Method for manufacturing metal oxide electrode and organci light emitting display using the same

An oxide and display technology, applied in the direction of electric solid device, metal material coating process, circuit, etc., can solve problems such as low sheet resistance and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings.

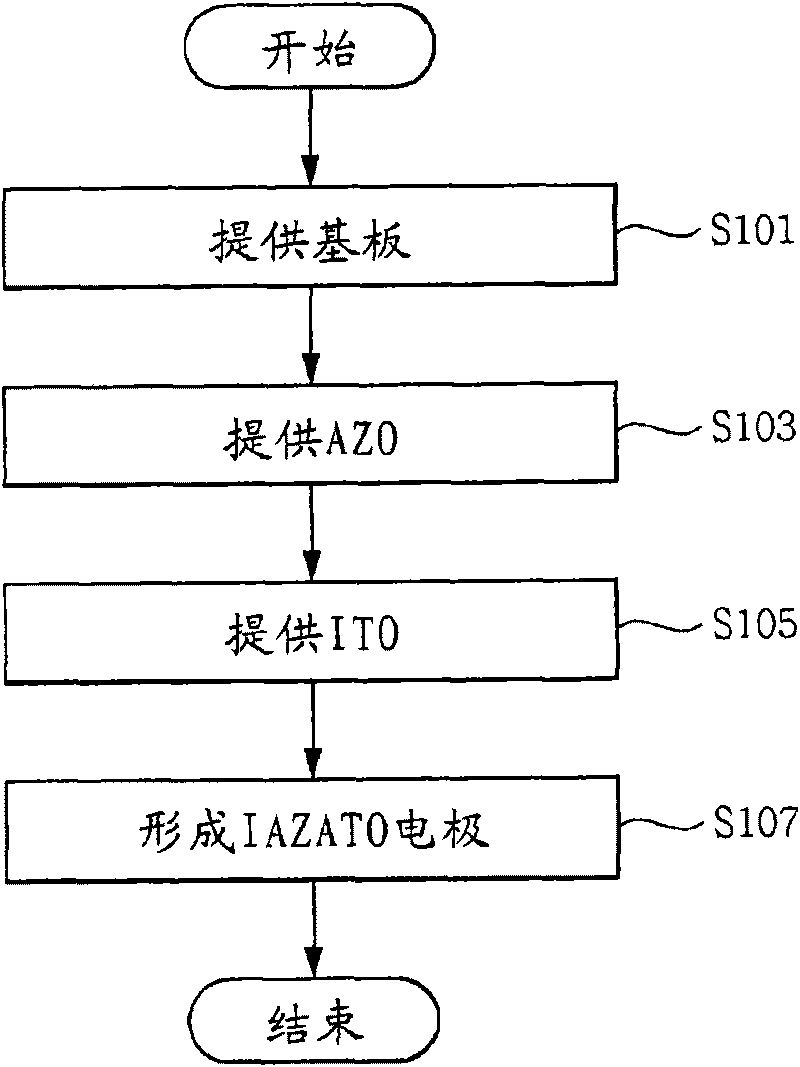

[0019] An exemplary manufacturing method of the display device according to the embodiment will be described below.

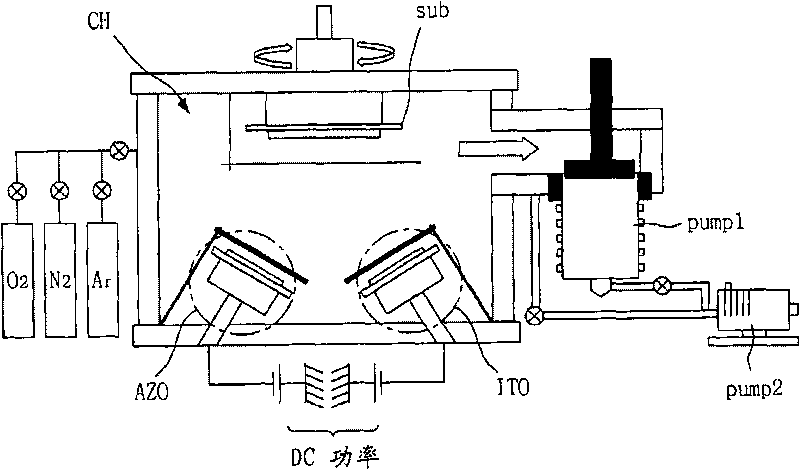

[0020] figure 1 A dual target direct current (DC) sputtering system used to fabricate metal oxide electrodes is schematically shown. Such as figure 1 As shown, the dual-target DC sputtering system includes a diffusion pump pump1, a rotary pump pump2, and the like. The substrate sub and the two materials connected to the DC power supply unit are placed inside the chamber CH of the dual-target DC sputtering system.

[0021] In a dual-target DC sputtering system, such as oxygen (O 2 ), nitrogen (N 2 ), argon (Ar) gases are injected into the chamber CH, and DC power is applied to the two materials. Therefore, sources generated from these two materials are formed on the substrate sub.

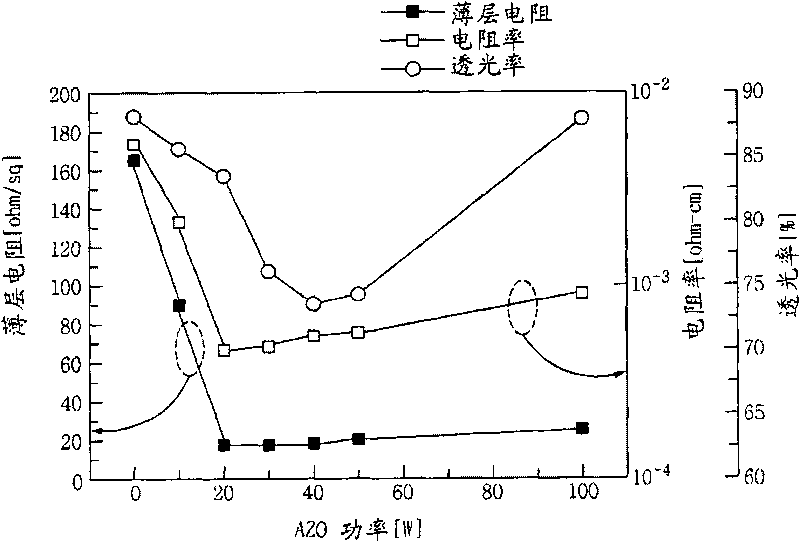

[0022] The following will refer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com