System and method for employing a resonant scanner in an X-Y high speed drilling system

A technology of scanners and scanning units, applied in the direction of instruments, manufacturing tools, optical components, etc., can solve the problems of adding motors, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

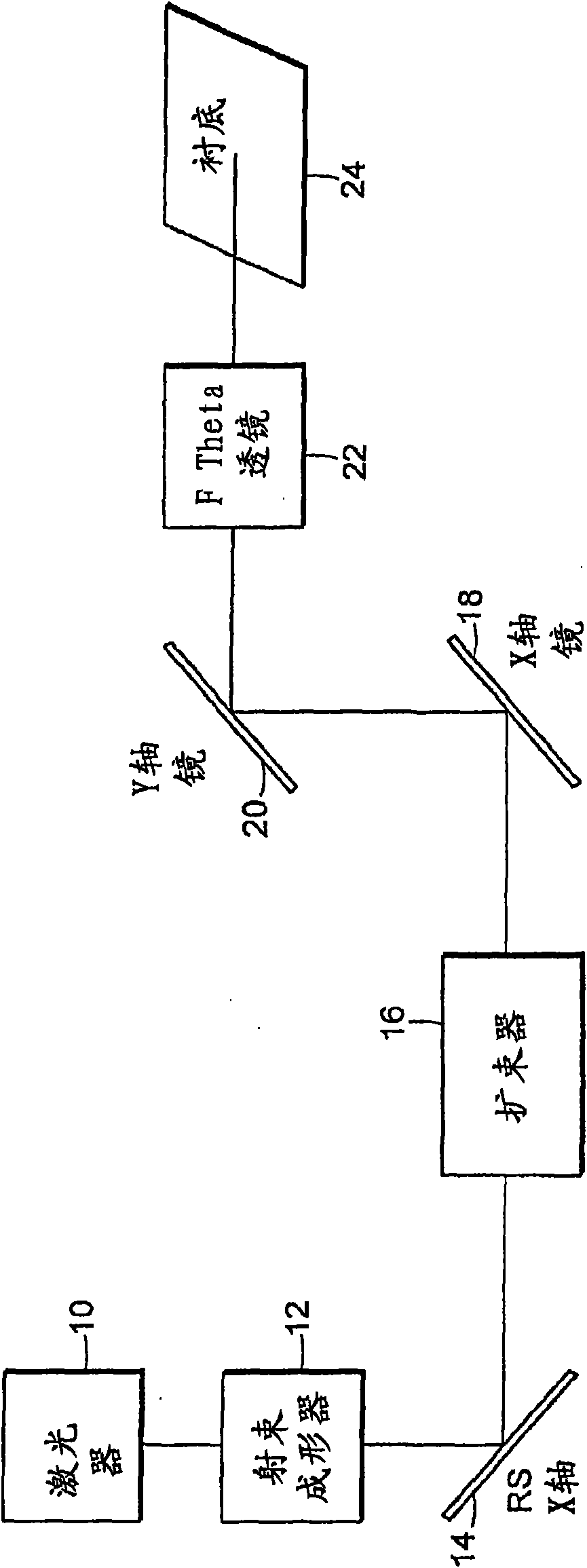

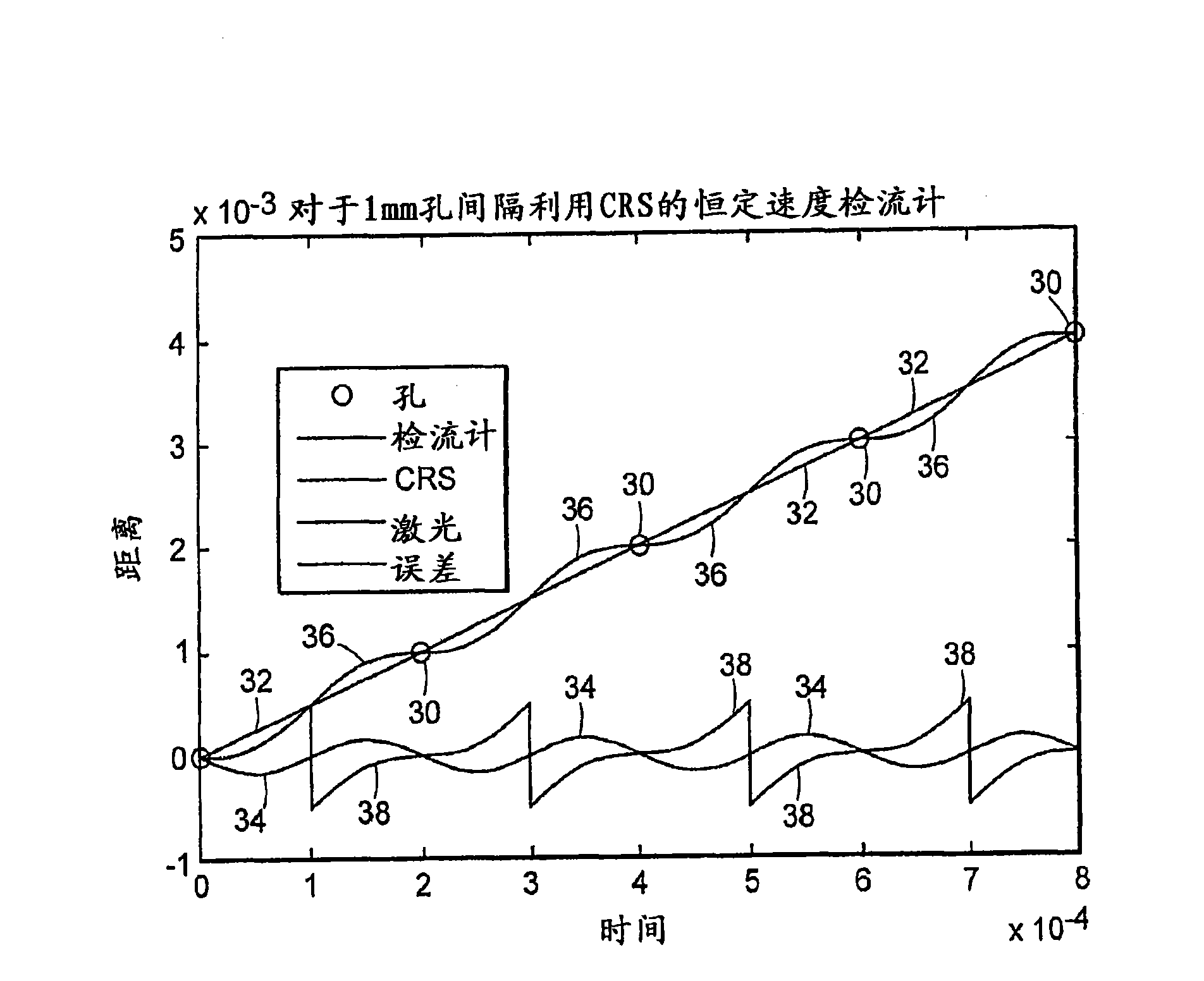

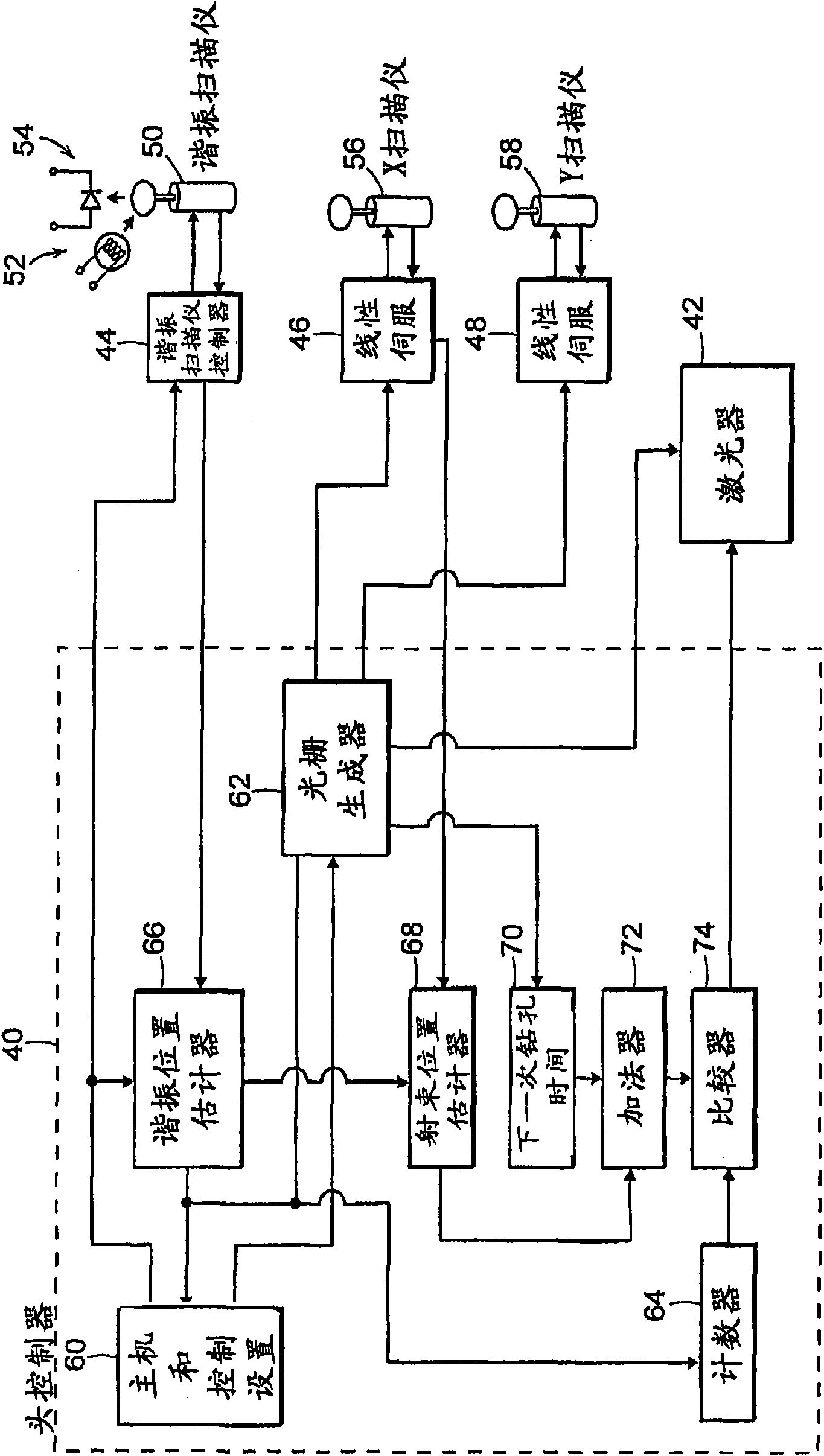

[0016] In many applications, the regions of the target substrate to be drilled with holes are arranged such that there will be clusters of closely spaced holes along a row, where the spacing is much smaller than the field size. In these cases, it is possible to use limited rotation motors in constant speed mode combined with high speed scanners to produce faster drilling rates. The scanner can be an acousto-optic deflector, an electro-optic deflector, a rotating polygon, an additional galvanometer optical scanner, or a resonant scanner.

[0017] Additional scanners require high speed but much smaller angular path, so placement in front of a beam expander requiring a small aperture may be optimal in certain applications. Overall, the amount of time a mirror can move is proportional to the size of the aperture. Smaller aperture, higher speed systems can be provided by placing high speed scanning elements in front of the beam expander. Other advantages of such a system include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com