Method for modifying aramid fiber by using carbon nano tubes

A technology of carbon nanotube modification and aramid fiber, which is applied in fiber type, fiber treatment, textiles and papermaking, etc., can solve the problems of fiber surface damage and mechanical property degradation, and achieve the improvement of mechanical properties, improve bonding performance, The effect of overcoming mechanical property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

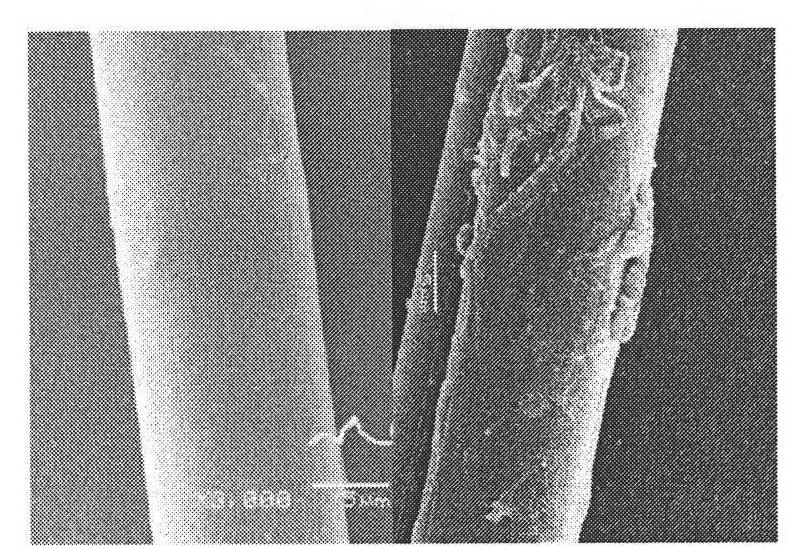

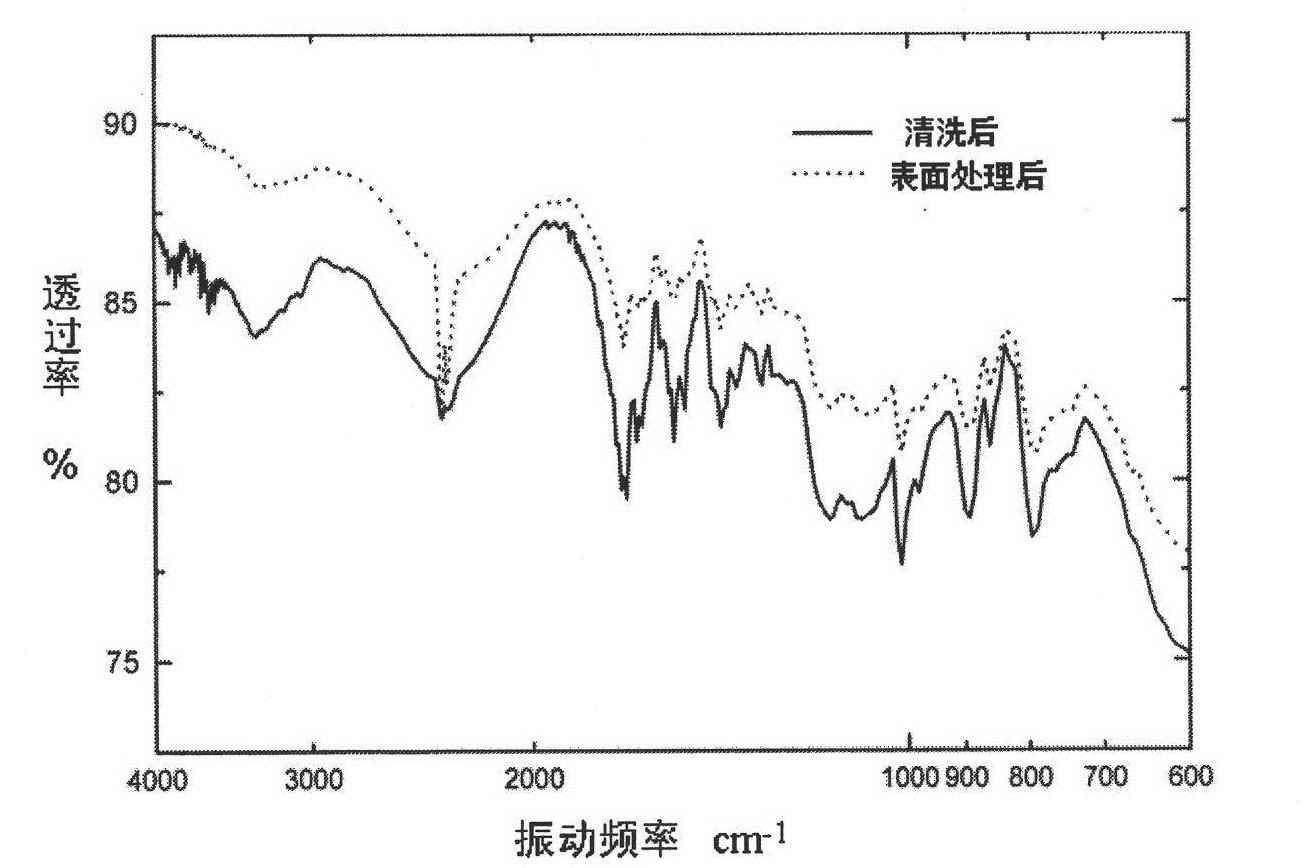

[0022] 1. Surface treatment of Kevlar fiber:

[0023] Wrap 20-50cm Kevlar fibers on a self-made glass frame, and successively use dichloroethane, water, and absolute ethanol for heating and boiling extraction for 0.5-1 h, remove the treatment agent on the fiber surface, and vacuum dry for use.

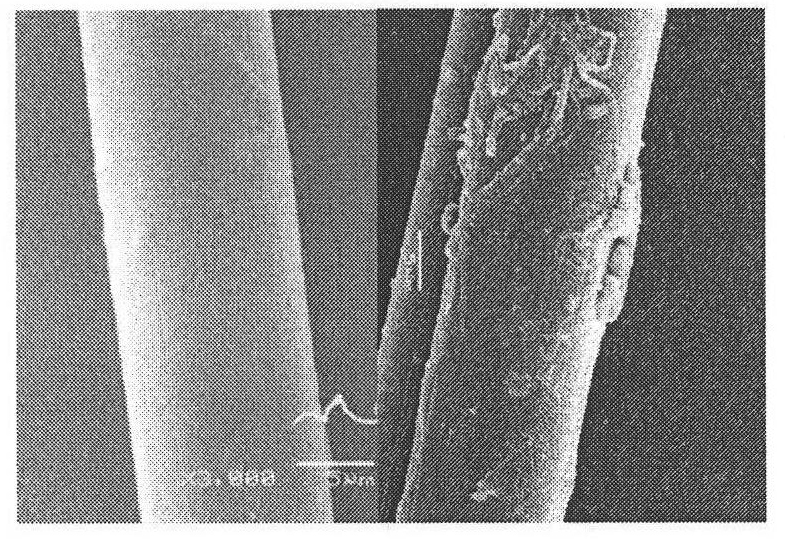

[0024] 2. Surface treatment of carbon nanotubes:

[0025] The carbon nanotubes are placed in a mixed solution of 98% concentrated sulfuric acid and 70% nitric acid in a ratio of 1 to 3:1. After 4 to 10 hours of ultrasonic-assisted stirring, add water to dilute, and let stand overnight to fully precipitate the carbon nanotubes. Pour the upper layer of liquid, dilute the bottom residue with deionized water and vacuum filter with a 10-50um pore size polytetrafluoroethylene membrane, rinse the filtrate repeatedly with deionized water until the filtrate is nearly neutral, and vacuum dry for use.

[0026] 3. Amination of Kevlar fiber surface:

[0027] Prepare a mixed solution of 1,4-diazab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com