Method for increasing organic polymer solar cell efficiency

A technology of solar cells and polymers, which is applied in the field of excitons and solar photovoltaics, can solve the problems of low efficiency of organic polymer solar cells, and achieve the effects of increased yield, improved efficiency, and increased light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

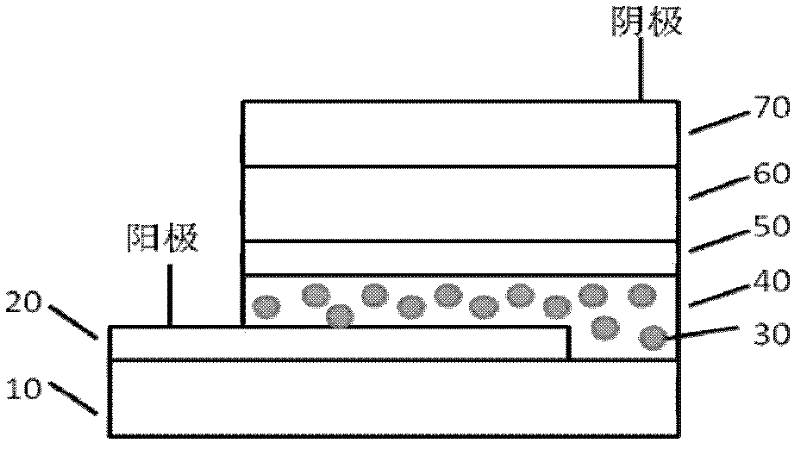

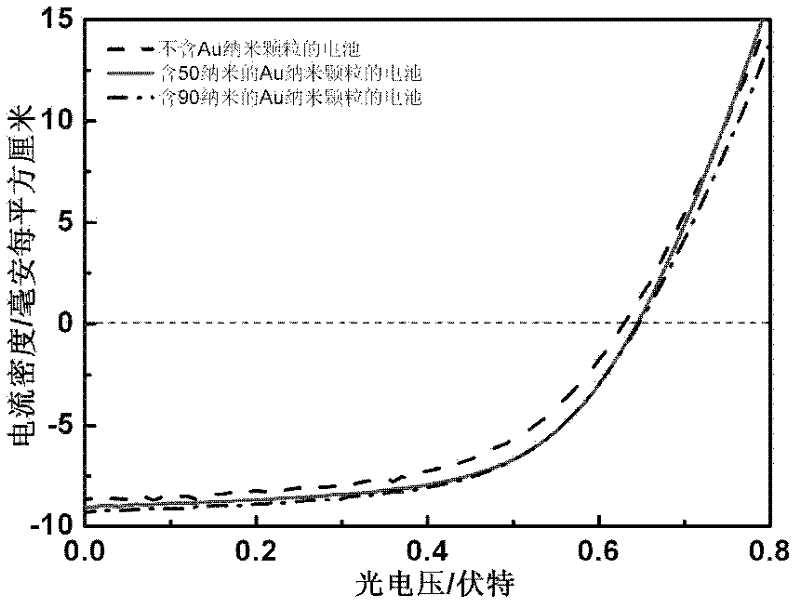

[0046] Embodiment 1: see figure 1As shown, the patterned ITO 20 / glass 10 substrate was cleaned with an organic reagent, and the sheet resistance of the ITO 20 was 15 ohms / square. A PEDOT:PSS 40 layer was prepared on the ITO 20 / glass 10 substrate, and the thickness of the PEDOT:PSS 40 layer was 30nm. A layer of PEDOT:PSS 50 was prepared on the PEDOT:PSS 40 layer, and the thickness of the PEDOT:PSS 50 layer was 20 nm. The PEDOT:PSS 40 and 50 layers on one side are erased until the surface of the ITO 20 is exposed, so that the original PEDOT:PSS 40 and 50 layers form a mesa. On PEDOT:PSS 50 layers, spin-coat one deck P3HT:PCBM blend film 60, the mass concentration of P3HT is 10mg / ml, is solvent with chlorobenzene, the mass ratio of P3HT and PCBM is 1: 1, the P3HT of spin coating: The thickness of the PCBM blend film 60 is 100 nm. A layer of Al electrode 70 is deposited on the P3HT:PCBM blend film 60 by using thermal evaporation technology, and the thickness of the Al electrode...

Embodiment 2

[0047] Embodiment 2: see figure 1 As shown, the patterned ITO 20 / glass 10 substrate was cleaned with an organic reagent, and the sheet resistance of the ITO 20 was 15 ohms / square. A layer of PEDOT:PSS 40 containing Au nanoparticles 30 was prepared on the ITO 20 / glass 10 substrate. The diameter of the Au nanoparticles 30 was 50 nm, and the thickness of the PEDOT:PSS 40 layer was 30 nm. A thin layer of PEDOT:PSS 50 was prepared on the PEDOT:PSS 40 layer, and the thickness of the PEDOT:PSS 50 layer was 20 nm. The PEDOT:PSS 40 and 50 layers on one side are erased until the surface of the ITO 20 is exposed, so that the original PEDOT:PSS 40 and 50 layers form a mesa. On PEDOT:PSS 50 layers, spin-coat one deck P3HT:PCBM blend film 60, the mass concentration of P3HT is 10mg / ml, is solvent with chlorobenzene, the mass ratio of P3HT and PCBM is 1: 1, the P3HT of spin coating: The thickness of the PCBM blend film 60 is 100 nm. A layer of Al electrode 70 is deposited on the P3HT:PCBM ...

Embodiment 3

[0048] Embodiment 3: see figure 1 As shown, the patterned ITO 20 / glass 10 substrate was cleaned with an organic reagent, and the sheet resistance of the ITO 20 was 15 ohms / square. A layer of PEDOT:PSS 40 containing Au nanoparticles 30 was prepared on the ITO 20 / glass 10 substrate. The diameter of the Au nanoparticles 30 was 90 nm, and the thickness of the PEDOT:PSS 40 layer was 30 nm. A layer of PEDOT:PSS 50 was prepared on the PEDOT:PSS 40 layer, and the thickness of the PEDOT:PSS 50 layer was 20 nm. The PEDOT:PSS 40 and 50 layers on one side are erased until the surface of the ITO 20 is exposed, so that the original PEDOT:PSS 40 and 50 layers form a mesa. On PEDOT:PSS 50 layers, spin-coat one deck P3HT:PCBM blend film 60, the mass concentration of P3HT is 10mg / ml, is solvent with chlorobenzene, the mass ratio of P3HT and PCBM is 1: 1, the P3HT of spin coating: The thickness of the PCBM blend film 60 is 100 nm. A layer of Al electrode 70 is deposited on the P3HT:PCBM blend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com