Uvioresistant, antibacterial and flame retardant terylene fiber, preparation method and application thereof

A flame-retardant polyester and anti-ultraviolet technology, applied in the field of polyester fiber, to achieve the effects of improved dispersion, improved spinnability, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

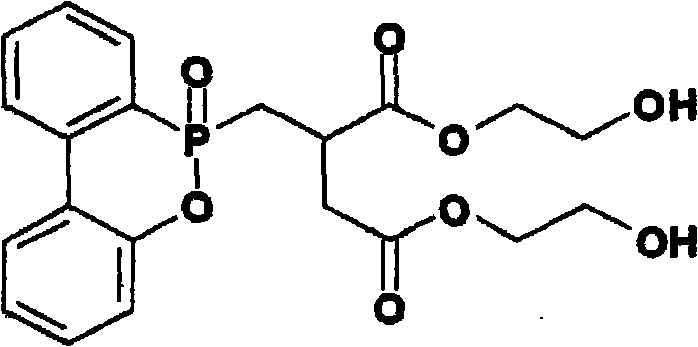

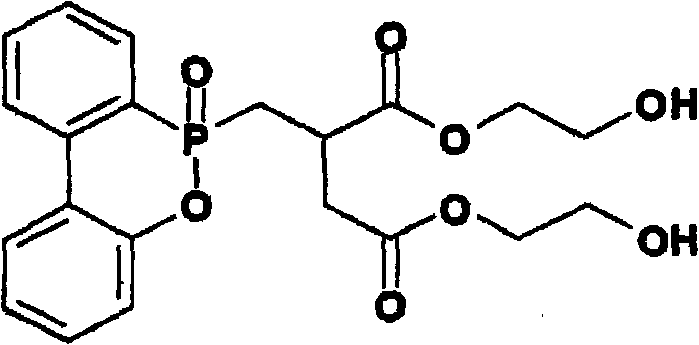

Image

Examples

Embodiment 1

[0023] 1. An anti-ultraviolet, antibacterial, and flame-retardant polyester fiber, which is composed of the following raw materials: 10 kg of silver-based antibacterial masterbatch, 10 kg of anti-ultraviolet masterbatch, and 980 kg of copolymerized phosphorus-based flame-retardant polyester fiber-forming resin.

[0024] 2. Preparation of anti-ultraviolet, antibacterial and flame-retardant polyester fibers:

[0025] (1) Get 10% by weight of nano-silver ions and nano-carrier silicon dioxide and 90% by weight of polyethylene terephthalate blend, extrude with a screw extruder, pelletize, and make silver It is an antibacterial masterbatch, ready for use, wherein the blending temperature is 250°C, and the screw speed is 100rpm;

[0026] (2) take the anti-ultraviolet agent of 10% by weight and the polyethylene terephthalate of 90% by weight, blend, extrude with screw extruder, pelletize, make anti-ultraviolet masterbatch, Standby, wherein the blending temperature is 250°C, and the s...

Embodiment 2

[0040] 1. An anti-ultraviolet, antibacterial and flame-retardant polyester fiber, which is composed of the following raw materials: 100 kg of silver-based antibacterial masterbatch, 50 kg of anti-ultraviolet masterbatch, and 850 kg of copolymerized phosphorus-based flame-retardant polyester fiber-forming resin.

[0041] 2. Preparation of anti-ultraviolet, antibacterial and flame-retardant polyester fibers:

[0042] (1) Get 30% by weight of nano-silver ions and nano-carrier zirconium phosphate to blend with 70% by weight of polyethylene terephthalate, extrude with a screw extruder, and pelletize to obtain silver-based Antibacterial masterbatch, spare, wherein the blending temperature is 270°C, and the screw speed is 190rpm;

[0043] (2) take the anti-ultraviolet agent of 30% by weight and the polyethylene terephthalate of 70% by weight, blend, extrude with screw extruder, pelletize, make anti-ultraviolet masterbatch, Standby, wherein the blending temperature is 270°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| coefficient of variation of linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com