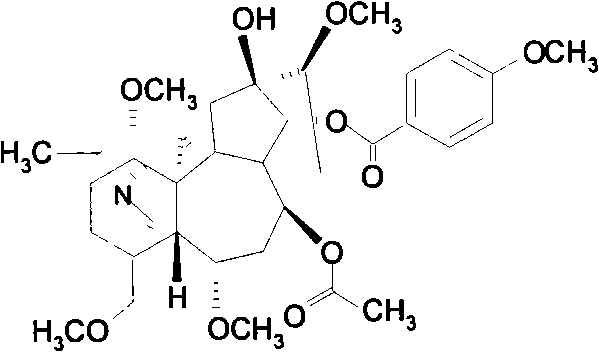

Preparation method of high purity bulleyaconitine A

A high-purity technology of aconitin, applied in antipyretics, nervous system diseases, organic chemistry, etc., can solve the problems of high production cost, low content, and difficulty in industrialized large-scale production, and achieve low production cost and high product purity High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

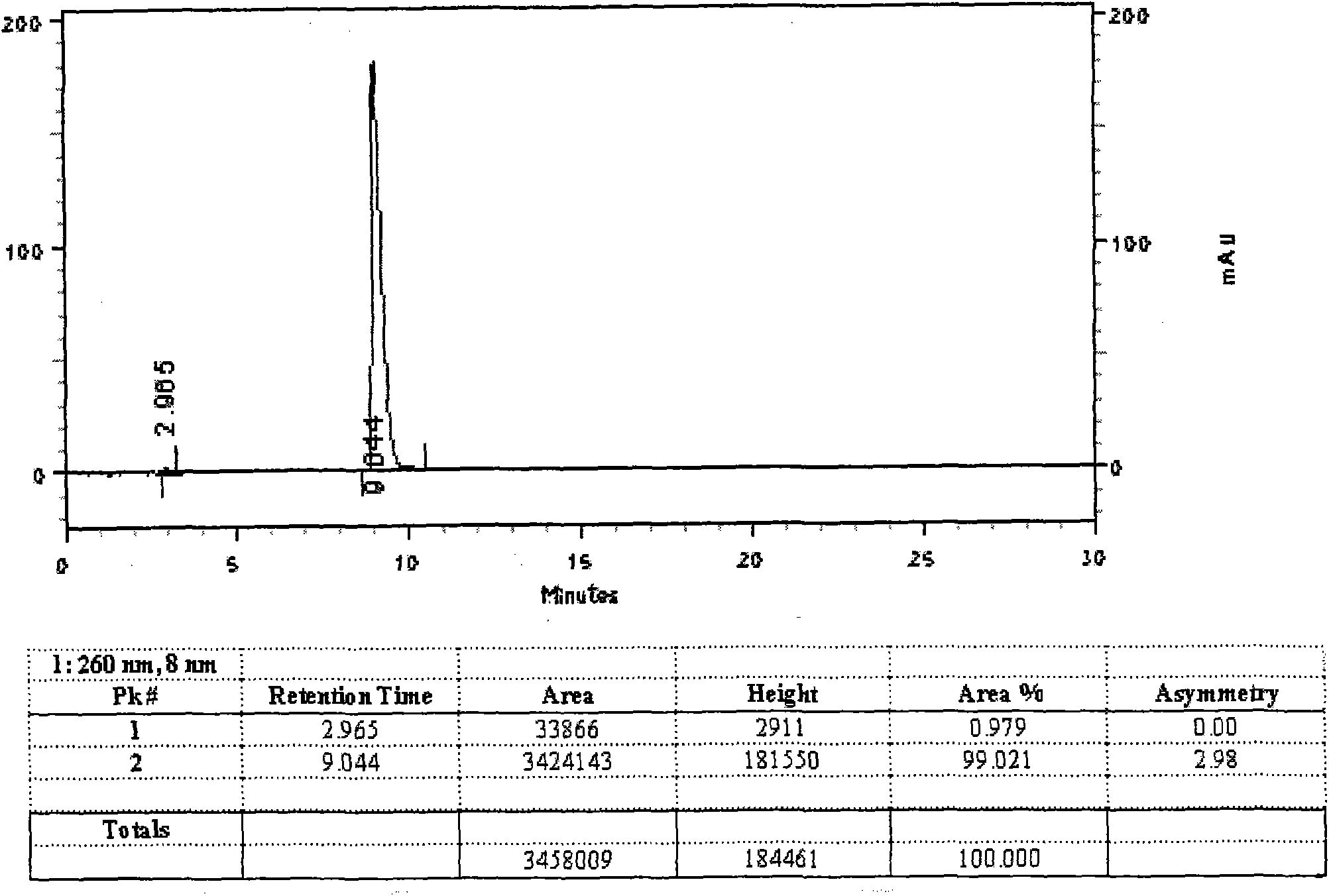

Image

Examples

Embodiment 1

[0031] Get 1kg of Aconiti officinalis root tuber cleanly selected and crushed into coarse powder, use 0.5% hydrochloric acid and 75% methanol aqueous solution as the extraction solvent, soak for 12 hours, and reflux extraction for 3 times, each time for 3 hours, the volume-weight ratio of the amount of extraction solvent to the medicinal material The ratio is 6:1. Concentrate under reduced pressure at 80°C until there is no alcohol, cool to room temperature, make the relative density about 1.10, pH 2.0-3.0, let it stand for 12 hours, and filter to obtain the acidic water extract. Adjust the pH of the obtained acid water extract to 7.0±0.5 with ammonia water, and extract with ethyl acetate whose volume ratio between the acid water liquid and the extraction solvent is 1:3 each time, and extract three times. Concentrate and recover the extraction solvent to obtain an ethyl acetate extraction paste. The obtained extraction paste was eluted with silica gel for column chromatography...

Embodiment 2

[0034] Take 1kg of Aconiti officinalis root tubers and grind them into coarse powder, use 0.7% hydrochloric acid and 95% ethanol aqueous solution as the extraction solvent, soak for 24 to 48 hours, and percolate at a rate of 5ml / min.kg. The ratio of volume to medicinal material weight is 30:1. Concentrate the percolation solution at 80°C under reduced pressure to no alcohol, cool to room temperature, make the relative density 1.10, pH 1.0-3.0, let stand for 18 hours, filter to obtain acid water extract. Adjust the pH of the obtained acid water extract to 7.0±0.5 with 1 mol / L sodium hydroxide aqueous solution, and extract with chloroform with a volume ratio of acid water and extraction solvent of 1:5 each time, and extract 4 times. Concentrate and recover the extraction solvent to obtain a chloroform extraction paste. The obtained extraction paste is eluted with a weight ratio of 1:50 column chromatography with alumina as a filler, and the cyclohexane-acetone-diethylamine syst...

Embodiment 3

[0037] Take 1kg of Aconiti officinalis root tubers, cleanly select and crush them into coarse powder, use 1.0% hydrochloric acid and 75% isopropanol aqueous solution as extraction solvent, soak for 24 to 48 hours, and percolate at a percolation rate of 3ml / min.kg. The ratio of the total volume of the roller to the weight of the medicinal material is 30:1. Concentrate the percolation liquid at 90°C under reduced pressure to no alcohol, cool to room temperature, make the relative density 1.15, pH 1.5-3.0, let stand for 20 hours, filter to obtain acid water extract. The obtained acid water extract was adjusted to pH 8.0 ± 0.5 with 1 mol / L potassium hydroxide aqueous solution, extracted with chloroform each time with a volume ratio of acid water and extraction solvent of 1:4, and extracted 4 times. Concentrate and recover the extraction solvent to obtain an ethyl acetate extraction paste. The obtained extraction paste was eluted with silica gel for column chromatography with a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com