Preparation method of organic-inorganic perovskite solar battery

A technology of solar cells and inorganic calcium, which can be used in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as high cost, uncontrollable surface morphology, and limited development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

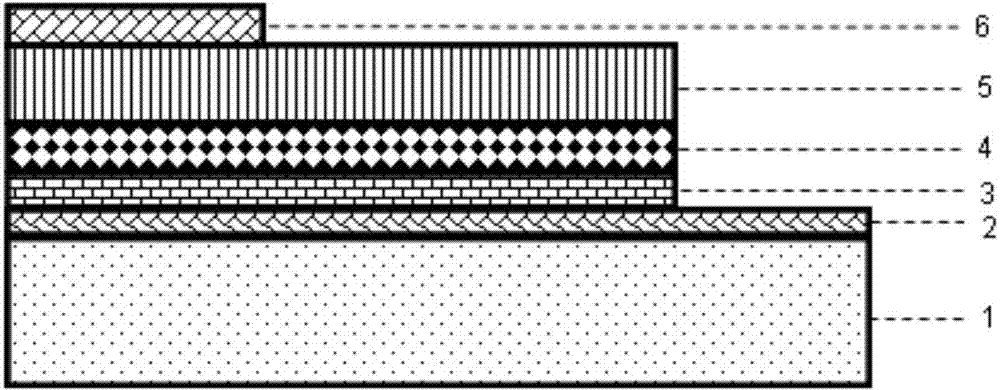

[0050] Example 1 Preparation of planar structure organic-inorganic perovskite solar cells

[0051] (1) Processing and cleaning of AZO glass substrates: Cut the glass substrates into appropriate sizes, then place the glass substrates in acetone, alcohol, and deionized water for 15 minutes, then dry them with pure nitrogen, and immediately use ultraviolet ozone to clean the surface Treat for 12 minutes; (2) Etching of AZO transparent conductive oxide: use pulse laser to etch the pretreated AZO transparent conductive film, then place it in acetone, alcohol, and deionized water for ultrasonic cleaning for 15 minutes, and use Pure nitrogen is blown dry; (3) the preparation of n-type ZnO semiconductor layer: utilize magnetron sputtering method to prepare ZnO thin film on the AZO conductive layer that etches, and magnetron sputtering preparation process is: adopt purity to be 99.99% Zinc oxide ceramic target, the vacuum degree of the vacuum chamber is 1×10 -4 Pa, argon flow rate is ...

Embodiment 2

[0052] Example 2 Preparation of planar structure organic-inorganic perovskite solar cells

[0053] (1) Processing and cleaning of FTO glass substrates: Cut the glass substrates into appropriate sizes, then place the glass substrates in acetone, alcohol, and deionized water for 15 minutes for ultrasonic cleaning, then dry them with pure nitrogen, and immediately use ultraviolet ozone to surface Treat for 12 minutes; (2) Etching of transparent conductive oxide: use 0.1M dilute hydrochloric acid and zinc powder to etch the pretreated FTO transparent conductive film, and then place it in acetone, alcohol, deionized water and ultrasonic Cleaning for 15 minutes, and drying with pure nitrogen; (3) Depositing strontium titanate as an n-type metal oxide semiconductor layer on the pretreated and etched FTO by using a pulsed laser. The preparation process of its strontium titanate n-type layer is as follows: using 99.99% strontium titanate ceramic target, using pulsed laser deposition te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com