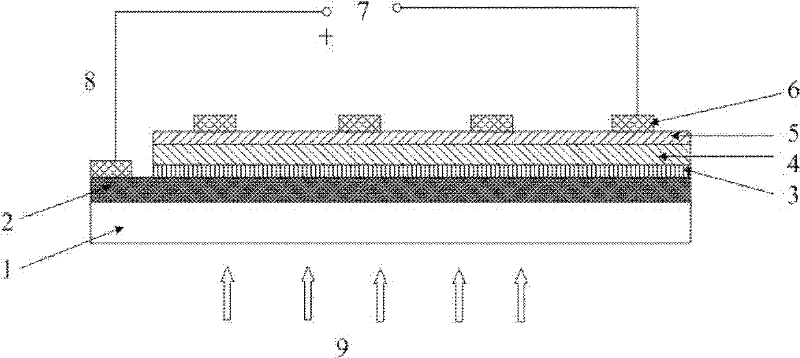

Polymer solar battery with inverted structure and fabrication method thereof

A reverse structure, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unfavorable device stability and life, poor battery stability, and easy oxidation of the negative electrode, and achieve high photoelectric conversion efficiency , effective collection, efficient collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

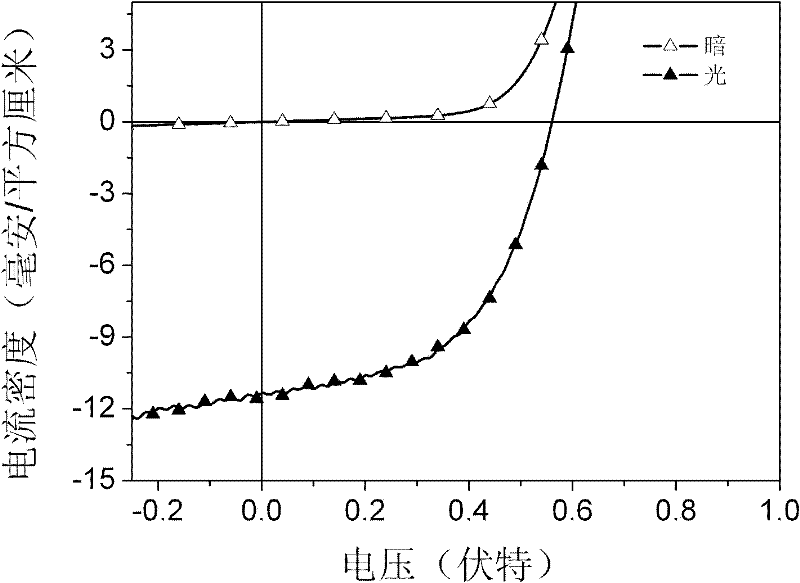

[0028] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol in sequence, dried with nitrogen, and spin-coated with 3.75 mg / mL diisocyanate at 4000 rpm. Propoxybis(acetylacetonate)titanium isopropanol solution, baked at 150° C. for 10 minutes, and cooled naturally to obtain an electron collection layer. A 1:1 (mass ratio) mixed solution of 20 mg / mL P3HT and PCBM was directly spin-coated on the above-mentioned electron collection layer at a rotational speed of 800 rpm as a photoelectric active layer. Then at 4×10 -4 Vacuum deposition of 20nm MoO at Pa 3 , to obtain a hole-collecting layer. Finally, at 4×10 -4 100nm aluminum was vacuum-deposited under Pascal as an electrode. In the obtained reverse structure polymer solar cell, the thickness of diisopropoxy bis(acetylacetonate)titanium film is figure 2 The current-voltage curves of the device without light irradiation an...

Embodiment 2

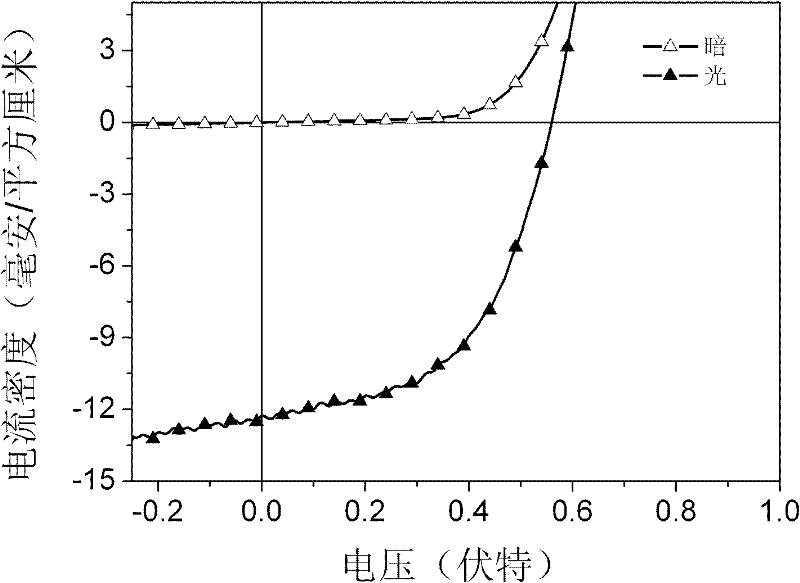

[0030] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol in sequence, dried with nitrogen, and spin-coated with 3.75 mg / mL diisocyanate at 4000 rpm. Propoxybis(acetylacetonate)titanium isopropanol solution, baked at 150° C. for 10 minutes, and cooled naturally to obtain an electron collection layer. A 1:1 (mass ratio) mixed solution of 20 mg / mL P3HT and PCBM was directly spin-coated on the above-mentioned electron collection layer at a rotational speed of 1500 rpm as a photoelectric active layer. Then at 4×10 -4 Vacuum deposition of 20nm MoO at Pa 3 , to obtain a hole-collecting layer. Finally, at 4×10 -4 50nm silver was vacuum-deposited under Pascal as an electrode. In the obtained reverse structure polymer solar cell, the thickness of diisopropoxy bis(acetylacetonate)titanium film is image 3 The current-voltage curves of the device without light irradiation and w...

Embodiment 3

[0032] The transparent conductive glass sputtered with indium tin oxide (ITO) was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol in sequence, dried with nitrogen, and spin-coated with 3.75 mg / mL diisocyanate at 4000 rpm. Propoxybis(acetylacetonate)titanium isopropanol solution, baked at 150° C. for 10 minutes, and cooled naturally to obtain an electron collection layer. Combine 12.5mg / mL of P9001 with PC 70 BM 1:1.5 (mass ratio) mixed solution was added with 3% diiodooctane additive, and then the solution was directly spin-coated on the above-mentioned electron collection layer at a rotational speed of 1500 rpm as a photoelectric active layer. Then at 4×10 -4 Vacuum deposition of 24nm MoO at Pa 3 , to obtain a hole-collecting layer. Finally, at 4×10 -4 100nm aluminum was vacuum-deposited under Pascal as an electrode. In the obtained reverse structure polymer solar cell, the thickness of diisopropoxy bis(acetylacetonate)titanium film is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com