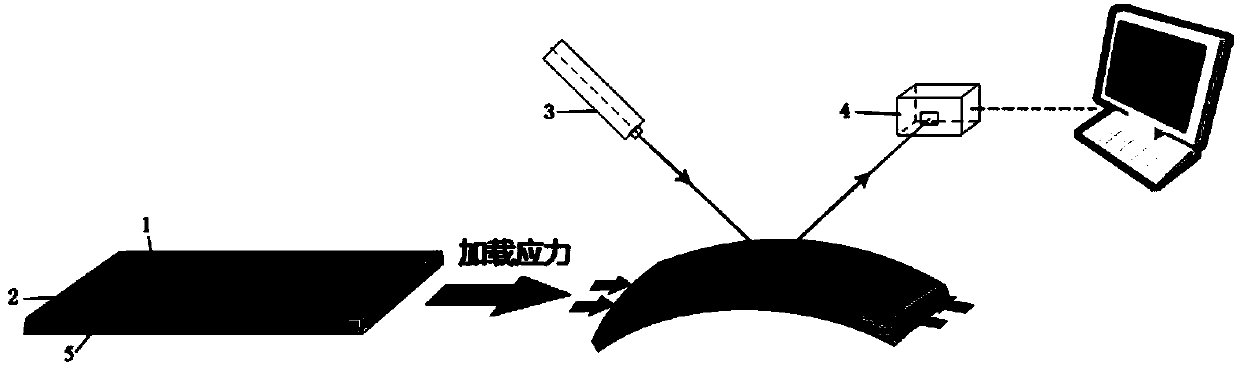

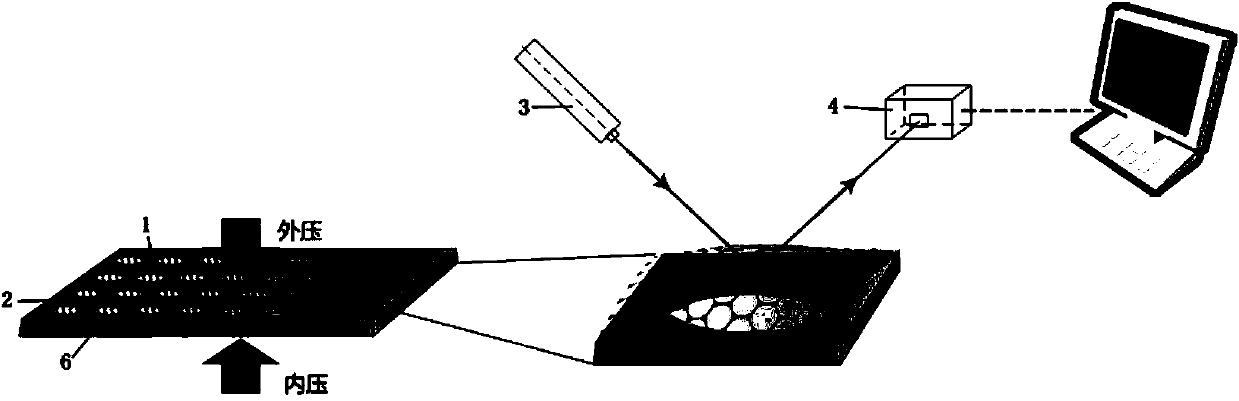

Device for measuring object stress by utilizing graphene membrane, and preparation method and testing method of device

A graphene film and graphene technology, which can be used in measurement devices, measurement of elastic deformation force by measuring gauges, and optical devices, etc., can solve problems such as complicated processes and limited structures to be measured, and achieve easy operation and adaptability. Strong and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

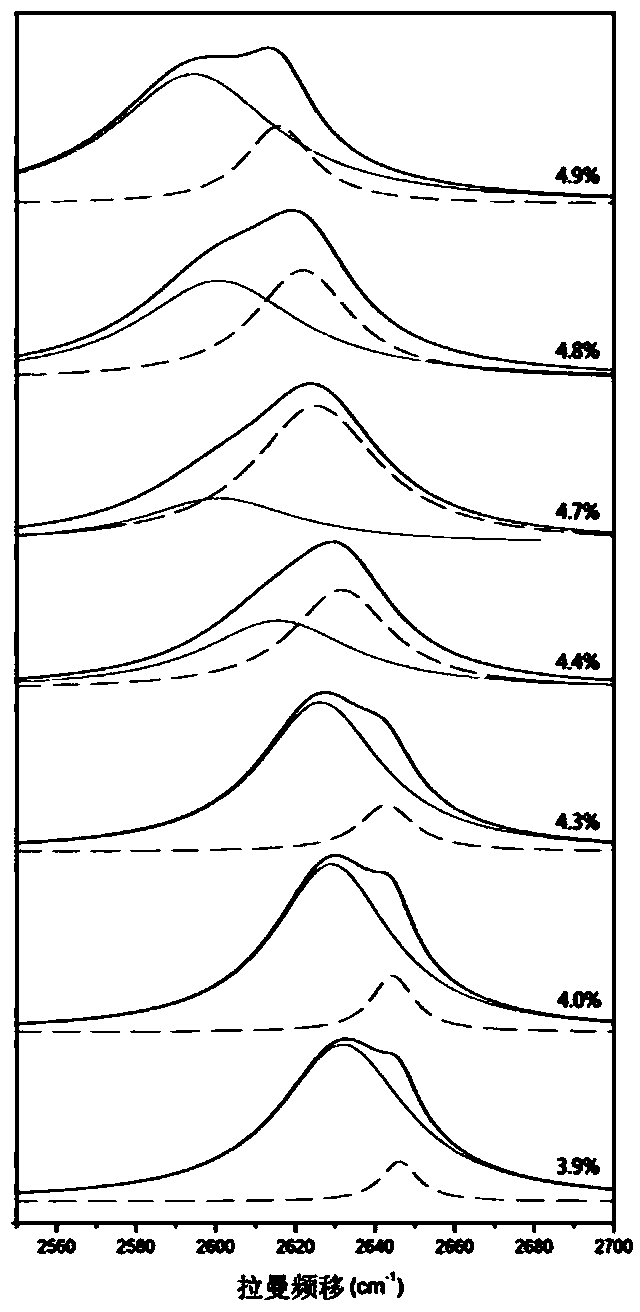

Examples

preparation example Construction

[0039] The present invention also proposes a method for preparing a device utilizing a graphene film to measure the stress of an object, comprising the following steps:

[0040] 1) Use chemical vapor deposition method or plasma-assisted chemical vapor deposition method to grow single-layer or double-layer graphene on the surface of copper foil with a thickness of 10-30 μm, wherein the purity of copper foil is more than 99%; use chemical vapor deposition method When depositing graphene, the copper foil was heated at 1000 °C in H 2 Keep in the atmosphere for 20-30min, then pass CH 4 and H 2 mixed gas, CH 4 The flow rate is controlled at 10~30sccm, H 2 The flow rate is controlled at 40 ~ 100sccm; then after keeping at 1000°C for 10min, first close the CH 4 , at H 2 Under the atmosphere, the temperature is lowered to 25°C at a rate of 1°C / s to prepare single-layer or double-layer graphene.

[0041] 2) Spin-coat PMMA, PDMS, PVDC or PET on the surface of graphene, and then use...

Embodiment 1

[0045] 1) Chemical vapor deposition method (CVD) to grow single-layer or double-layer graphene: the substrate is a strip of copper foil of 25 μm (thickness) × 10 mm (width) × 50 mm (length), with a purity of 99.8%; 2 Keep at 1000°C for 20min under the atmosphere. Then, pass into CH 4 and H 2 mixed gas, CH 4 The flow rate is controlled at 15sccm, H 2 The flow control is at 40sccm, 1000°C for 10 minutes, then close the CH 4 , at H 2 Under the atmosphere, the temperature is cooled to 25°C at a rate of 1°C / s to obtain single-layer or double-layer graphene.

[0046] 2) Spin-coat 200nm-thick SU8 photoresist (SU82000.5MicroChem) on the copper foil cut from step 1) with a size of 5mm×25mm, then spin-coat a layer of PMMA, dry and place in 0.3mol / L and FeCl with a small amount of dilute hydrochloric acid 3 About 3 hours in the aqueous solution, until the copper foil is completely dissolved, and the graphene / PMMA film layer is obtained, which floats on the surface of the solution...

Embodiment 2

[0049] 1) Chemical vapor deposition method (CVD) to grow single-layer or double-layer graphene: the substrate is a strip of copper foil of 25 μm (thickness) × 10 mm (width) × 50 mm (length), with a purity of 99.8%; 2 Keep at 1000°C for 20min under the atmosphere. Then, pass into CH 4 and H 2 mixed gas, CH 4 The flow rate is controlled at 15sccm, H 2 The flow control is at 40sccm, 1000°C for 10 minutes, then close the CH 4 , at H 2 Under the atmosphere, the temperature is cooled to 25°C at a rate of 1°C / s to obtain single-layer or double-layer graphene.

[0050] 2) Spin-coat 200nm-thick SU8 photoresist (SU82000.5MicroChem) on the copper foil cut from step 1) with a size of 5mm×25mm, then spin-coat a layer of PMMA, dry and place in 0.3mol / L and FeCl with a small amount of dilute hydrochloric acid 3 About 3 hours in the aqueous solution, until the copper foil is completely dissolved, and the graphene / PMMA film layer is obtained, which floats on the surface of the solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com