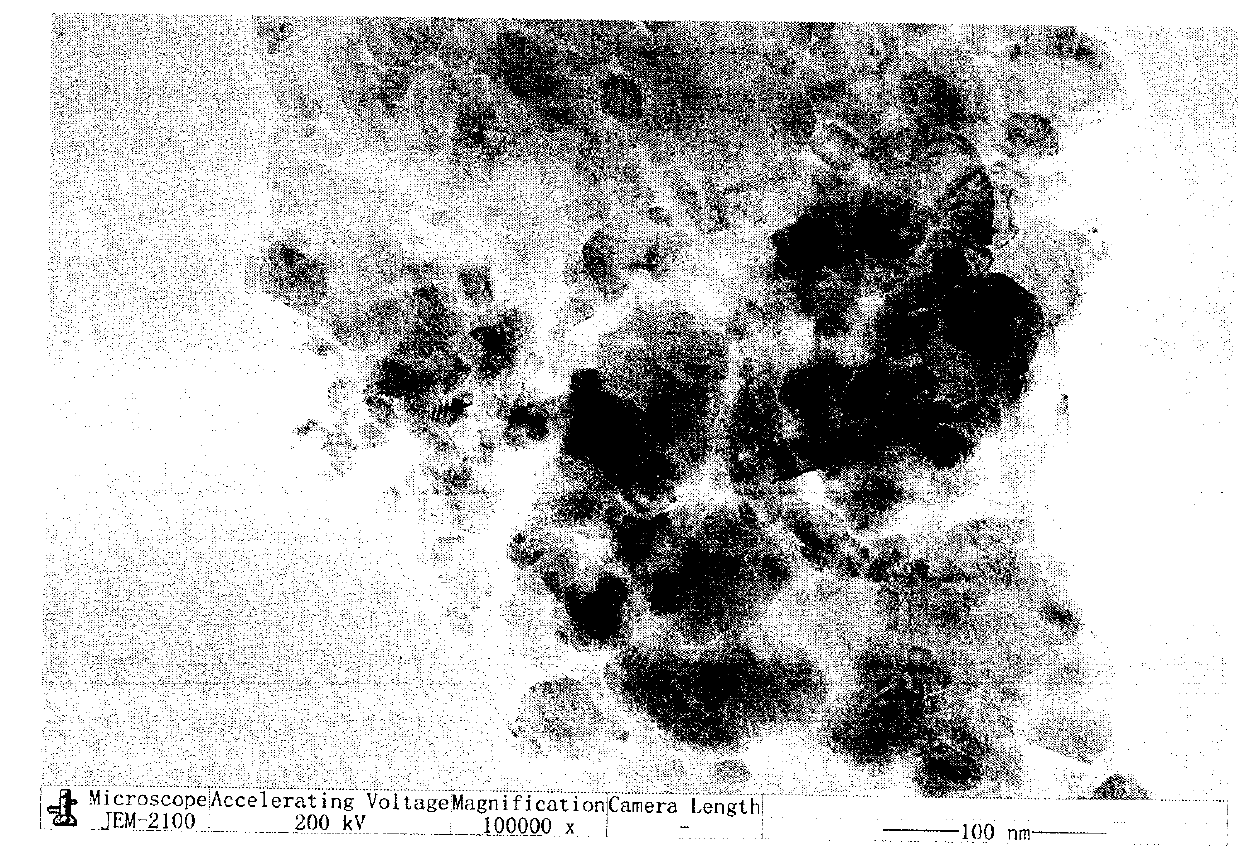

[0014] figure 1 Transmissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com