Method for improving efficiency and stability of perovskite solar cell, and perovskite solar cell

A solar cell, perovskite technology, used in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

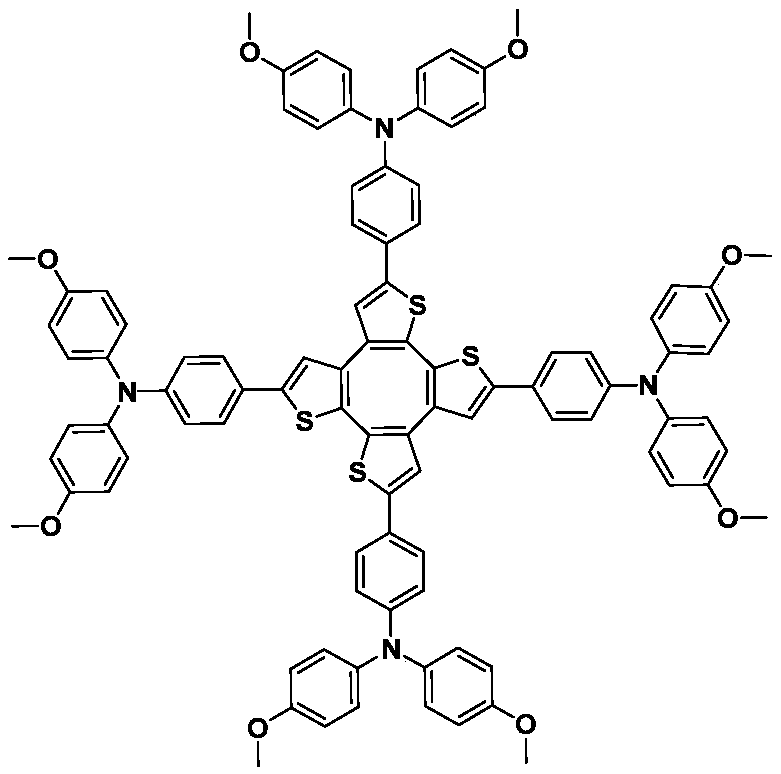

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

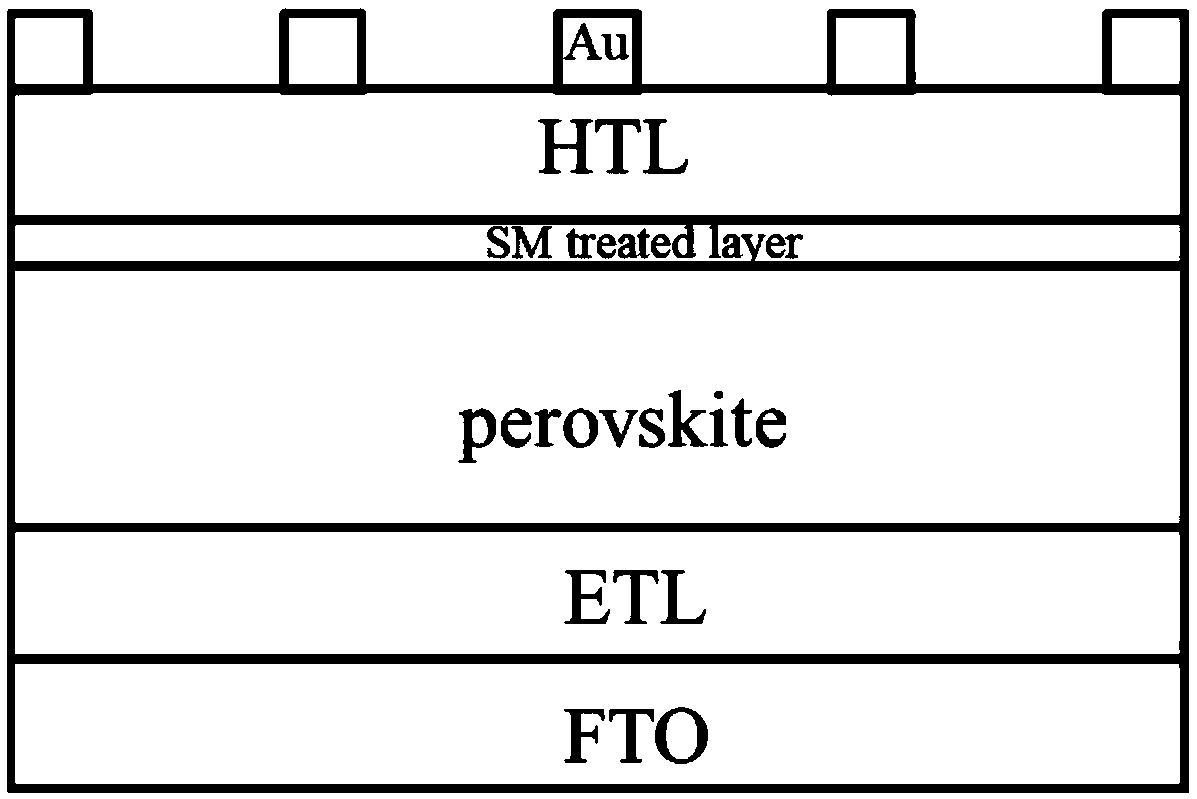

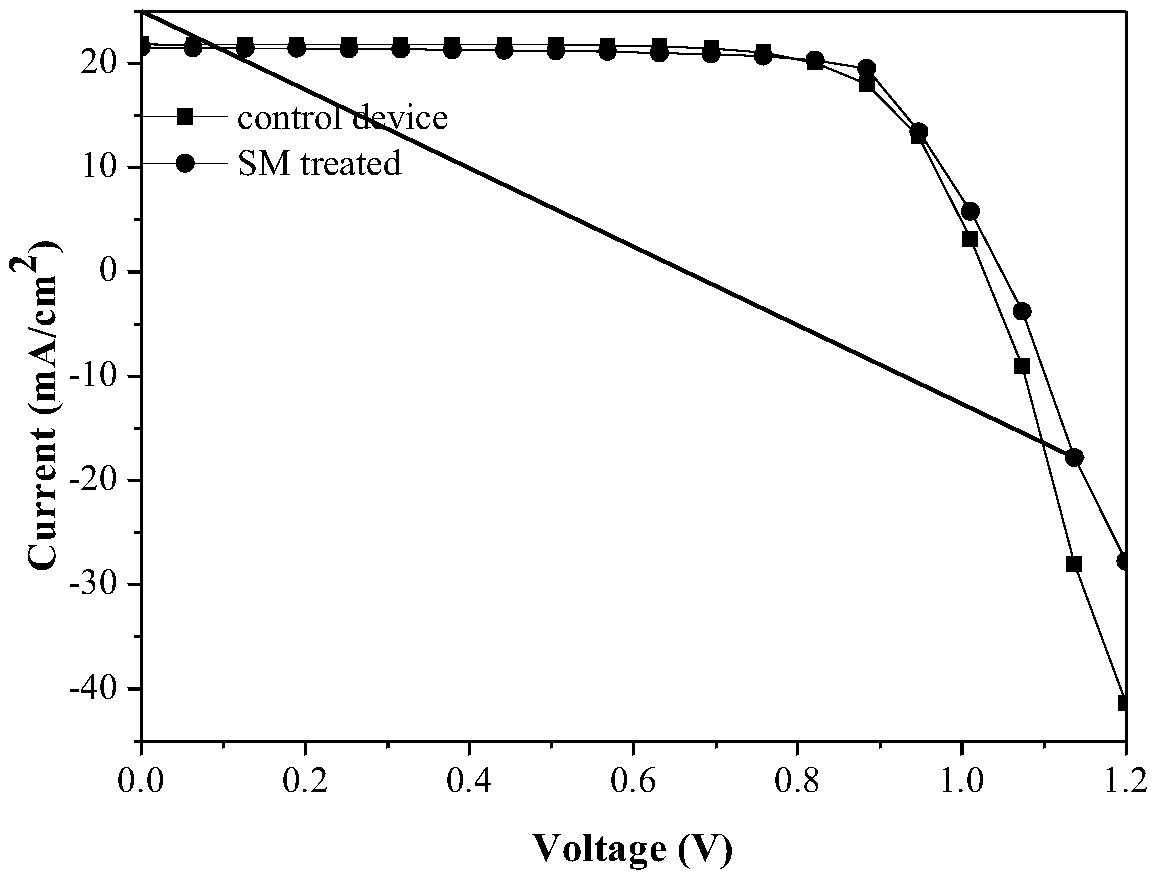

[0034] First, the FTO glass substrate was ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, followed by UV-ozone treatment for 20 minutes. Dilute 1 mL of titanium(IV) isopropoxide in 10 mL of ethanol, spin-coat on FTO at a rate of 6000 rpm for 30 s to prepare a dense layer (bl-TiO2), and then anneal at 450 ° C in air for 20 min. Dissolve commercially available paste (30NR-D, Dyesol) in ethanol (150 mg / mL) at 4000 rpm to prepare mesoporous TiO 2 (mp-TiO 2 ) layer, annealed in air at 450°C for 20 minutes to remove the organic part. Prepare the precursor solution (CsPbI 3 ) 0.05 (FAPbI 3 ) 0.79 (MAPbBr 3 ) 0.16, to deposit the perovskite layer in a two-step method, that is, drop 40 microliters of perovskite solution on the substrate, spin-coat at 1000rpm for 10s, and then spin-coat at 6000rpm for 20s, before the end of the second step of spin-coating 110 microliters of chlorobenzene solution containing α,β-COTh-OMeTAD (1mg / ml) was quickly ...

Embodiment 2

[0036] First, the FTO glass substrate was ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, followed by UV-ozone treatment for 20 minutes. Dilute 1 mL of titanium(IV) isopropoxide in 10 mL of ethanol, spin-coat on FTO at a rate of 6000 rpm for 30 s to prepare a dense layer (bl-TiO2), and then anneal at 450 ° C in air for 20 min. Dissolve commercially available paste (30NR-D, Dyesol) in ethanol (150 mg / mL) at 4000 rpm to prepare mesoporous TiO 2 (mp-TiO 2 ) layer, annealed in air at 450°C for 20 minutes to remove the organic part. Prepare the precursor solution (CsPbI 3 ) 0.05 (FAPbI 3 ) 0.79 (MAPbBr 3 ) 0.16 , to deposit the perovskite layer in a two-step method, that is, drop 50 microliters of the perovskite solution on the substrate, spin-coat at 1000rpm for 10s, then spin-coat at 6000rpm for 20 seconds, and finish the spin-coating in the second step In the first 5 seconds, 100 microliters of CB solution containing α,β-COTh-OMeTAD (1m...

Embodiment 3

[0037] Embodiment 3 (comparative example)

[0038] This embodiment is a positive structure device without small molecule passivation. The specific method is as follows: firstly, the FTO glass substrate is ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, and then UV-ozone treatment is performed for 20 minutes. Dilute 1 mL of titanium(IV) isopropoxide in 10 mL of ethanol, spin-coat on FTO at a rate of 6000 rpm for 30 s to prepare a dense layer (bl-TiO2), and then anneal at 450 ° C in air for 20 min. Dissolve commercially available paste (30NR-D, Dyesol) in ethanol (150 mg / mL) at 4000 rpm to prepare mesoporous TiO 2 (mp-TiO 2 ) layer, annealed in air at 450°C for 20 minutes to remove the organic part. Prepare the precursor solution (CsPbI 3 ) 0.05 (FAPbI 3 ) 0.79 (MAPbBr 3 ) 0.16 , to deposit the perovskite layer in a two-step method, that is, drop the perovskite solution on the substrate, spin-coat at 1000rpm for 10s, and then spin-coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com