Positive and negative alternate electrolysis-resistance metal oxide electrode

A technology of oxide and oxide coating, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of the reduction of anode chlorine evolution efficiency, metal oxide electrode damage, and influence on electrode stability, etc., to achieve excellent positive resistance The effect of anti-alternating electrolytic performance, slow reduction and consumption, and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

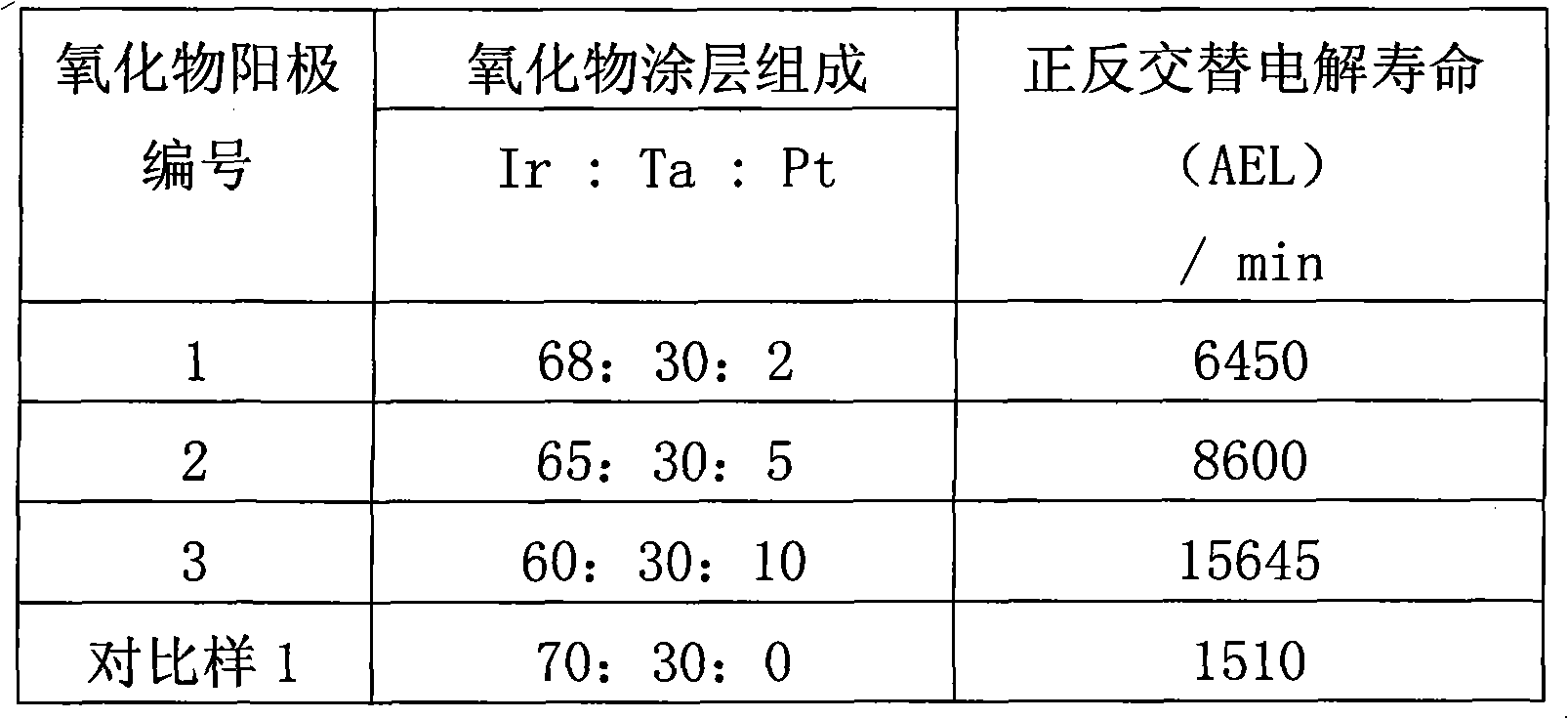

Embodiment 1

[0012] Using TA2 industrial pure titanium plate as the electrode substrate, the surface of the titanium plate test piece after sandblasting treatment was rinsed with water, and then etched in an oxalic acid solution with a temperature of 90°C and a concentration of 10% (mass fraction) for 2 hours to obtain Uniform rough surface; the oxide coating is prepared by the sol-gel method: first, citric acid and ethylene glycol are miscible, and the molar ratio of the two is 1:5, and then chloroiridic acid, tantalum pentachloride and chlorine Platinic acid is added in the mixed solution of citric acid and ethylene glycol by a certain Ir: Ta: Pt molar ratio (see Table 1 for details), and the solvent is adjusted so that the molar concentration of the metal in the solution is 0.25mol / L; Stir to obtain a colloidal solution containing mixed metal ions; paint the colloidal solution on the treated titanium test piece, dry it with an infrared lamp, and then thermally oxidize it at 500°C for 10 ...

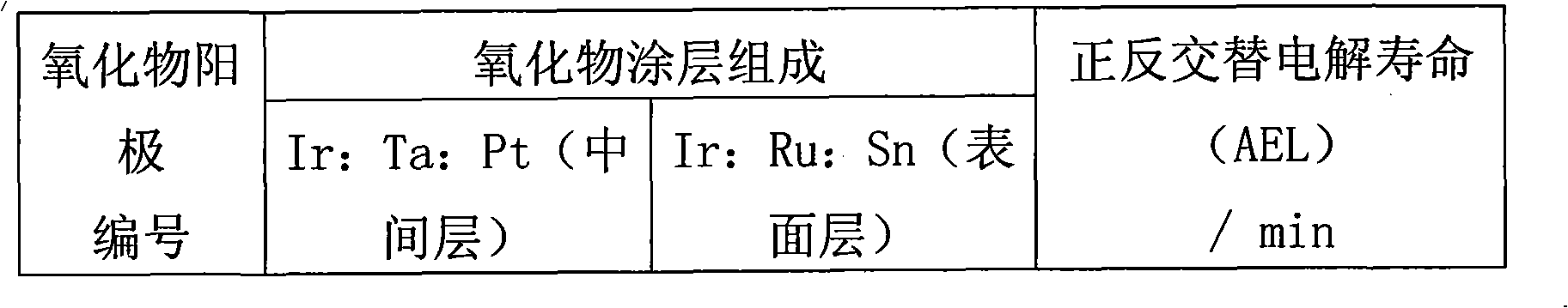

Embodiment 2

[0017] Adopt the same method as embodiment 1 to form IrO on the titanium substrate 2 -Ta 2 o 5 -PtO x Coating, its composition Ir:Ta:Pt molar ratio is 68:30:2, coating loading is about 6g / m 2 , and then prepare IrO on it 2 -RuO 2 -SnO 2 Oxide coating to form a composite electrode embedded in the middle layer; the surface layer was prepared by thermal decomposition: chloroiridic acid, ruthenium trichloride, and tin tetrachloride were added to ethyl alcohol at a molar ratio of Ru:Ir:Sn of 20:20:60. In the propanol solution, a coating solution is formed; the solution is painted on the electrode coated with the intermediate layer, dried with an infrared lamp to form a gel, and then thermally oxidized at a temperature of 450 ° C for 10 minutes to obtain a mixed metal oxide film layer. Repeat the above brushing, drying and thermal oxidation process several times to make the oxide load in the surface coating reach about 12g / m 2 ; In addition, using the same composition and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com