Preparation method of foam nickel-loaded composite nano metal oxide electrode material

A technology of electrode materials and nano-metals, which is applied in the field of preparation of foamed nickel-loaded composite nano-metal oxide electrode materials, can solve problems such as poor practicability, and achieve the effects of good loading capacity, high sensitivity, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

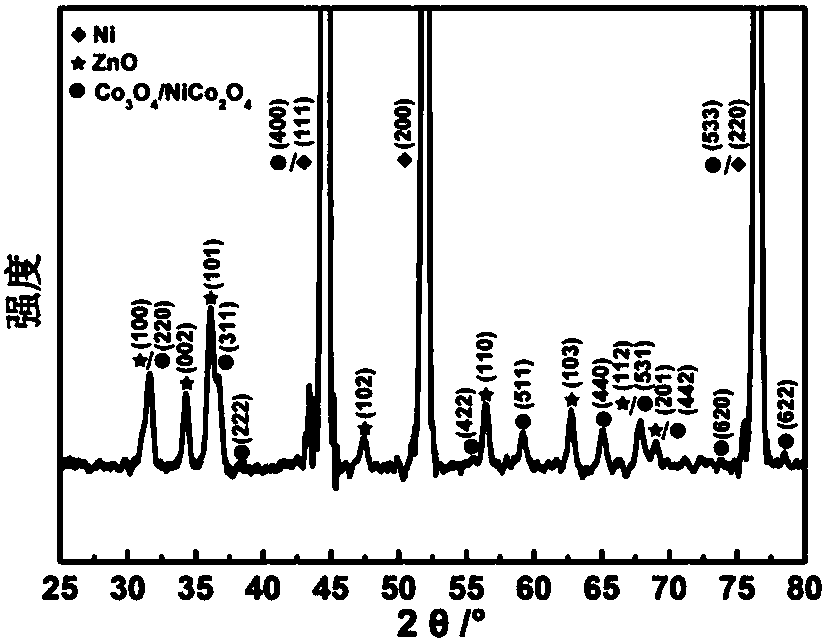

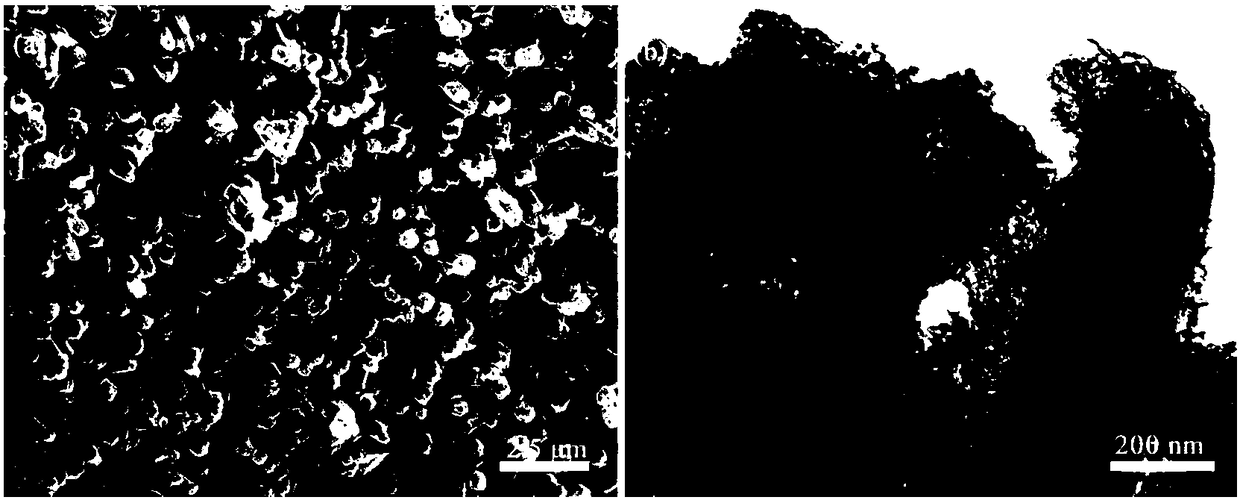

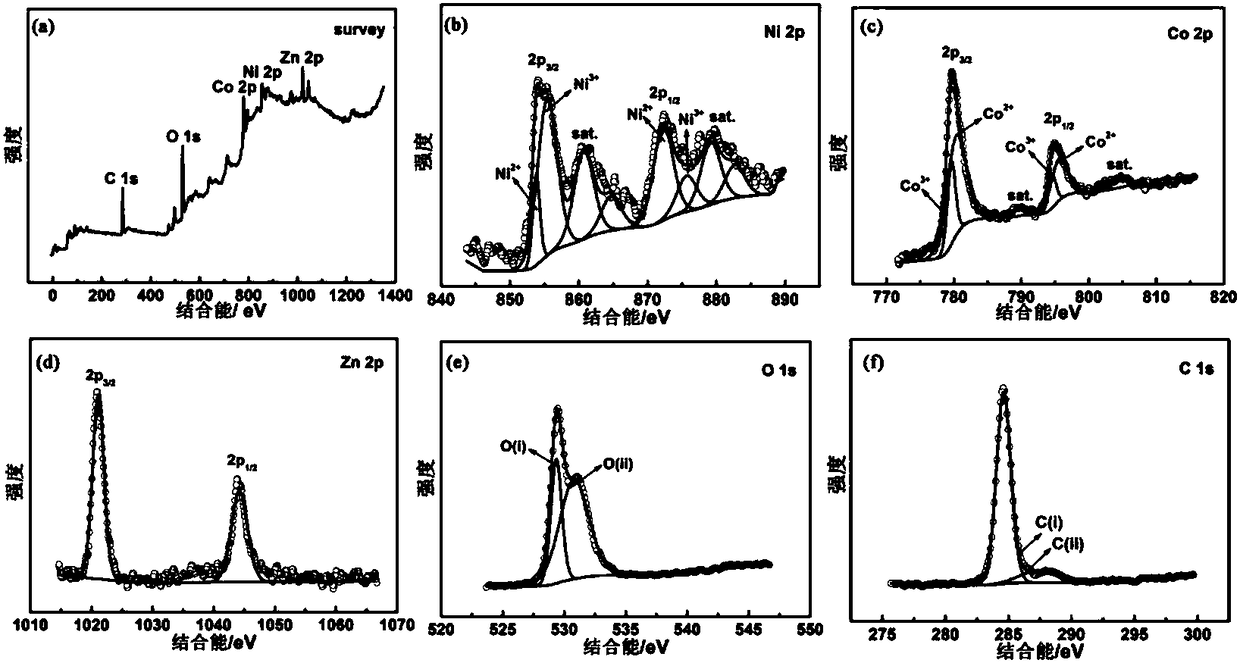

Embodiment 1

[0027] (1) Dissolve 0.29g of zinc nitrate and 0.4g of ammonium nitrate in 1L of distilled water, heat it to 75°C as the electrolyte of the electrolytic cell, and use the 10×10×1.6 foamed nickel with surface pretreatment as the cathode, platinum as the Anode, at a current density of -0.8mA / cm 2 Under the condition of 1.5h, the nickel foam of the cathode was taken out, and dried at 60°C for 10h to obtain ZnO / nickel foam.

[0028] (2) Dissolve 1mmol of cobalt nitrate in 25mL of methanol solution to prepare a uniform solution A, dissolve 4mmol of 2-methylimidazole in 25mL of methanol solution to prepare a uniform solution B, pour B slowly and stir solution, mix well.

[0029] (3) Suspend 10×10×1.6 ZnO / nickel foam in the above mixed solution for 24 hours, take it out, wash it with distilled water and absolute ethanol, and dry it at 60°C for 10 hours to obtain ZnO / ZIFs / nickel foam ;

[0030] (4) Dissolve 4g of nickel nitrate in 1L of ethanol solution to prepare a homogeneous solu...

Embodiment 2

[0041] (1) Dissolve 0.35g of zinc nitrate and 0.5g of ammonium nitrate in 1L of distilled water, heat it up to 50°C as the electrolyte of the electrolytic cell, and use 10×10×1.6 nickel foam with surface pretreatment as the cathode and platinum as the Anode, at a current density of -0.7mA / cm 2 Under the conditions of electrolysis for 2 hours, take out the nickel foam of the cathode, and dry it for 8 hours at 50° C. to obtain ZnO / nickel foam.

[0042] (2) Dissolve 2mmol of cobalt chloride in 50mL of methanol solution to prepare solution A, dissolve 5mmol of 2-methylimidazole in 50mL of methanol solution to prepare solution B, and slowly pour solution B into the stirred solution of A , mixed evenly; hang 10×10×1.6 ZnO / nickel foam in the above mixed solution for 12 hours, take it out, wash it with distilled water and absolute ethanol, and dry it at 40°C for 6 hours to obtain ZnO / ZIFs / foam Nickel: Nickel nitrate is dissolved in a certain amount of ethanol solution to prepare a so...

Embodiment 3

[0046] (1) Dissolve 0.20g of zinc nitrate and 0.6g of ammonium nitrate in 1L of distilled water as the electrolyte of the electrolytic cell, heat it to 95°C, use the surface pretreated 10×10×1.6 foamed nickel as the cathode, and platinum as the Anode, at a current density of -0.9mA / cm 2 Under the conditions of electrolysis for 1 hour, take out the nickel foam of the cathode, and dry it for 12 hours at 80° C. to obtain ZnO / nickel foam.

[0047] (2) 3mmol of cobalt acetate was dissolved in 50mL of methanol solution to prepare solution A, 6mmol of 2-methylimidazole was dissolved in 50mL of methanol solution to prepare solution B, and solution B was slowly poured into the stirred solution of A, Mix evenly; 10×10×1.6mm of ZnO / nickel foam is suspended and placed in the above mixed solution for 36 hours, taken out, washed with distilled water and absolute ethanol, and dried at 80°C for 12 hours to obtain ZnO / ZIFs / nickel foam Dissolve nickel nitrate in a certain amount of ethanol sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com