Hydraulic power depressurization acceleration tool for deep drilling well bottom

A drilling and power technology, which is applied in the field of deep well drilling bottom-hole hydrodynamic depressurization and speed-up tools, can solve the problems of hindering the timely removal of bottom-hole cuttings, affecting the rock breaking efficiency of the drill bit, and increasing the wear of the drill bit, so as to improve the efficiency of rock breaking, The effect of prolonging the life of the drill bit and increasing the ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

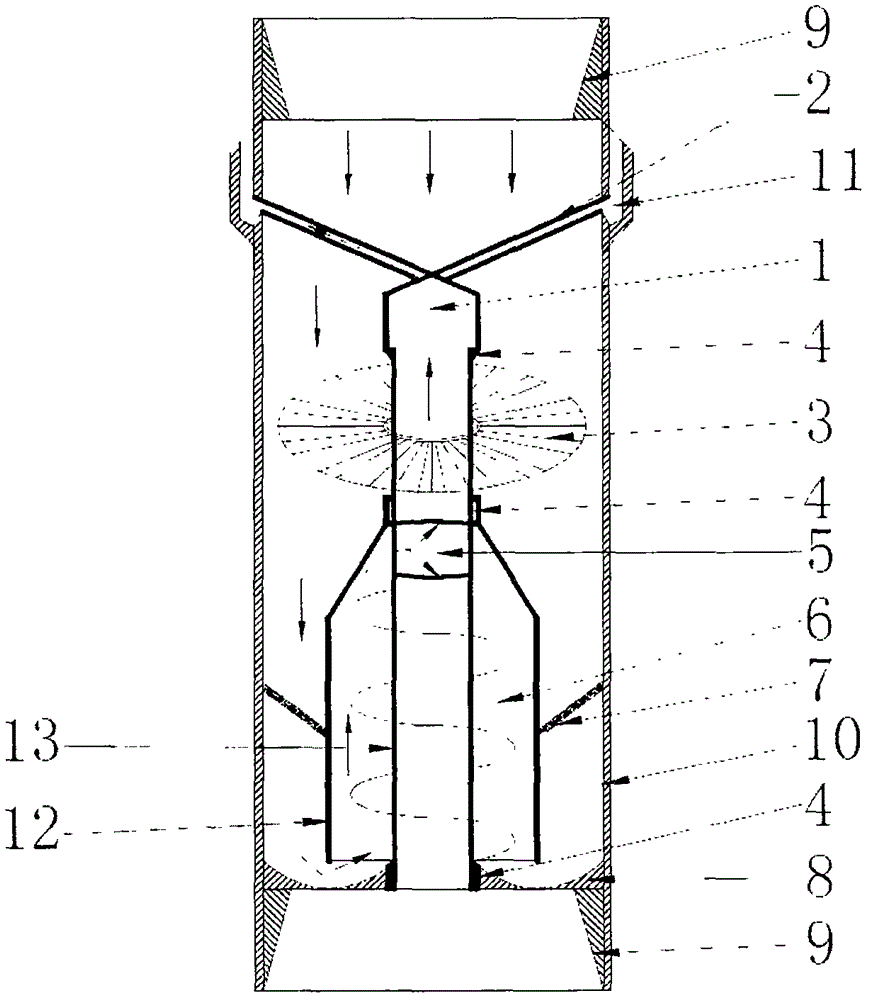

[0018] The following is attached figure 1 , describe the present invention in detail, as follows:

[0019] The deep well drilling bottom hole hydrodynamic decompression and speed-up tool consists of a solid phase collector 1, a solid guide tube 2, a turbo accelerator 3, a rotary sealer 4, a power connector 5, a cyclone separator 6, a support rod 7, and a deflector 8. Thread 9, drill pipe 10, solid discharge nozzle 11, external conical steel shell 12 of cyclone separator, and cyclone rotor 13.

[0020] The high-pressure and high-speed drilling fluid pumped into the ground through ground pressure impacts the turbo accelerator 3, and the axial flow of the drilling fluid drives the turbo accelerator 3 to rotate. The turbo accelerator 3 rotates at the same speed; the drilling fluid passing through the turbo accelerator 3 flows down along the gap between the inner wall of the drill pipe 10 and the cyclone accelerator, passes through the deflector 8 to buffer and change direction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com