Silicon heterojunction/perovskite based double-electrode laminated solar cell

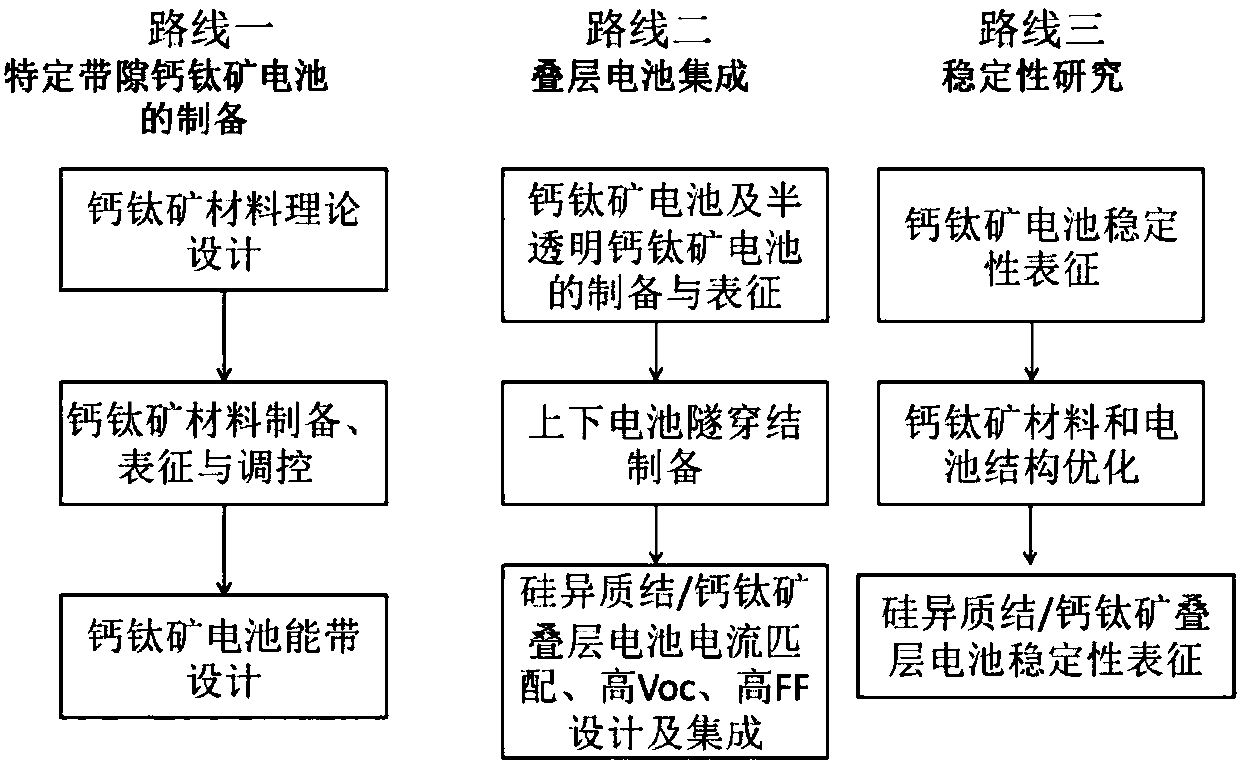

A solar cell and silicon heterojunction technology, applied in the field of solar cells, can solve the problems of restricting cell performance, weak perovskite spectral response, and large band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

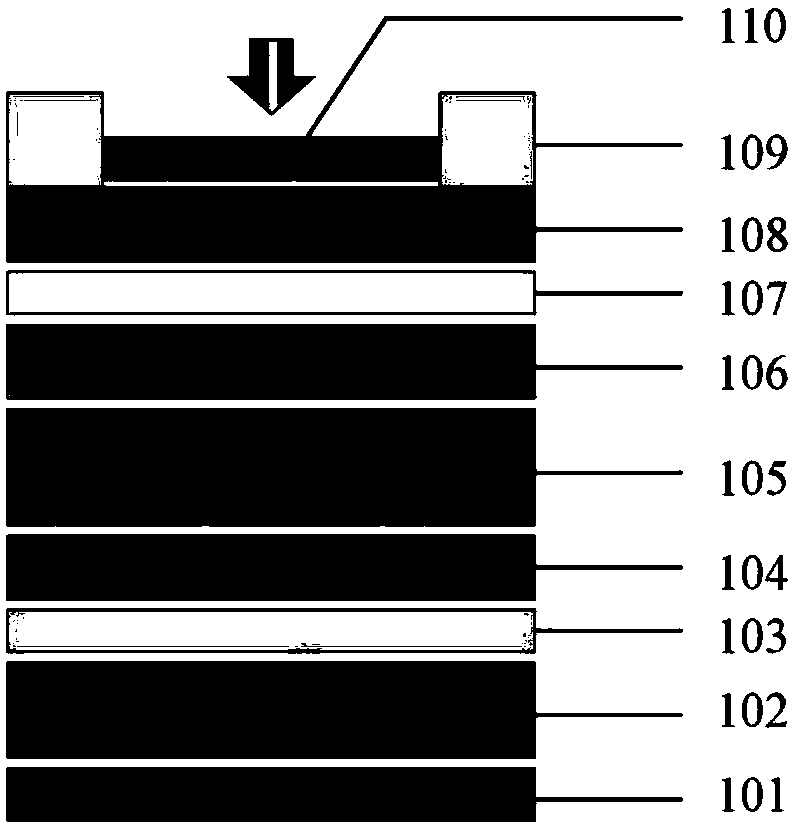

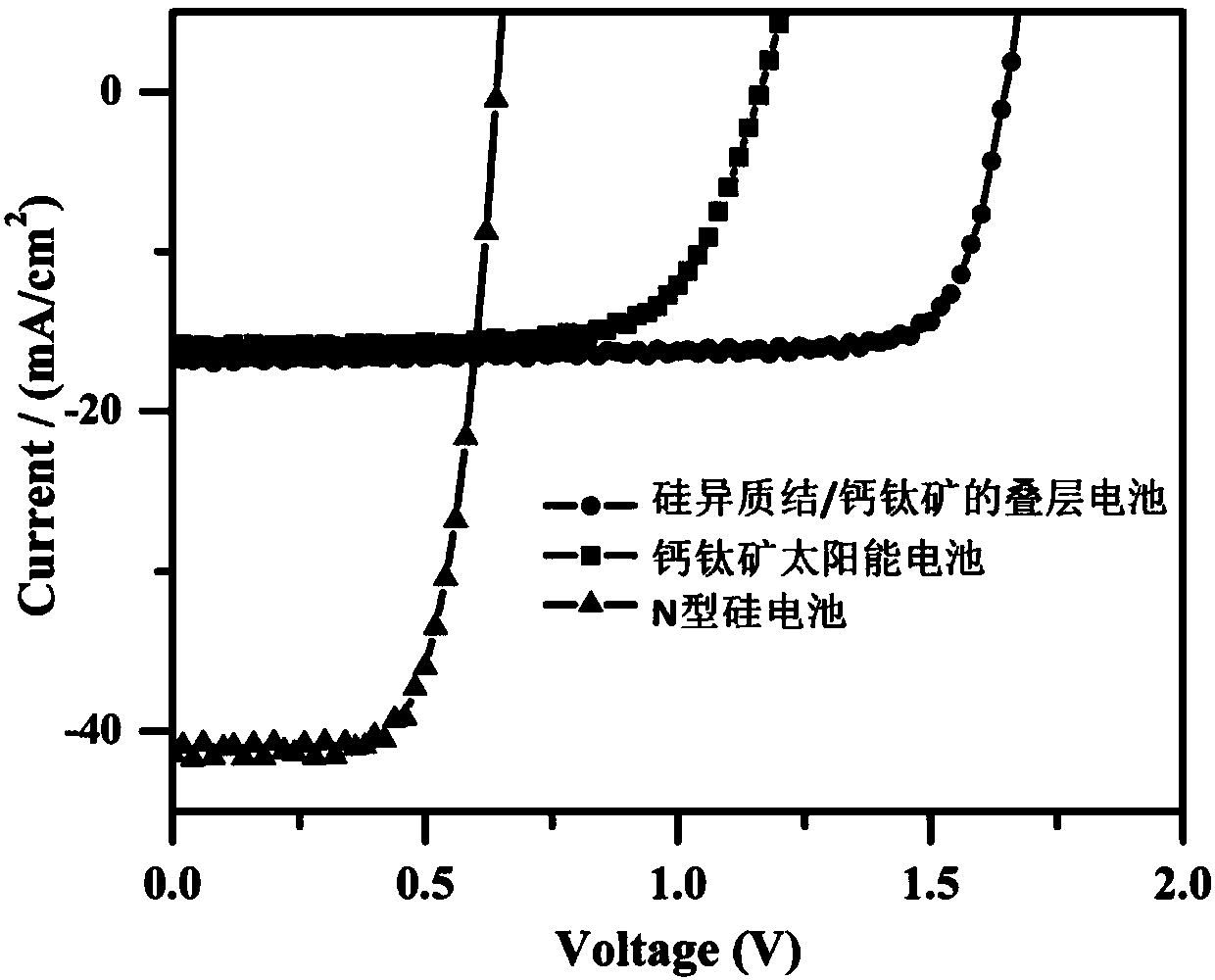

[0030] Embodiment 1 (stack efficiency optimization based on different perovskite bandgap widths)

[0031] (1) Commercialized n-type heterojunction Si cells with a size of 1cm*1cm;

[0032] (2) Magnetron sputtering power 80nm ITO film is used as the connecting layer of the upper and lower batteries on the Si battery;

[0033] (3) The Si battery after sputtering is ultrasonicated with ethanol solution for 10 minutes, dried with a nitrogen gun, and then used with a UV cleaning machine for 20 minutes to increase the wettability of the solution and remove organic matter on the surface;

[0034] (4) Preparation of electron transport layer: SnO 2 2H 2 O (purchased from Alfa Aesar) is spin-coated on the Si substrate, spin-coated with a homogenizer at 3000rpm*30s, and then annealed at 150°C for 30min to form dense SnO 2 Thin film; annealed at 3000rpm150℃ for 30min.

[0035] (5) For the preparation of perovskite absorbing layers with different band gaps, first configure the precurso...

Embodiment 2

[0042] Embodiment 2 (optimizing the electron transport layer)

[0043] This embodiment provides a method for preparing a perovskite solar cell. The preparation method provided in this embodiment three is basically the same as that of embodiment one, except that the spin-coated electron transport layer in step (4) of embodiment one is The rotation speed was changed, and then the thickness of the tin dioxide layer was changed, and a composite electron transport layer (composite of titanium dioxide and tin dioxide) was tried, so that the electron transport layer could be used to modify the surface fluctuation of the Si battery to reduce the Its roughness provides a good environment for the growth of the upper layer of perovskite, and improves the extraction efficiency of photogenerated electrons, avoiding the impact of charge accumulation on the life of the device.

[0044] Table 2 Effect of regulation of electron transport layer on device performance

[0045]

Embodiment 3

[0046] Embodiment three (exploring whether magnesium fluoride can improve the efficiency of the battery)

[0047] (1) The etched ITO glass has a size of 1.5cm*1.5cm. The transparent conductive glass is washed and cleaned by the traditional substrate cleaning process.

[0048] (2) After drying with a nitrogen gun, use a UV cleaning machine for 20 minutes to increase the wettability of the solution and remove organic matter on the surface;

[0049] (3) Step (4) with the above-mentioned implementation case one;

[0050] (4) The preparation of the perovskite absorbing layer, first configure the precursor of two-step spin coating, dissolve 230mg lead iodide and 150mg lead bromide in 1ml N, N dimethylformamide (DMF) solvent, 70 °C and stirred for 5 hours. Spread 35ul of the precursor solution on the substrate, spin dry at 3000rpm*30s, and anneal at 70°C for 20min to form a bright yellow film. Dissolve 40mg of methyl iodide and 20 mg of methyl iodide in 1ml of isopropanol, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com