Method of preparing organic/inorganic hybridization reactivity semi-interpenetrating network structure emulsion

An interpenetrating network, inorganic technology, applied in the field of preparation of organic/inorganic hybrid reactive semi-interpenetrating network structure emulsion, can solve the problem of coating hardness, water resistance, anti-stickiness, chemical resistance, and mutual Problems such as limited improvement in performance of through-the-network coating films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

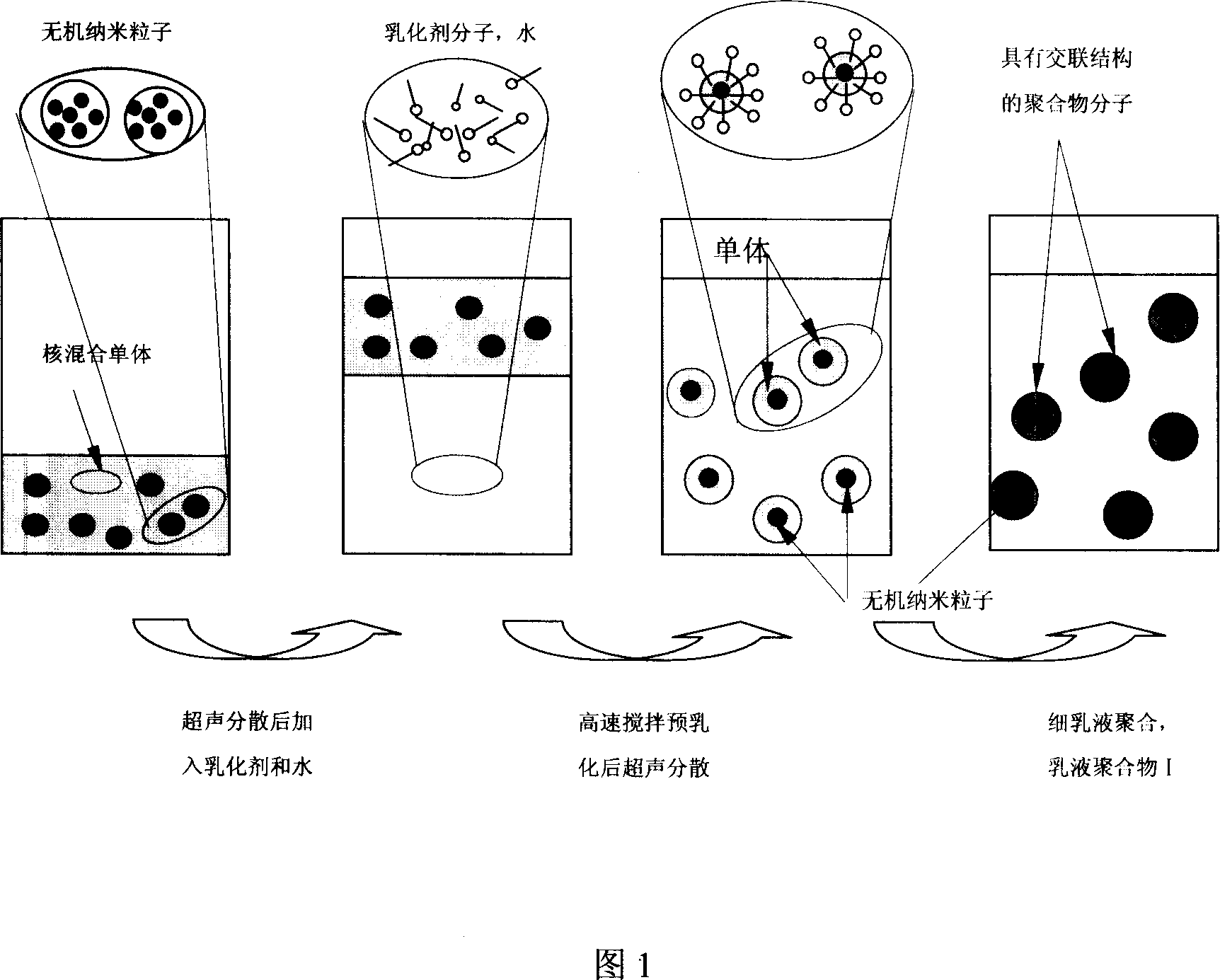

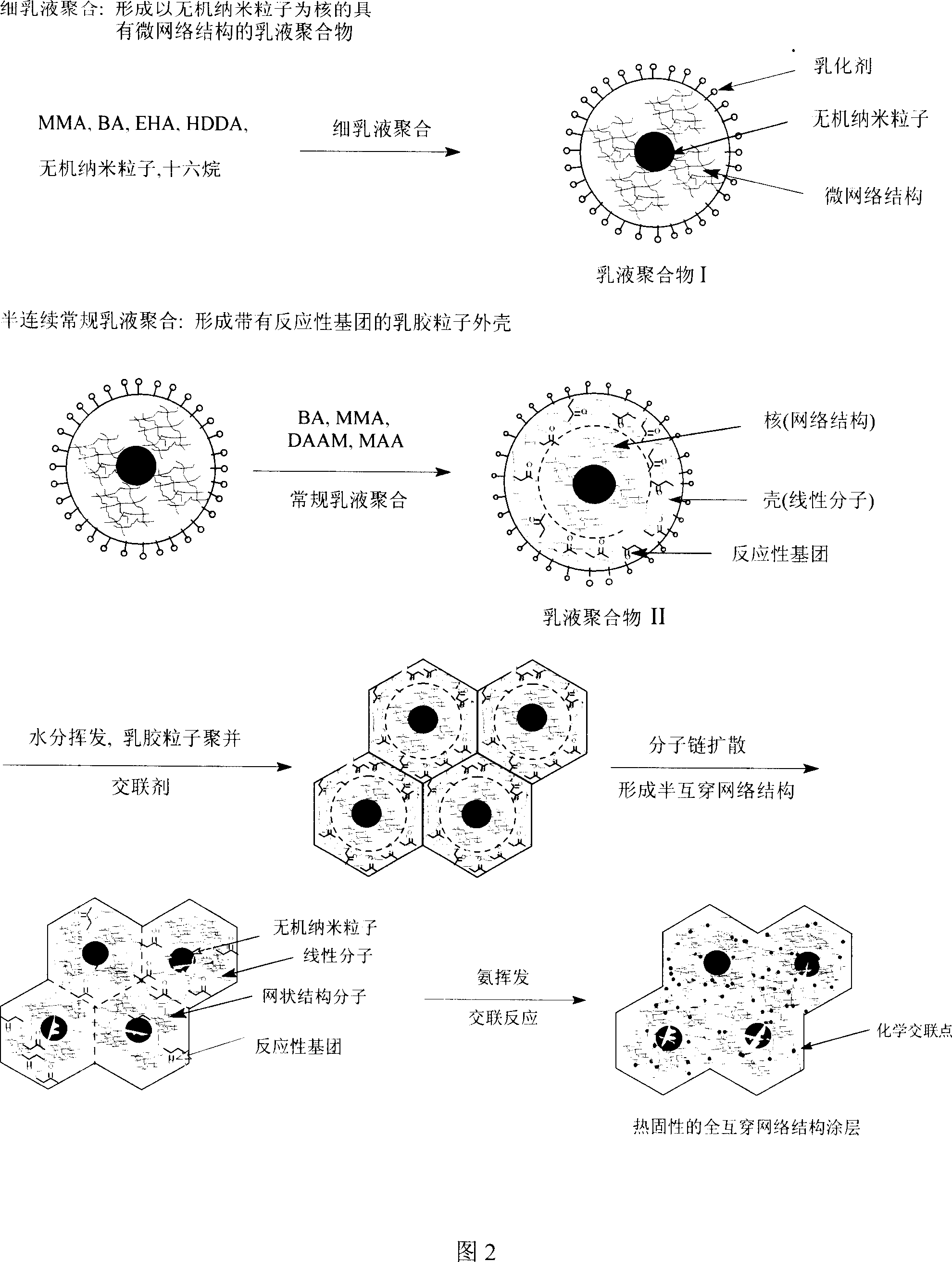

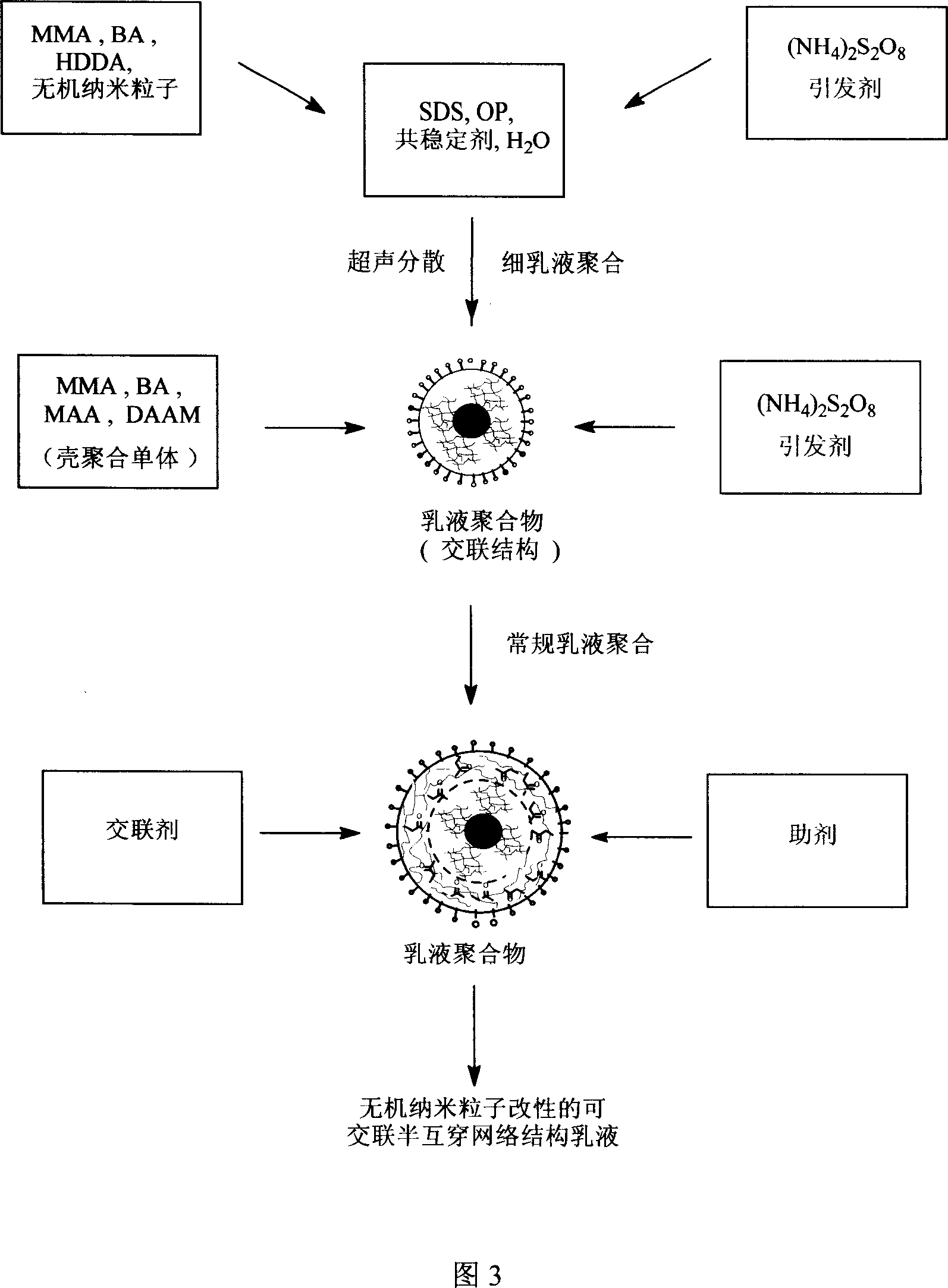

Method used

Image

Examples

Embodiment 1

[0057] Mix 21.6.g of methyl methacrylate, 23.4g of butyl acrylate, 1.5g of 1,6-hexanediol diacrylate, 5.0g of nano-silicon dioxide, and 1.5g of hexadecane, and stir at high speed after ultrasonic dispersion poured into 120mL water dissolved with 0.49g sodium lauryl sulfate, 1.45g polyethylene glycol octylphenyl ether and 0.15g sodium bicarbonate buffer, pre-emulsified for 15min, and then ultrasonically dispersed for 30min to obtain Predispersed nucleomonomers. In a 500mL three-necked reactor equipped with a mechanical stirrer, condenser and constant pressure funnel, add the above-mentioned pre-dispersed nuclear mixed monomer, stir at a low speed, raise the temperature to 76°C, add 0.15g of initiator ammonium persulfate to initiate the polymerization reaction, After the reaction system turned blue and the monomer reflux disappeared, the reaction was continued for 2 h to obtain emulsion polymer I.

[0058] Dissolve 5.8g of diacetone acrylamide in a mixed solution of 28.5g of me...

Embodiment 2

[0060] Mix 21.6g of methyl methacrylate, 23.4g of butyl acrylate, 1.5g of 1,6-hexanediol diacrylate, 5.0g of nano-titanium dioxide, and 1.5g of cetyl alcohol. After ultrasonic dispersion, under high-speed stirring, pour Put into 120mL water dissolved with 0.49g sodium lauryl sulfate, 1.45g polyethylene glycol octylphenyl ether and 0.15g buffer sodium bicarbonate, pre-emulsify for 15min, and then ultrasonically disperse for 30min to obtain pre-dispersed nucleomonomer. In a 500mL three-necked reactor equipped with a mechanical stirrer, a condenser and a constant pressure funnel, add the above-mentioned pre-dispersed nuclear monomer, stir at a low speed, heat up to 76°C, add 0.15g of initiator ammonium persulfate to initiate the polymerization reaction, wait The reaction system turned blue, and after the reflux of the monomer disappeared, the reaction was continued for 2 hours to obtain the emulsion polymer I.

[0061] Dissolve 6.5g of diacetone acrylamide in a mixed solution of...

Embodiment 3

[0063] Mix 21.6g of methyl methacrylate, 23.4g of butyl acrylate, 1.5g of triethylene glycol diacrylate, 5.0g of nano-silica, and 1.5g of hexadecane. After ultrasonic dispersion, under high-speed stirring, Pour into 120mL water dissolved with 0.49g sodium lauryl sulfate, 1.45g polyethylene glycol octyl phenyl ether and 0.15g buffer sodium bicarbonate, pre-emulsify for 15min, and then ultrasonically disperse for 30min to obtain pre-dispersion nucleosomes. In a 500mL three-necked reaction kettle equipped with a mechanical stirrer, a condenser and a constant pressure funnel, add the above-mentioned pre-dispersed nuclear monomer, stir at a low speed, raise the temperature to 76 ° C, add 0.15 g of initiator ammonium persulfate to initiate the polymerization reaction, wait The reaction system turned blue, and after the reflux of the monomer disappeared, the reaction was continued for 2 hours to obtain the emulsion polymer I.

[0064] Dissolve 6.2 g of acetoacetoxyethyl methacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com