Method of improving perovskite solar cell efficiency by using ionic liquid additive

A technology for solar cells and ionic liquids, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficult volatilization and device performance degradation, and achieve the effects of low cost, reduced roughness, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

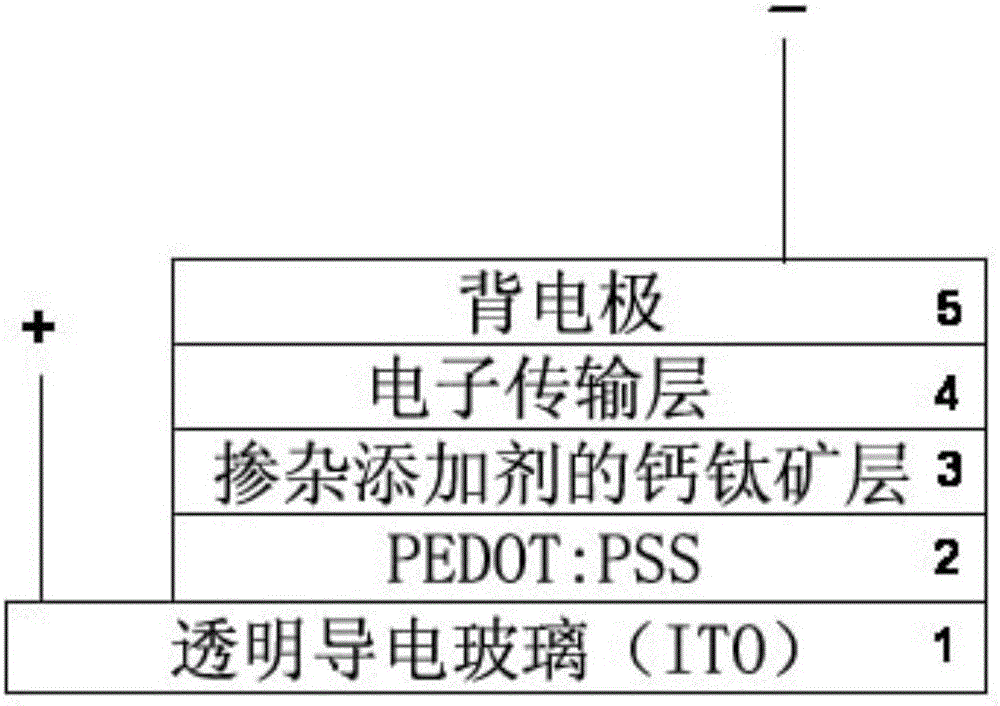

[0036] A method for improving the efficiency of perovskite solar cells by using ionic liquid additives, comprising the following processes:

[0037] (1) Preparation of precursor mixed solution

[0038] The molar ratio of lead acetate and methyl iodide is 1:3, and the ratio of lead acetate and methyl iodide is 2.5:1N,N-dimethylformamide molar ratio, and dissolved in N,N-dimethylformamide solution to form mixed solution; adding 1-ethylpyridinium chloride ionic liquid with a mass fraction of 1wt% as an additive to form a precursor mixed solution;

[0039] (2) Preparation of perovskite thin films

[0040] The precursor mixed solution was left standing at room temperature for 1 hour, spin-coated at 2000 rpm to form a film on a conductive glass substrate with PEDOT:PSS, and annealed on a hot stage at 90°C for 50 minutes to obtain a perovskite film;

[0041] (3) Deposition of electron transport layer

[0042] The electron transport layer is deposited on the surface of the perovskite...

Embodiment 2

[0046] A method for improving the efficiency of perovskite solar cells by using ionic liquid additives, comprising the following processes:

[0047] (1) Preparation of precursor mixed solution

[0048] The molar ratio of lead acetate and methyl iodide is 1:3, and the ratio of lead acetate and methyl iodide is 1.5:1 N,N-dimethylformamide molar ratio, and dissolved in N,N-dimethylformamide solution to form mixed solution; adding 1-ethylpyridinium chloride ionic liquid with a mass fraction of 3wt% as an additive to form a precursor mixed solution;

[0049] (2) Preparation of perovskite thin films

[0050] The precursor mixed solution was left standing at room temperature for 1 hour, spin-coated at 2000rpm on a conductive glass substrate with PEDOT:PSS, and annealed on a hot stage at 90°C for 30 minutes to obtain a perovskite film;

[0051] (3) Deposition of electron transport layer

[0052] The electron transport layer is deposited on the perovskite film by solution spin coati...

Embodiment 3

[0056] A method for improving the efficiency of perovskite solar cells using ionic liquid additives. It includes the following steps:

[0057] (1) Soak the corroded ITO conductive glass with detergent for 3-4 hours. Then ultrasonically clean in an ultrasonic cleaner for 15 minutes, then scrub with wet cotton, and finally rinse with ultrapure water. Dry the washed ITO substrate under an infrared lamp, and then use ultraviolet ozone (UV / O 3 ) after 15 minutes of processing, take it out for later use.

[0058] (2) Spin-coat PEDOT:PSS solution on the cleaned ITO glass, spin-coat at 3000rpm for 30s, and anneal at 120°C for 30min.

[0059] (3) Weigh lead acetate and methyl iodide solids with a molar ratio of 1:3, add 1-ethylpyridinium chloride with a mass fraction of 1wt% as an additive, dissolve in 0.5mL of N-dimethylformamide (DMF ) solution. In the atmospheric environment, the precursor solution was allowed to stand at room temperature for 1 h. 160 μL of precursor solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com