Negative pressure sucking method for recovering waste gas and swarf for high speed drilling

A suction, negative pressure technology, used in drilling/drilling equipment, chemical instruments and methods, maintenance and safety accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

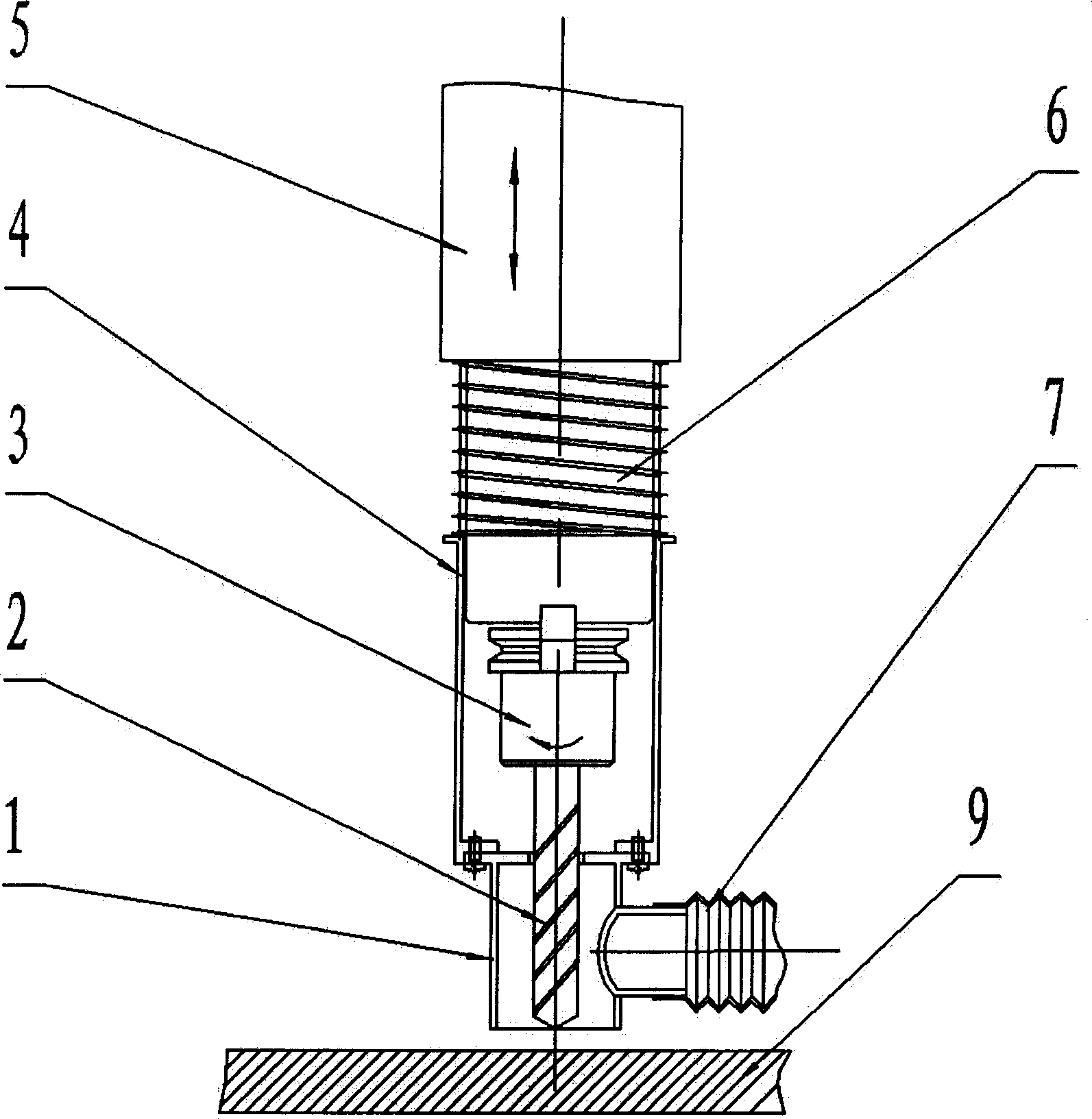

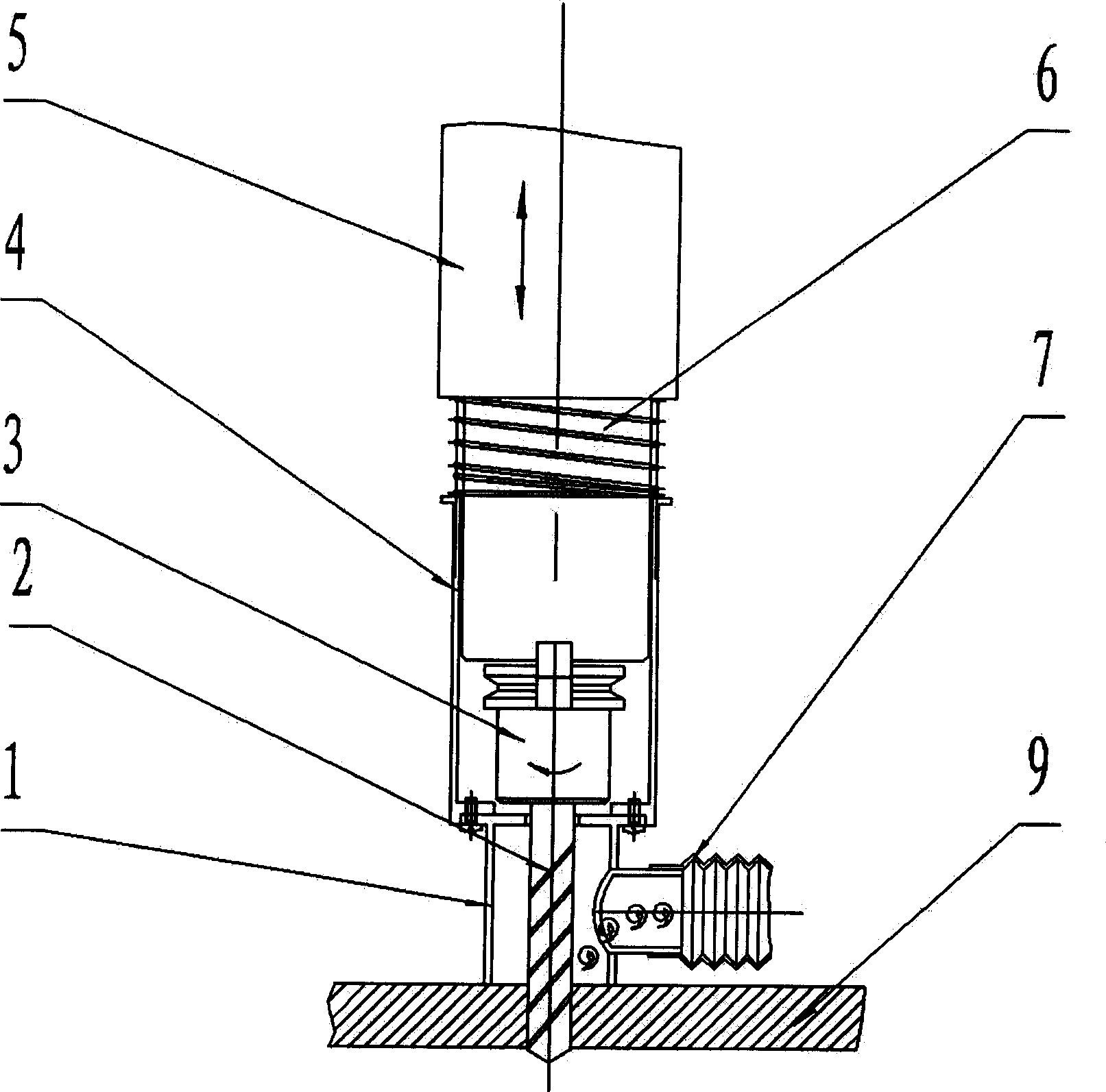

[0018] Such as figure 1 As shown, the device used for high-speed drilling negative pressure suction exhaust gas and chip recovery method includes front cylindrical sleeve 1, high-speed drill bit 2, drill chuck 3, connecting sliding sleeve 4, lifting spindle box 5, and compression spring 6 , Suction hose 7 and so on.

[0019] High-speed drilling negative pressure suction waste gas and chip recovery method, the specific implementation method is: add a cylindrical sleeve 1 to the front end of the drill shaft box 5, the diameter of the inner cavity of the cylindrical sleeve 1 is 2 to 2.5 of the diameter of the drill bit 2 times, the front end of the cylindrical sleeve 1 is adjusted to the same height as the cutting edge of the drill bit 2, and the rear end of the cylindrical sleeve 1 is connected with the connecting sliding sleeve 4, and together with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com