A string structure for enhancing the horizontal extension capability of coiled tubing drilling

A horizontal extension and pipe string technology, which is applied in the direction of drilling equipment, drill pipe, casing, etc., can solve the problems of poor horizontal extension ability, spiral bending, and easy accumulation of cuttings, so as to reduce the deposition of cuttings and enhance the ability of horizontal extension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

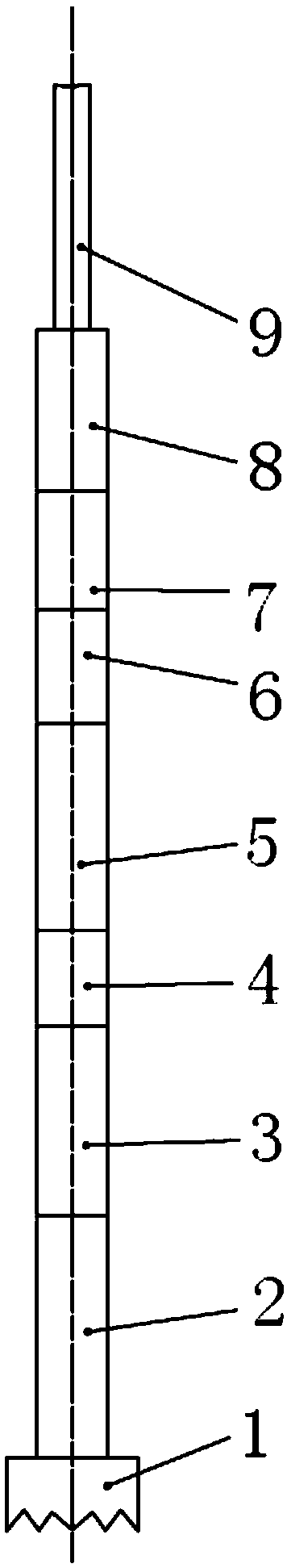

[0009] like figure 1 As shown, a pipe string structure that enhances the horizontal extension capability of coiled tubing drilling includes a drill bit 1, a power drilling tool 2, a measurement-while-drilling assembly 3 and a coiled tubing 9. The upper end of the drill bit 1 is connected to the power drilling tool 2, and the upper end of the power drilling tool 2 is Connect the measurement while drilling component 3; the upper end of the measurement while drilling component 3 is connected to the WOB automatic control nipple 4, the WOB automatic control sub 4 communicates with the measurement while drilling component 3 and can automatically control the WOB, and keep it relatively constant to ensure that the drill bit 1 Drilling rapidly under suitable weight-on-bit conditions.

[0010] The upper end of the pressure-on-bit automatic control nipple 4 is connected to the downhole rotary power device 6. The downhole rotary power device 6 can generate a rotational torque similar to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com