Downhole compression torsion balancing tool

A balance and tool technology, applied in the direction of drilling tools, drilling equipment, drilling automatic control system, etc., can solve problems such as tool surface instability, excessive torque, slipping, etc., to reduce construction risks, ensure build-up rate, reduce The effect of small directional influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

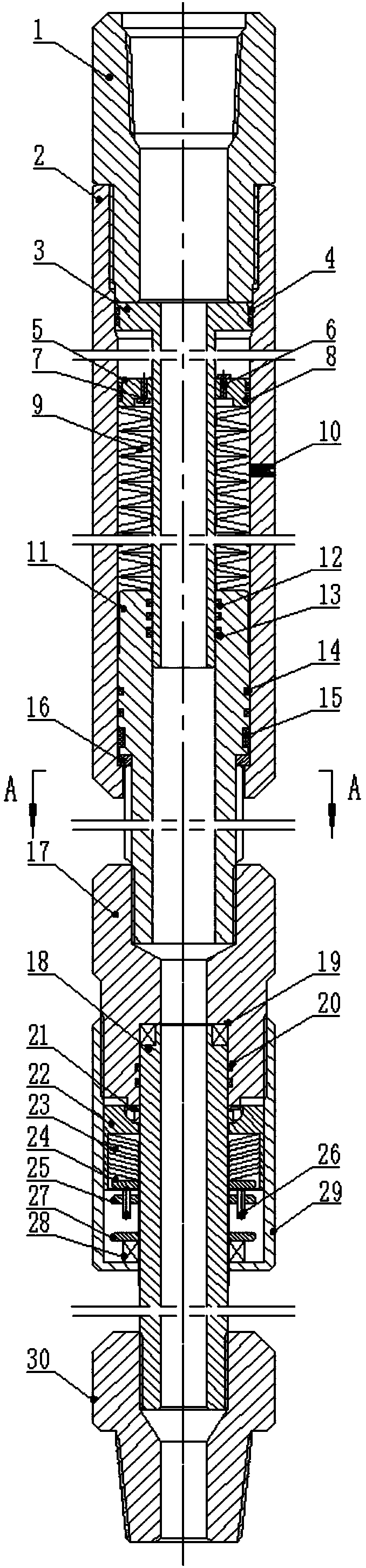

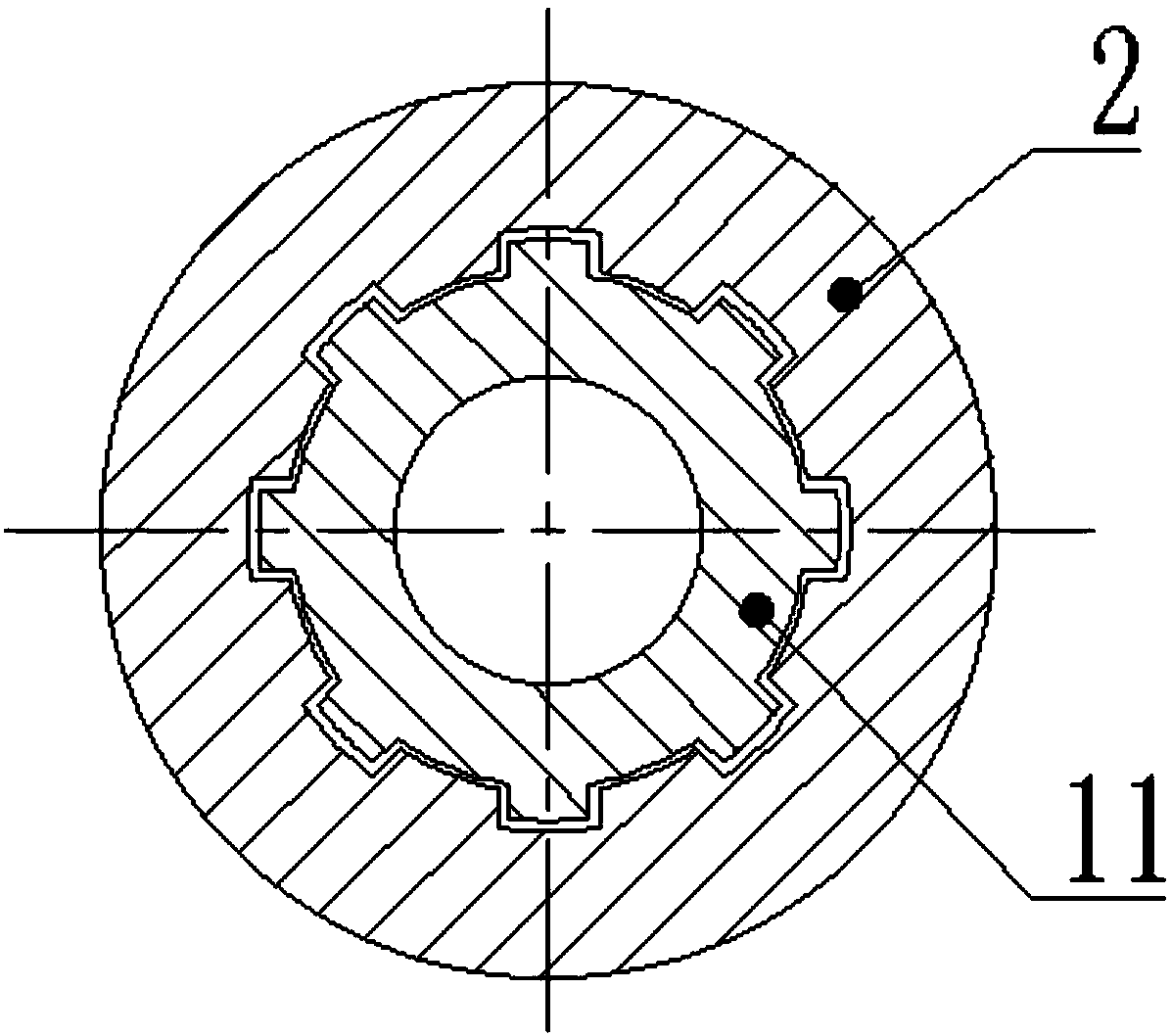

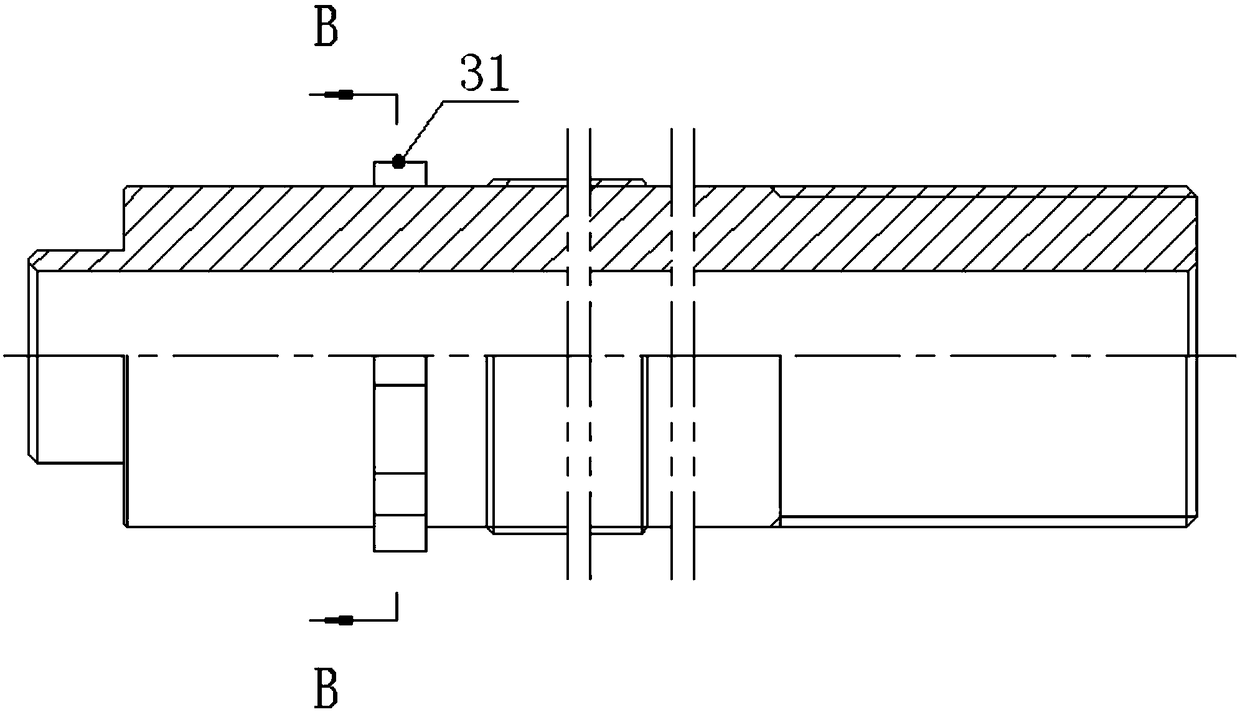

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a downhole pressure torsion balance tool includes an upper joint 1 and a hydraulic cylinder liner 2, the lower end of the upper joint 1 is connected to the liquid cylinder liner 2; the central pipe I3 is installed in the liquid cylinder liner 2, and the upper end of the central pipe I3 is provided with a The sealing boss between the inner walls of the cylinder liner 2, the center pipe I3 is connected with the stop ring I5, the upper damping chamber is formed between the center pipe I3, the liquid cylinder liner 2 and the upper end of the stop ring I5, and the upper end of the center pipe II11 is set on the center pipe I3 The outer side of the lower end can move up and down along the central tube I3, and the elastic mechanism I9 is installed between the upper end surface of the central tube II11 and the retaining ring I5. 2 moves up and down and can rotate with the cylinder liner 2, the lower dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com