Electrode array microchip sensor, preparation method and application therefor

An electrode array and microchip technology, used in instruments, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of system target measurement accuracy error, detection system interference, increase detection cost, etc., and achieve industrialized batch size. The effect of reducing the cost of detection and production, low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

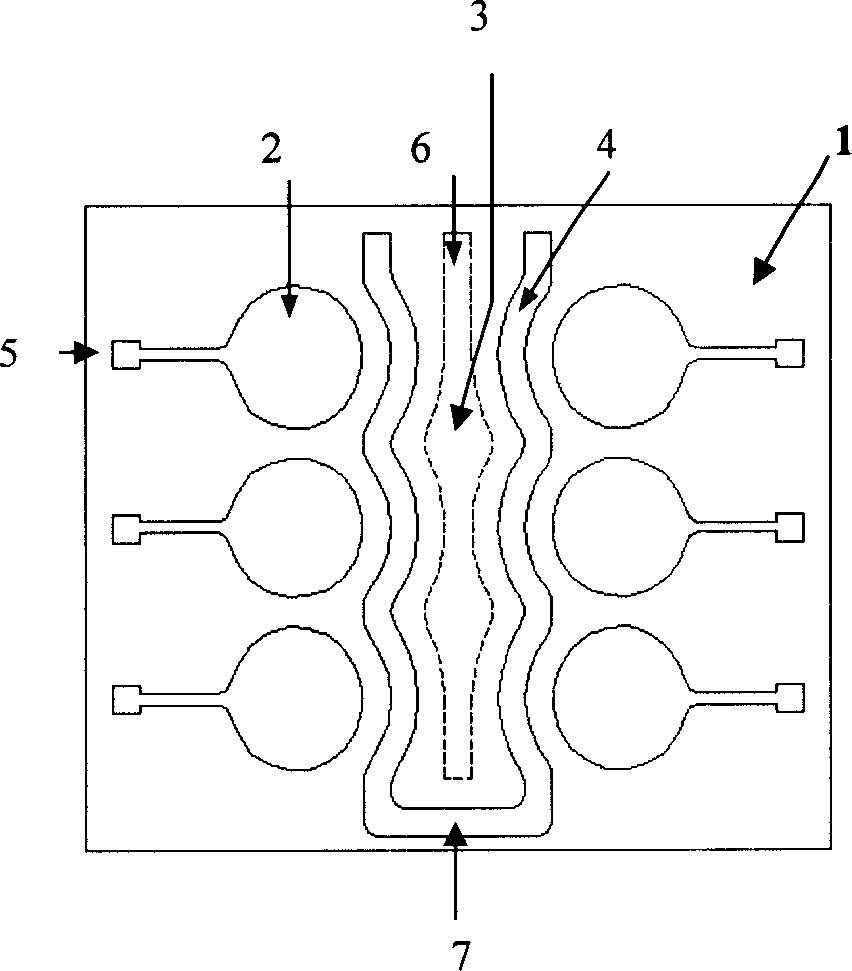

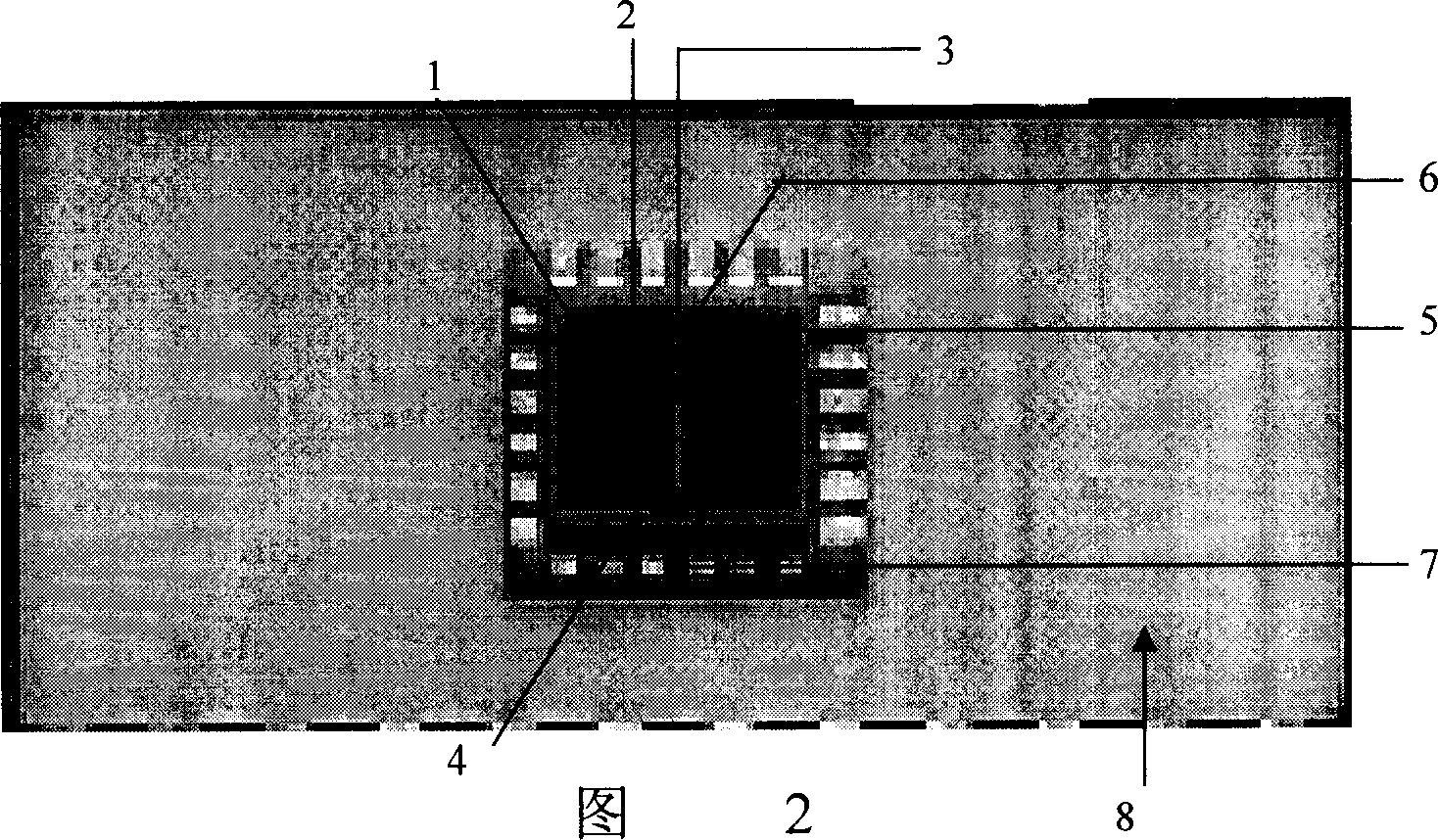

[0049] Embodiment 1 Fabrication of Electrode Array Microchip Sensor

[0050] 1. Pretreatment of monocrystalline silicon wafers

[0051] (1) Cleaning the surface of a single crystal silicon wafer with a diameter of 2.5-7.5 inches is first cleaned according to the following process. 1# liquid (NH 3 :H 2 o 2 :H 2 O=1:2:7) boiled for 10 minutes, rinsed with deionized water for 15 minutes; then use 2# liquid (HCl: H 2 o 2 :H 2 (0=1:2:7) was boiled for 10 minutes, rinsed with deionized water for 15 minutes, and dried under an infrared lamp.

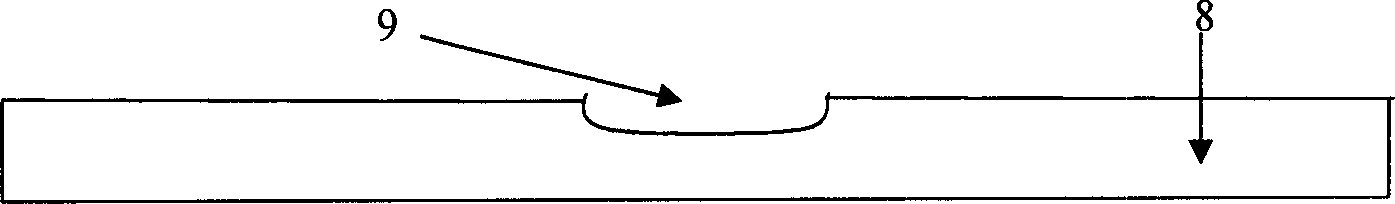

[0052] (2) Oxidation to generate SiO 2 Insulating substrate: In the domestic oxidation furnace, in the presence of oxygen, a layer of SiO with a thickness of about 500 nanometers is formed by thermal oxidation at 500 °C 2 TLC.

[0053] 2. Electrode fabrication

[0054] (1) The production of the working electrode and the counter electrode uses the German Karl Hughes photolithography machine for the first photolithography (the remainin...

Embodiment 2

[0058] Example 2 High-throughput detection of multiple disease markers in human serum samples

[0059] 1. Fabrication of Multichannel Electrode Array Microchip Sensors

[0060] Referring to the method of Example 1, a 6-channel electrode array microchip sensor was fabricated.

[0061] 2. Generation of Antibody-Polymer Membrane

[0062] Add 50 microliters of 10 millimolar pH 7.0 phosphate buffer solution containing 10 millimolar o-phenylenediamine polymerizable monomer and 3 micrograms / ml antibody to be copolymerized into the electrolytic cell formed on the surface of the microchip sensor . Connect each lead wire of the electrode array microchip sensor to the corresponding working electrode, counter electrode and reference electrode connection port of the multi-channel electrochemical workstation. Antibody-polymer films were generated by cyclic voltammetry (CV) at room temperature. The experimental conditions are as follows: scanning range (0-0.8V), scanning speed (100 mV / s)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com